- About us

- Company details

Our reality

An enviable know-how that, from design to mold making, from melting to finish, passes to the final control, providing each piece with an indispensable requirement: perfection.

The Company carries out its activity on an area of approx. 19,000 of which 9,000 are covered.

Three high capacity fusing furnaces allow perfect treatment of purified and degassed alloys with specific products purchased from the best companies in the industry. Only titanium aluminum alloys are used, provided by primary refiners that certify their quality. The alloy is immediately monitored by our specialized personnel with a geiger detector to detect any radioactivity and, subsequently, check the chemical components with the aid of a quantometer. Only after these tests the alloy is approved for use.

The die casting department has eleven machines with the following powers:

• 400 Tonn

• 500 Tonn

• 560 Tonn

• 600 Tonn

• 660 Tonn

• 1100 Tonn

• 1350 Tonn

• 1500 Tonn

• 2000 Tonn

• 2500 Tonn

Fully automated, computer-assisted electronic management with metal loader, piston and mold lubricant, thermoregulator, jet and shredder robots.

The steps and the production parameters of each detail are stored in the processor applied to each machine to ensure the perfect repeatability of the workpiece characteristics.

FONDERMETAL has a mold design engineering office and a tooling department that can handle any kind of problem in the management and maintenance of equipment.

Downstream of the foundry the finishing and mechanical machining department that allows us to perform the most requested finishing treatments.

Sophisticated tools supported by adequate software, SPC equipment and three-dimensional measuring machines are quality control. Capillary tests and strict tests, performed in-line and in the laboratory, supervise all the production process and allow FONDERMETAL S.p.A. the issuance of quality control cards and quality certifications (CPK and CMK) according to the most stringent international standards. The Company has been one of the first in its field to obtain quality certification since 1994.

Year of establishment:

1985

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2019

Export turnover:

From 5 to 15 million Euro

Activities:

Casting of metals

Casting of light metals

Manufacture of fabricated metal products, except machinery and equipment

Manufacture of other fabricated metal products nec

Manufacture of other parts and accessories for motor vehicles

- Videos

- Catalogue

No videos uploaded

No documents uploaded

- Contact Information

- Business Proposals

Company:

FONDERMETAL S.P.A. IN LIQUIDAZIONE

Web site:

Address:

VIA BEDESCO 37

City:

SOTTO IL MONTE SOTTO IL MONTE GIOVANNI XXIII (BG)

Zip Code:

24039

Tag:

