- About us

- Company details

Plastiblow and extrusion blow-moulding technology

40 years of experience in the design and production of blowing machines. A competence available to many industrial sectors for the production of single or multi-layer containers.

Innovation and evolution; these two words sum up half a century of work for Plastiblow. Founded in 1981, today is a leading reality in the field of electric blow-moulding extrusion machines.

Experience, competence, constant evolution, great attention to the customer and ability to understand specific needs, are the ingredients that make up our business concept projected towards a new model of company.

Year of establishment:

1981

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 15 and 25 million Euro

Reference year of turnover:

2020

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of plastics and rubber machinery

Manufacture of all other various special-purpose machinery nec

Wholesale of mining, construction and civil engineering machinery

Wholesale of other machinery and equipment

Wholesale of other various machinery and equipment nec

- Videos

- Catalogue

We produce low-energy consumption full-electric extrusion blow mouding machines for the production of single or multi-layer containers up to 30L volume.

We produce All-Electric EBM machines: our experience at your service. Offices & main manufacturing facility are located in Milan- Italy. Total area of 7500 m2, including 3600 m2 of indoor area. Machine frames are manufactured in another building of 2000 m2 close to the main facility.

- Contact Information

- Business Proposals

Company:

PLASTIBLOW SRL

Web site:

Address:

VIA SALVEMINI 20

City:

CORSICO (MI)

Zip Code:

20094

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

All-Electric EBM machines

We produce extrusion blow-moulding machines with energy-saving technology.

For over 40 years we have been designing and manufacturing mechatronic blowing machines that are characterized by low energy consumption (among the lowest in the industry), precision and repeatability of movements and minimized maintenance.

Our solutions, covered by numerous patents, are appreciated by well-known industries in various sectors in many countries around the world.

In the last decade, we have implemented and applied new technologies to the whole range of extrusion blow-moulding machines, with cutting-edge solutions in the sector, that can be defined as "new generation machinery".

