- About us

- Company details

COMEC Innovative S.r.l manufactures special machines for composites. Our main technilogies are Towpreg, Prepreg, Filament Winding, ATL and AFP machines for a mass production based upon more than 50 years of experience in machines assembling. We are involved in innovative projects for hydrogen, regarding Dry Filament Winding and Aerosol Jet Printing technologies.

Year of establishment:

1965

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2001

Export turnover:

Not available

Activities:

Manufacture of metal forming machinery and machine tools

Manufacture of metal forming machinery and machine tools for metal work

Repair and maintenance of other special-purpose machinery nec

Installation of other industrial machinery and equipment

- Videos

- Catalogue

No videos uploaded

No documents uploaded

- Contact Information

- Business Proposals

Company:

" COMEC - COSTRUZIONI MECCANICHE INNOVATIVE S.R.L." OVVERO " COMEC INNOVATIVE S.R.L. "

Web site:

Address:

VIA PAPA LEONE XIII 34

City:

SCALO CHIETI (CH)

Zip Code:

66100

Social media:

Tag:

No business proposals uploaded

- Map

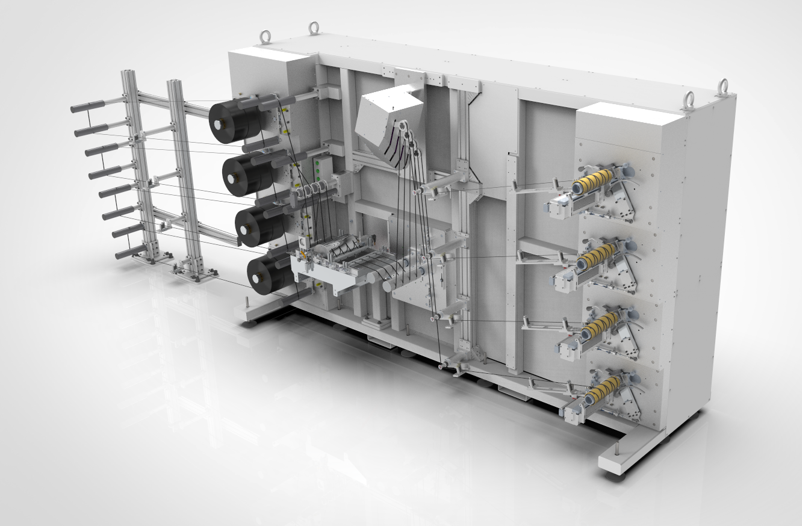

Towpreg Machine

Towpreg technology is the one in which we are the most experienced in. Over the years we have managed to build a four-line machine that reaches very high process speeds of 100 m/min and can produce more than 100 ton/year of towpreg (2 production shifts). The impregnation system is by a precise mechanical nozzle, depending on the type of resin to be used. It will also be possible to integrate a humidity-controlled cooling chamber before towpreg rewinding if the resin needs it. In fact, some resins, for reasons of viscosity, may not let the towpreg final bobbin to unwind itself if it does not pass through the cold chamber.

Web site

https://www.comecinnovative.it/

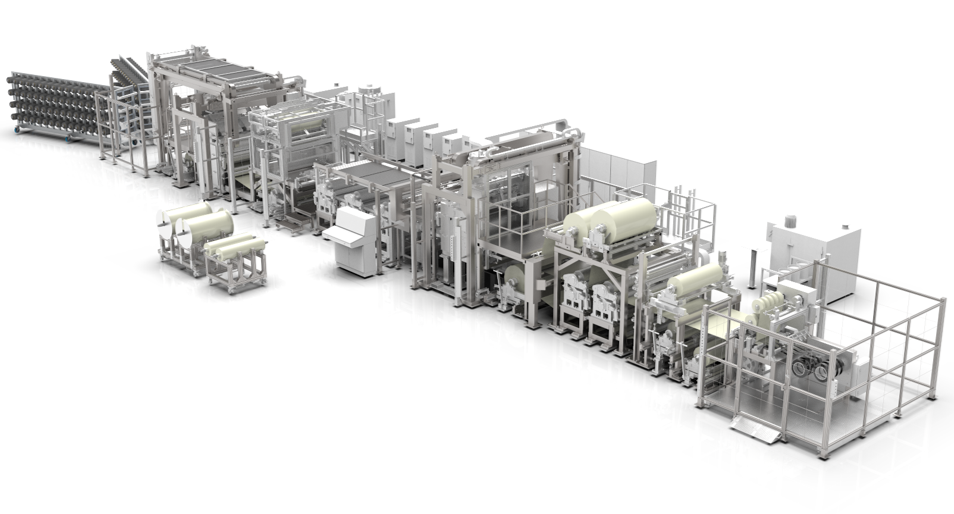

Prepreg Machine

Comec is experienced in Prepreg machines manufacturing too, which can impregnate various types of fibres (carbon, glass, natural) to produce prepregs, using hotmelt epoxy thermoset resins. The machine can reach process speed of 25 m/min. The machine shown in the picture has a modular design and could produce prepregs impregnating Fabrics or UD Tape. There are lots of implementations in this machine as Resin Film Unit, Resin Content Control system by Beta Gauge, resin content control software implementation by Neural Web, Slit Tape Cutting system.