No business proposals uploaded

- Map

automotive

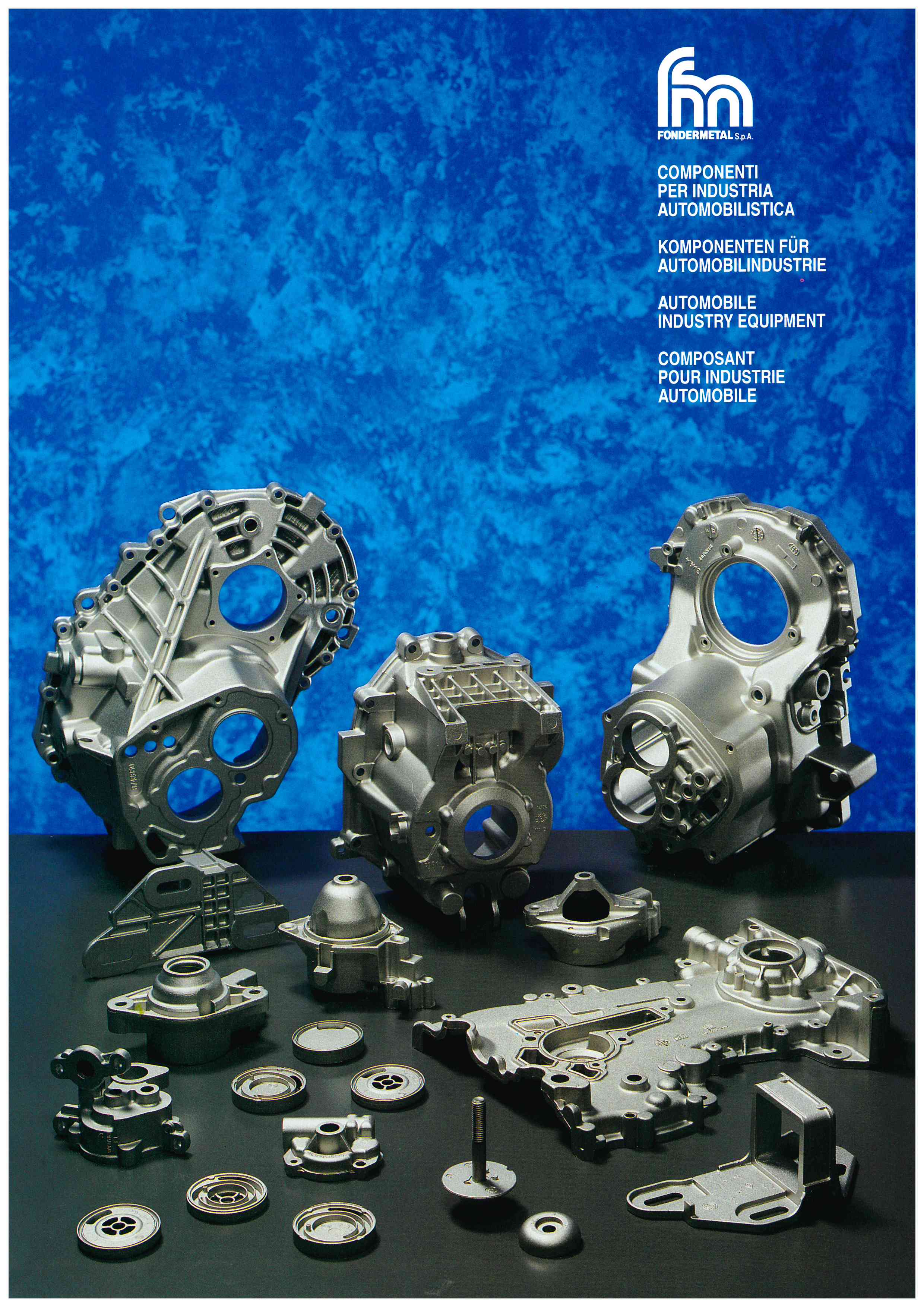

Automobile industry equipment

We cover a wide range of products such as clutch covers, gearbox casings, engine covers, carburetors, suction pipes, steering columns and so on, addressed to the automotive field and to the heavy means of transport. These parts require a high quality level, mainly constant along the time.

The design of the toolings is extremely important and for this reason we usually make use of the computerized simulation system of the injection from the first phase to the casting cooling one. Afterwards process and product statistical checks are carried out so that to grant that every slightest process deviation is immediately pointed out.