https://www.plastiblow.it/en/machines/electric-blow-moulding-machines

Web site

https://www.plastiblow.it/en/home

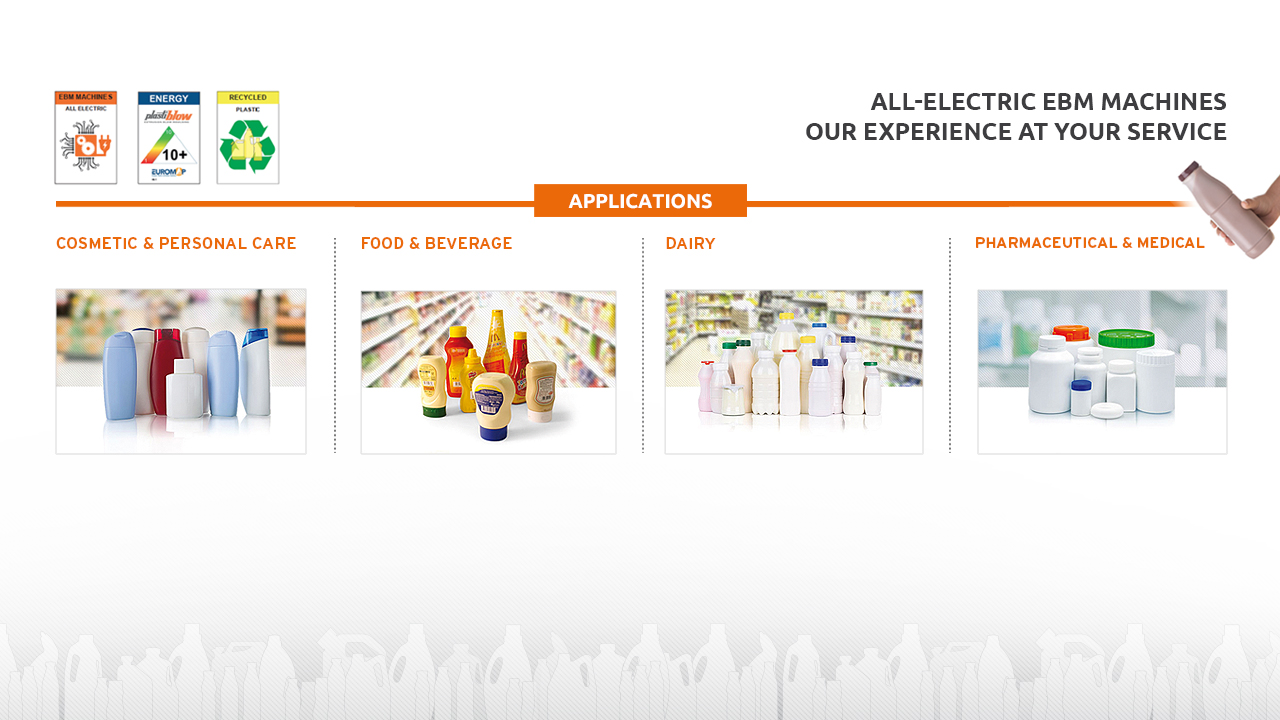

Extrusion blow moulding technology

Among the various production methods, the blow moulding extrusion technology has acquired a lot of importance for some industrial sectors considered strategic for the approach towards consumers, for the type of container design as well as for the materials used.

Sensitive to the results to be obtained. Aware of the importance of the perfection of the final product for sale to the consumer. An operational approach that characterizes us and that involves the entire organization.

Our machines are suitable for most sectors where the aesthetic quality of the container or object to be produced is of FUNDAMENTAL importance.

Cosmetic & Personal care

EXTRUSION BLOW MOULDING MACHINES FOR THE COSMETIC AND PERSONAL CARE SECTOR

The bottles and containers used in the packaging of the cosmetic sector must meet high quality and aesthetic standards. Shapes, material, surface finishes are all conditions that must meet precise requirements.

Food & Beverage

EXTRUSION BLOW MOULDING MACHINES FOR THE FOOD SECTOR

Plastiblow extrusion blow moulding machines used to produce bottles and containers for use in food packaging have to produce large quantities with very rapid and precise work cycles, to maintain the lowest possible price per unit.

Dairy

EXTRUSION BLOWING MACHINES FOR DAIRY SECTOR

Aseptic work processes and high productivity by number of pieces. These are the characteristics of the electric blow moulding machines that Plastiblow can offer to a strategic sector such as the Dairy one. Also with linear models as an alternative to rotary machines.

Pharmaceutical & Medical

BLOWING EXTRUSION MACHINES FOR THE PHARMACEUTICAL-MEDICAL SECTOR

Plastiblow extrusion blowing machines used to produce bottles and containers for medical or pharmaceutical items must undergo strict rules and approval processes.

