- About us

- Company details

We specialise in manufacturing optimising and crosscut saws for the wood industry. Established over 35 years ago, Salvador developed in the Treviso province, an area that holds a long tradition in woodworking and in the production of tools and technologies for this industry.

Year of establishment:

1995

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2023

Export turnover:

Not available

Activities:

Manufacture of machinery and equipment nec

Manufacture of other machine tools

- Videos

- Catalogue

SUPERPUSH 150 is a true technological evolution of traditional cutting methods. It is able to increase productivity considerably, reduce staff usage to a minimum, and improve wood yield. Superpush 150 is the result of an over forty years experience working in direct contact with end users, combined with innovation and continuous technological research. It is the ideal automatic cutting centre: simple, complete, precise and productive.

Supercut 500 is a very high speed optimising saw, capable of meeting the highest production requirements with maximum reliability. Super-Fast: thanks to an exclusive double workpiece feeding system, very high acceleration and speed rates can be reached with the utmost reliability, while the innovative cutting system is so fast as to make the blade almost invisible to the human eyes. Extremely strong and reliable: sturdiness, solidity and use of materials and components that minimise subject to wear and replacement parts, thus contributing to curbing maintenance costs. Technologically innovative: Supercut 500 is an absolute leader in technology, thanks to its intelligent and exclusive software that takes advantage of all the potential offered by the simultaneous use of an innovative numerical control system and a powerful computer.

Special optimizing saw with loading system by chains.

- Contact Information

- Business Proposals

Company:

SALVADOR S.R.L.

Web site:

Address:

VIA CRISPI 19/A

City:

CODOGNE CODOGNE' (TV)

Zip Code:

31013

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Superpush 150

Superpush 150 is the direct technological evolution of traditional cutting methods, a machine able to increase productivity, reduce staff usage to a minimum and improve wood yield. It is the result of over forty years of innovation, continuous technological research and experience in direct contact with end users. It represents the ideal automatic cutting center: simple, economical, precise and productive. It’s simple and flexible: you can switch between optimized/push/stop modes with a simple touch.

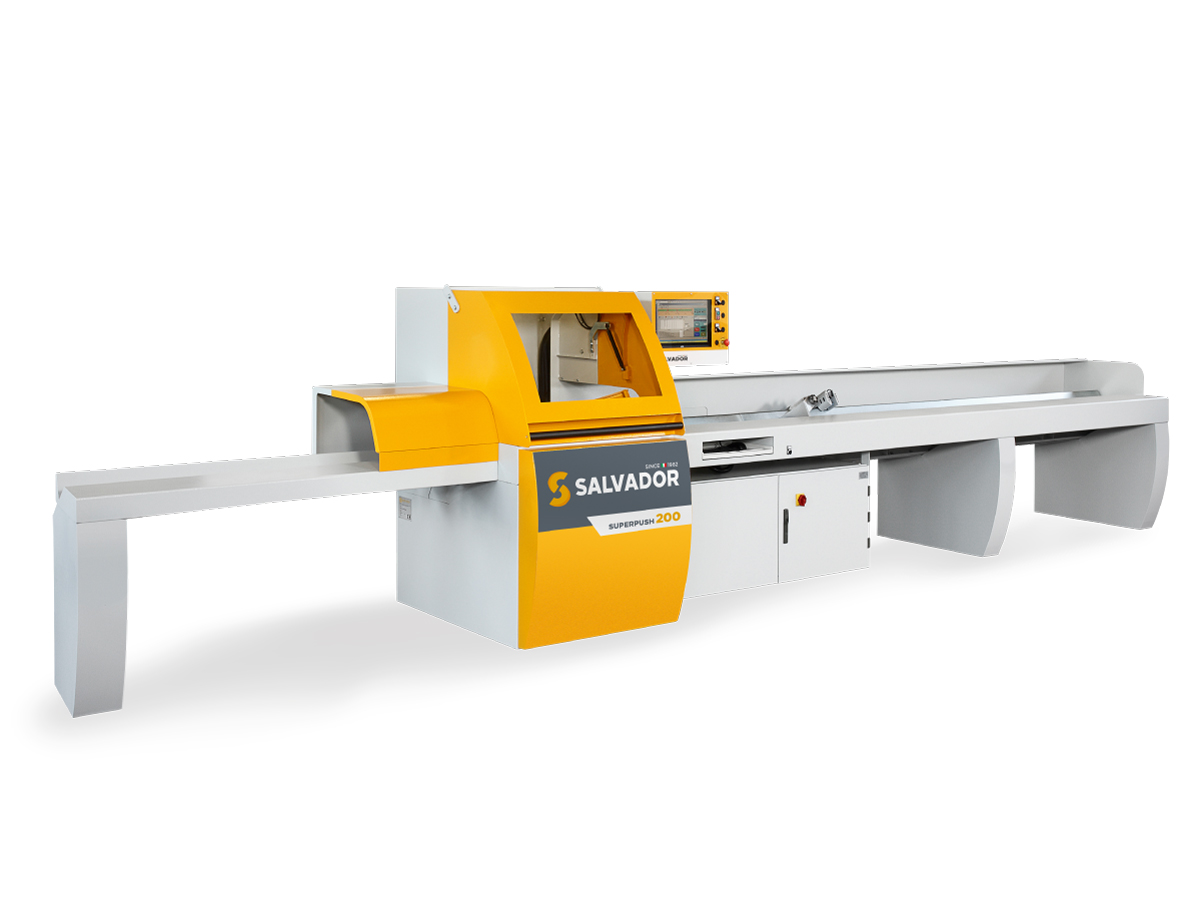

Superpush 200

Superpush 200 is the direct technological evolution of traditional cutting methods, a machine capable of boosting productivity, minimising use of labour and increasing the yield of wood. It is the result of over thirty years of innovation, continuous technological research and experience in direct contact with the end customer.

It is an ideal automatic cutting centre: simple, cost-effective, precise and highly performing.

It is simple and flexible, with no adjustments and special operating movements needed. All you need to do is put the wood onto the feeder tabletop – and Superpush 200 will take care of the rest.

Superpush 250

Superpush 250 is the direct technological evolution of traditional cutting methods, a machine capable of boosting productivity, minimising use of labour and increasing the yield of wood.

Thanks to an original feeding and loading system with chain transmission and pneumatic lifting, Superpush 250 is an ideal automatic cutting centre: simple, cost-effective, precise and highly performing.

Supercut 500

Supercut 500 is a very high speed optimising saw, capable of meeting the highest production requirements with maximum reliability.

Super-Fast: thanks to an exclusive double workpiece feeding system, very high acceleration and speed rates can be reached with the utmost reliability, while the innovative cutting system is so fast as to make the blade almost invisible to the human eyes.

Extremely strong and reliable: sturdiness, solidity and use of materials and components that minimise subject to wear and replacement parts, thus contributing to curbing maintenance costs.

Technologically innovative: Supercut 500 is an absolute leader in technology, thanks to its intelligent and exclusive software that takes advantage of all the potential offered by the simultaneous use of an innovative numerical control system and a powerful computer.

Superangle 600

Superangle 600 is an ideal cutting centre for angular, optimised cuts. The direct technological evolution of traditional cutting methods, Superangle 600 can boost productivity, guarantee utter precision and maintain a simple, flexible process logic.

Fast and precise: the tilting table is mounted on an innovative high-precision mechanical structural system, which guarantees exact angles, and is controlled directly by a technologically cutting-edge, powerful electronic motor, even during braking. As a result of combining these two innovative, highly technological solutions, Superangle 600 can reach the highest operating speed while ensuring maximum precision.