Web site

https://www.comecinnovative.it/

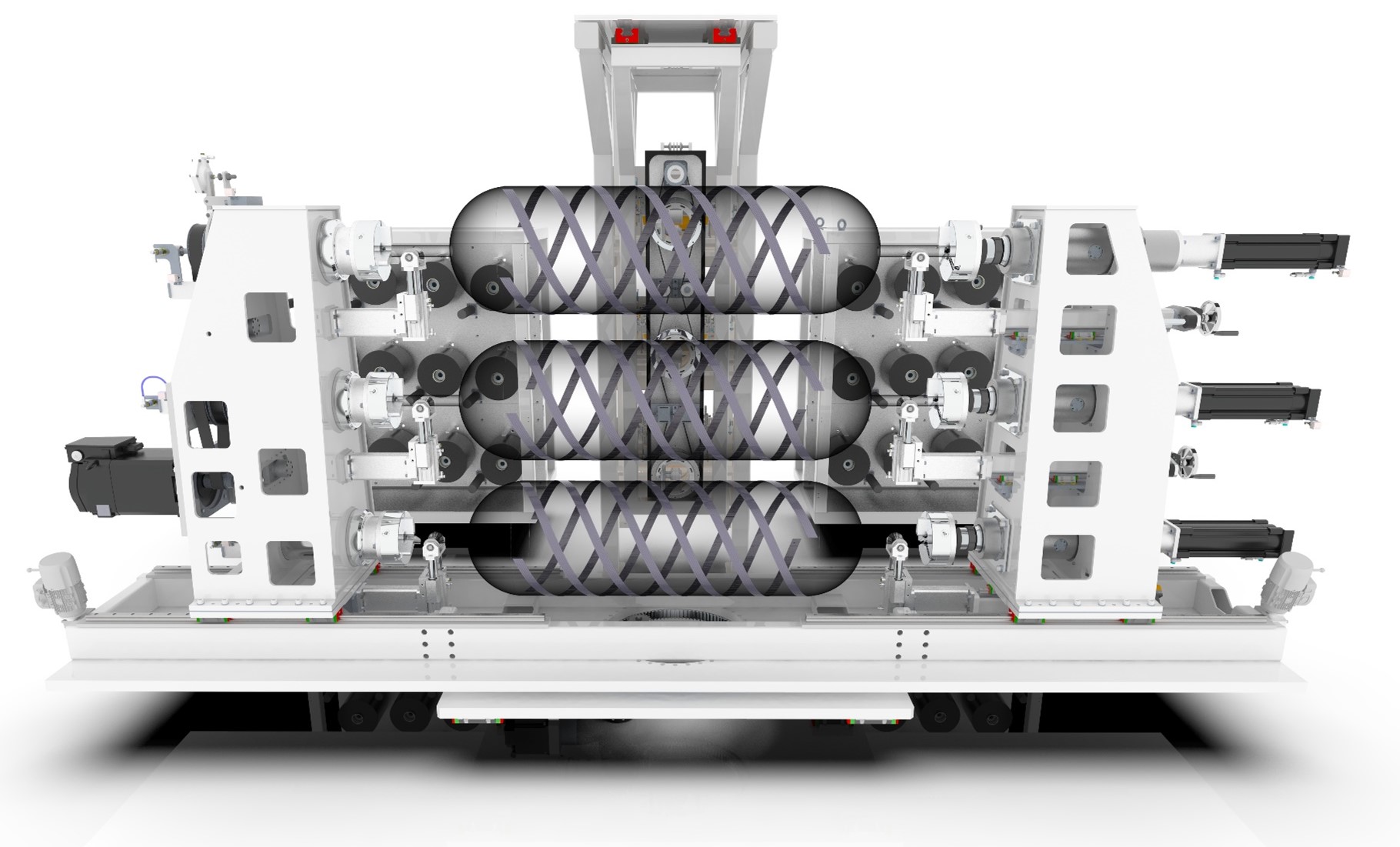

Filament Winding Machine

Basing on our experience in this technology, our R&D department is currently working on an innovative project for a Filament Winding machine to produce type IV hydrogen tanks for mobility, with pressures of up to 700 bar. These tanks will have a volume of up to 400 L, a maximum diameter of 500 mm and a length of up to 2.5 m. The technology of this machine will be towpreg winding and with it we will try to improve critical aspects of conventional Filament Winding process, which is the wet method (impregnating directly before the winding in the delivery head), such as negative speed in the dome zone.

Web site

https://www.comecinnovative.it/