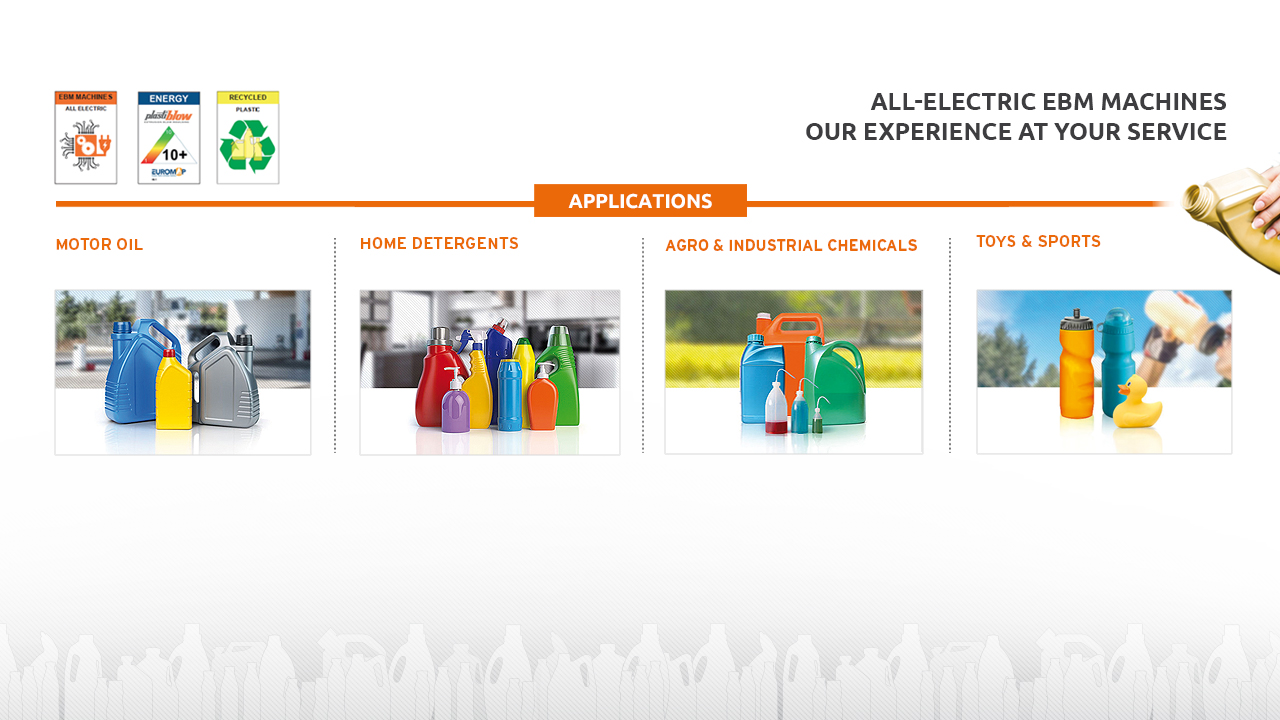

Extrusion blow moulding technology

Among the various production methods, the blow moulding extrusion technology has acquired a lot of importance for some industrial sectors considered strategic for the approach towards consumers, for the type of container design as well as for the materials used.

Sensitive to the results to be obtained. Aware of the importance of the perfection of the final product for sale to the consumer. An operational approach that characterizes us and that involves the entire organization.

Our machines are suitable for most sectors where the aesthetic quality of the container or object to be produced is of FUNDAMENTAL importance.

Motor oil

BLOWING EXTRUSION MACHINES FOR THE CAR OILS AND LIQUIDS

Plastiblow multi-cavity extrusion blow moulding machines used to produce bottles and containers for the automotive sector: high numbers, elaborate designs, perfect shapes, sealing, labeling in the mould.

Home detergents

EXTRUSION BLOW MOULDING MACHINES FOR DETERGENTS AND HOME CARE

Plastiblow extrusion blow moulding machines used to produce bottles and containers for this sector must guarantee high numbers of pieces at aggressive costs.

Agro & Industrial chemicals

EXTRUSION BLOW MOULDING MACHINES FOR THE AGROCHEMICAL AND INDUSTRIAL SECTORS

Electric blowing moulding machines replace the obsolete and large hydraulic blow moulding machines. More precision, lower energy consumption (up to 70%).

Toys & Sports

EXTRUSION BLOW MOULDING MACHINES FOR THE TOYS AND SPORTS SECTORS

For the production of items with unusual shapes, Plastiblow can develop blow moulding machines with interesting solutions characterized by a great versatility of production.

All-Electric EBM machines

Extrusion blow-moulding machines

We produce low energy consumption extrusion blow moulding machines; data among the lowest in the sector.

Once there were hydraulic machines: big, energy-consuming equipped with hydraulic units with pumps and accumulators. Then the technology came to the aid of the sector and, in early 2001 Plastiblow started to produce electric compact blow-moulding machines that were surprisingly high performance.

The models we offer are characterized by the quality of the applied technical solutions, some covered by patents, in single or double station, monolayer or multilayer coextrusion, with traditional extruders or forced feed version, for the use of high molecular polyethylene in granules or powder.

As required by the various industrial sectors, all blow-molding models can be customized.

Our range of extrusion blow moulding machines adopt new technologies in electric drives in order to get intelligent integration into industrial processes.