Web site

http://www.fondermetal.com/

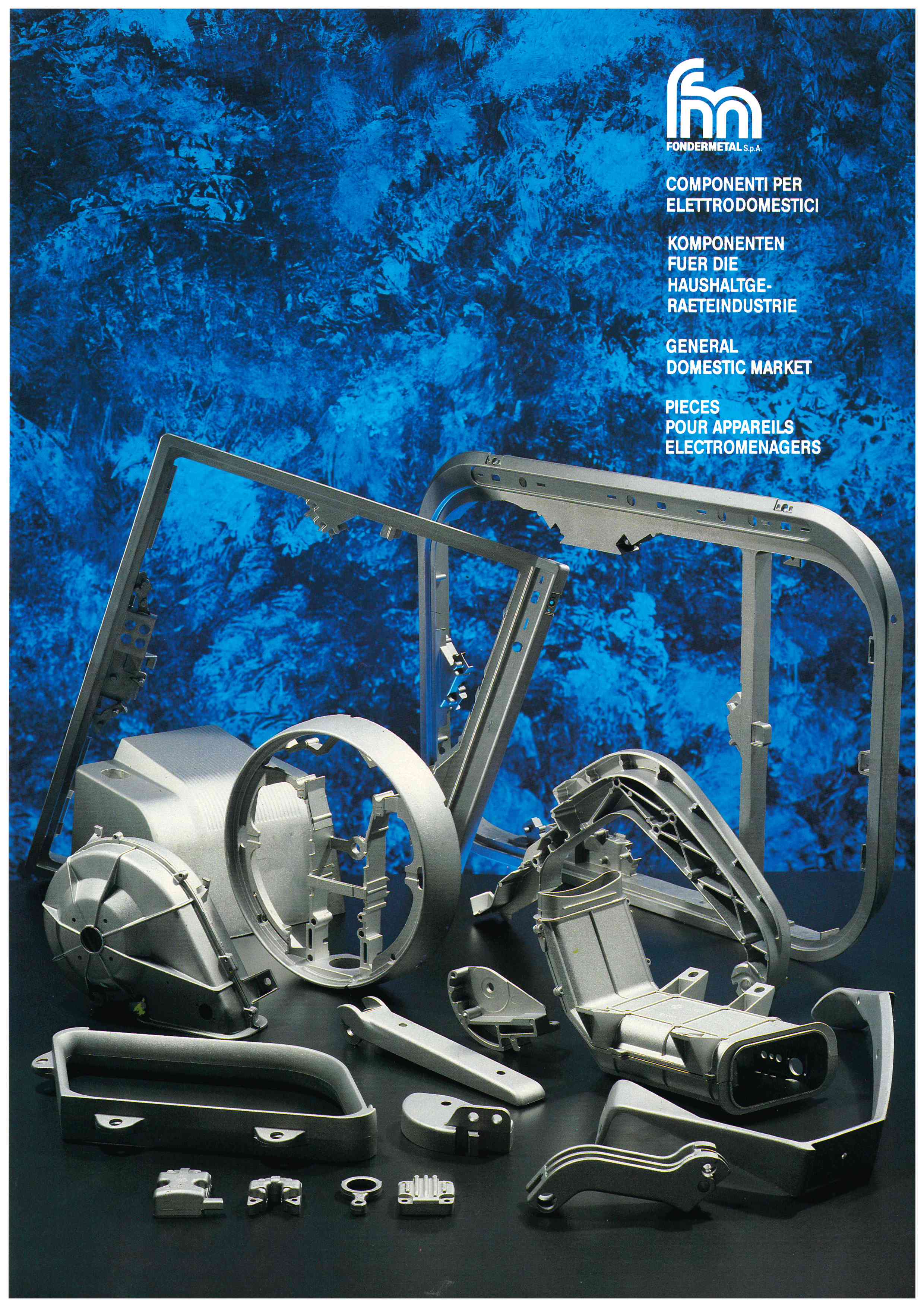

Domestic appliance field

Domestic appliance field

For this field we mainly produce components for refrigerator compressors, both for domestic and industrial uses. The difficulty of these products lies in the fact that very high quantities are normally requested to be supplied at very competitive prices. Consequently it is absolutely necessary to produce using multiple-cavity toolings with extremely quick production cycles, granting anyway the very high quality request.

We experienced several specific researches as far as die casting tools, the use of special kind of steels and the surface treatments of the die casting tools themselves are concerned. Strict and frequent dimensional checks are carried out and, basing on the involved quantities, they have been computer-based with the use of continuous 3D-scan equipments.

