- About us

- Company details

We are a glass machinery manufacturing company. The staff is highly skilled and assisted by expert professional engineers. Customer assistance is provided by competent technicians and office workers, also by telephone.

Angelo Schiatti?s work has established its reputation on its knowledge of working problems acquired in a decade of direct experience by the client?s side, on its technical-construction know-how and on product applications. These qualities enable the company to propose high levels of quality and reliability in responding to the needs of all glass works, whether for small, craftsman?s workshops or large industry. Quality materials and products are the primary defining feature of Schiatti machines.

Year of establishment:

1984

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2005

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of metal forming machinery and machine tools

Manufacture of other special-purpose machinery nec

- Contact Information

- Business Proposals

Company:

OFFICINA MECCANICA SCHIATTI ANGELO S.R.L.

Web site:

Address:

VIA ALLA PORADA 0188

City:

SEREGNO (MB)

Zip Code:

20831

Social media:

Tag:

No business proposals uploaded

- Map

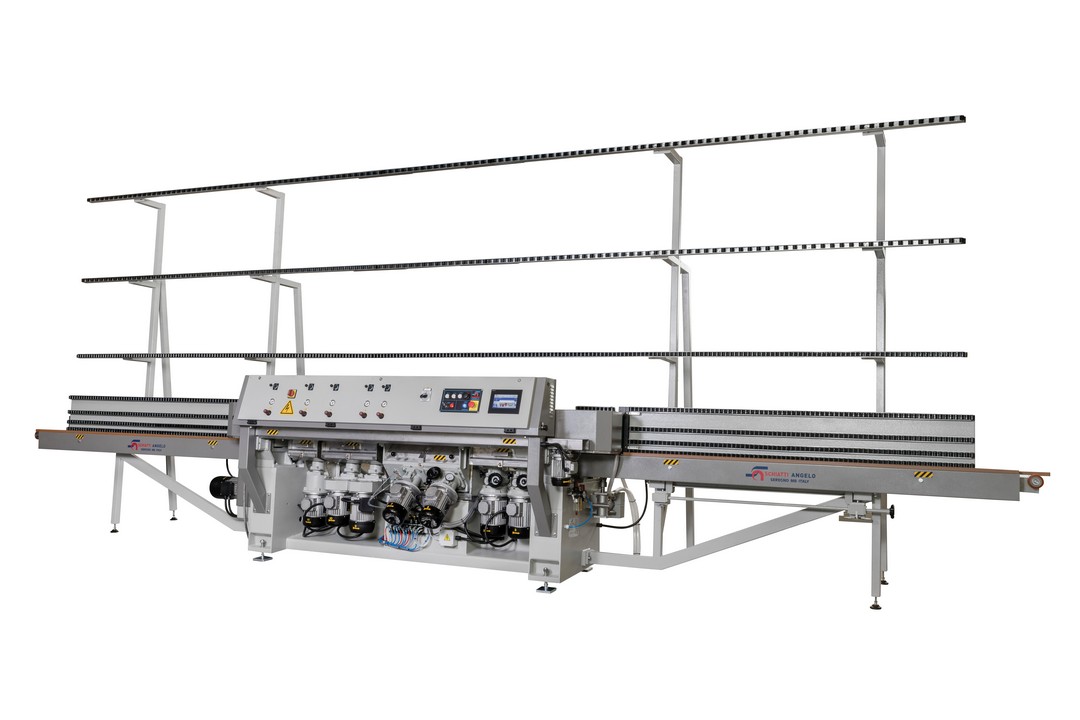

BFP20 complete line

DOUBLE EDGING MACHINE WITH CUP WHEELS FOR THE PROCESSING OF FLAT EDGE WITH ARRISSES FOR GLASS FROM 3 TO 20MM THICK.

Especially suitable to medium/big glass companies for the production of mirrors, shelves for furniture, laminated glass and stairs.

TFV2000

VERTICAL MILLING AND DRILLING MACHINES

for the execution of holes and notches on glass sheets from 3 to 19mm thick.

Especially suitable for medium/big glass companies for the production of mirrors, shelves for furniture, laminated glass, table tops, household appliances and doors.