PB3ES-PB3ED

Stroke: 260-330 mm

Mould clamping force: 30 kN

PB6ES-PB6ED

Stroke: 300-450 mm

Mould clamping force: 60 kN

PB12ES-PB12ED

Stroke: 430-630 mm

Mould clamping force: 120 kN

PB15ES-PB15ED

Stroke: 500-800 mm

Mould clamping force: 150 kN

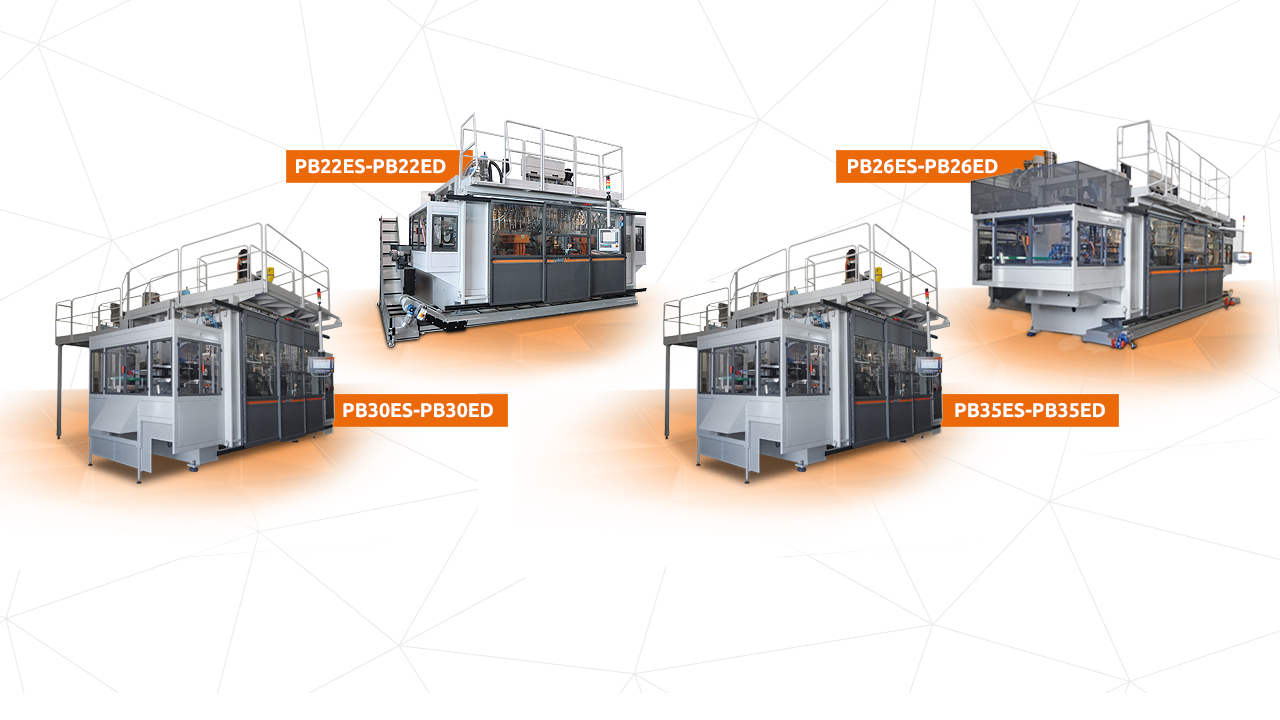

All-Electric EBM machines

Extrusion blow-moulding machines

We produce low energy consumption extrusion blow moulding machines; data among the lowest in the sector.

Once there were hydraulic machines: big, energy-consuming equipped with hydraulic units with pumps and accumulators. Then the technology came to the aid of the sector and, in early 2001 Plastiblow started to produce electric compact blow-moulding machines that were surprisingly high performance.

The models we offer are characterized by the quality of the applied technical solutions, some covered by patents, in single or double station, monolayer or multilayer coextrusion, with traditional extruders or forced feed version, for the use of high molecular polyethylene in granules or powder.

As required by the various industrial sectors, all blow-molding models can be customized.

Our range of extrusion blow moulding machines adopt new technologies in electric drives in order to get intelligent integration into industrial processes.

PB22ES-PB22ED

Stroke: 500-1300 mm

Mould clamping force: 220 kN

PB26ES-PB26ED

Stroke: 500-1300 mm

Mould clamping force: 260 kN

PB30ES-PB30ED

Stroke: 700-1400 mm

Mould clamping force: 300 kN

PB35ES-PB35ED

Stroke: 700-1400 mm

Mould clamping force: 350 kN