FPS50M3

STRAIGHT EDGER WITH CUP WHEEL - GLASS THICKNESSES FROM 3 TO 55MM for the processing of flat edge and arris - variable angle from 0° to 45°- cerium oxide polishing on the edge and the arrisses.

Especially suitable to medium/big glass companies for the production of mirrors, shelves for furniture, laminated glasses, glass tables and stairs

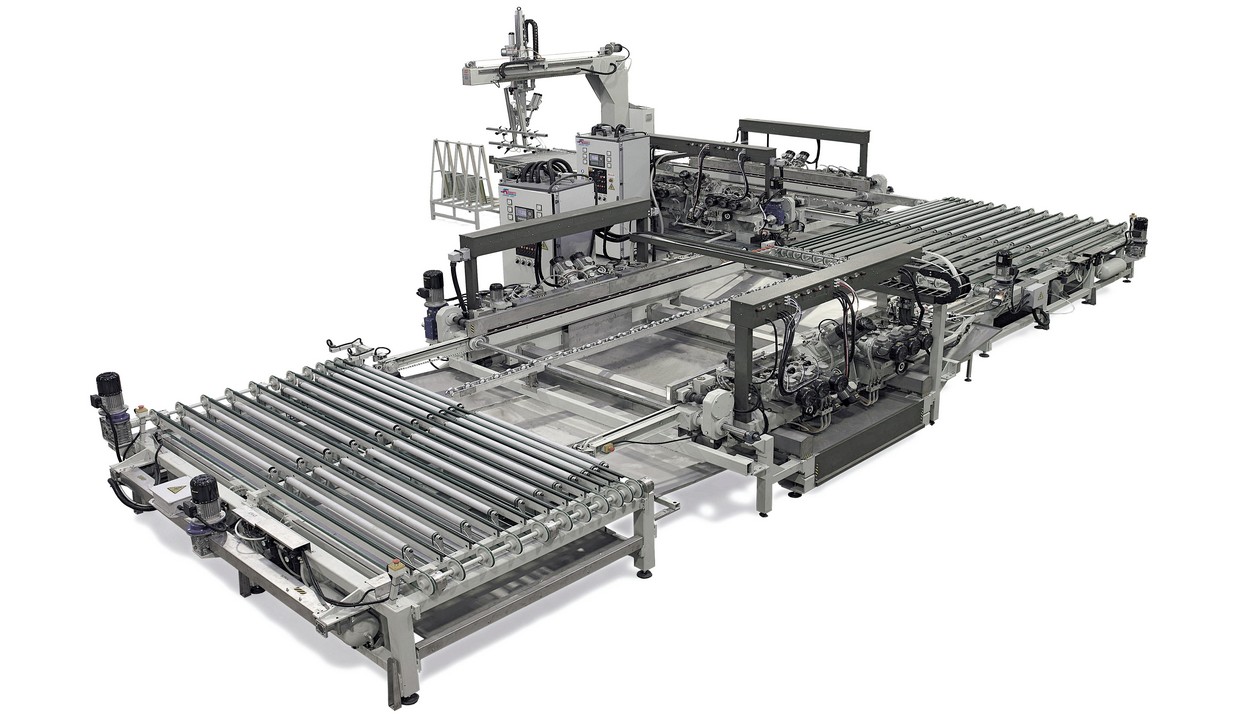

TURNOVER LINE

TURNOVER UNIT was designed and manufactured to connect two or more

edgers/bevellers in a line and has the function of rotating the glass-sheets through 90° .

The complete line, for the automatic processing of the all four sides of glass, is generally composed by 4 edgers/bevellers and 3 Turnover units. The

min. glass size is 300x300m, and the largest is 4.000x2.500mm , for thicknesses up to 10mm.TURNOVER UNIT allows to rotate glass-sheets through 90°.

Suitable for medium and large industries & glassworks.

Automation of glass rotation

FPS20RS

STRAIGHT EDGER WITH CUP WHEEL - GLASS THICKNESSES FROM 3 TO 30MMfor processing of the flat edge and arris - 45° mitres – cerium oxide polishing on the edge .

Essential and easy to use, the machines allow to obtain quality finishing. Especially suitable for small and medium glass companies for the production of mirrors, shelves for furniture, laminated glasses, glass tables and stairs.