Web site

http://www.fondermetal.com/

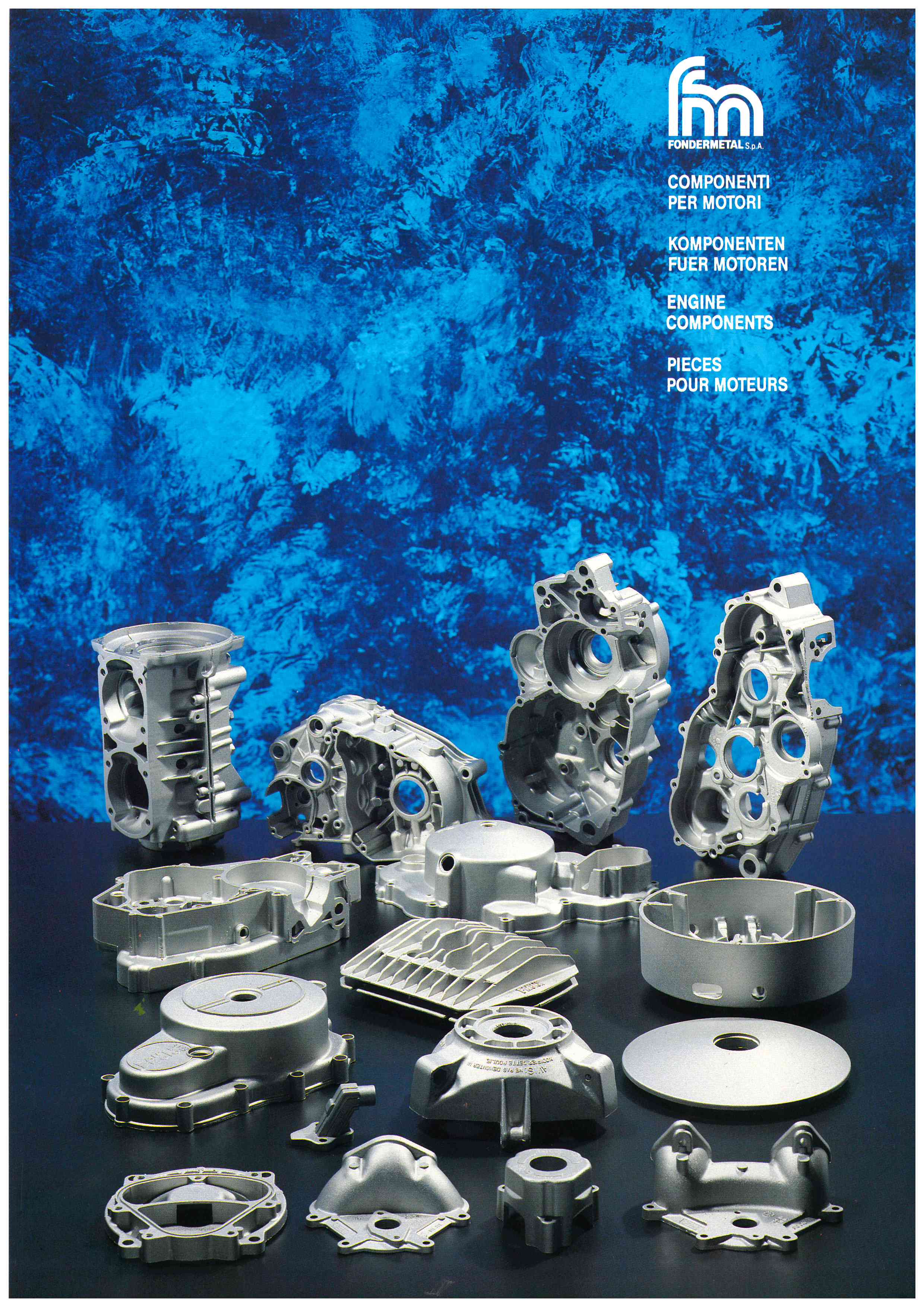

Engine components

Engine components

We produce a complete range of products including clutch covers, gearbox casings, engine covers, carburetors, intake tubes and many others for different industries such as the one for the motorcycles and the motors. These parts require a high quality level, mainly concerning the dimensional tolerances and the alloy treatments, to avoid difficulties in the machining and possible leakages.

Periodically we carry out destructive (hardness, liquid penetration, exhausting and maximum stress, tightness, and so on) and non-destructive tests (radiography and dimensional checks with continuous 3D-scan equipments).

Web site

http://www.fondermetal.com/

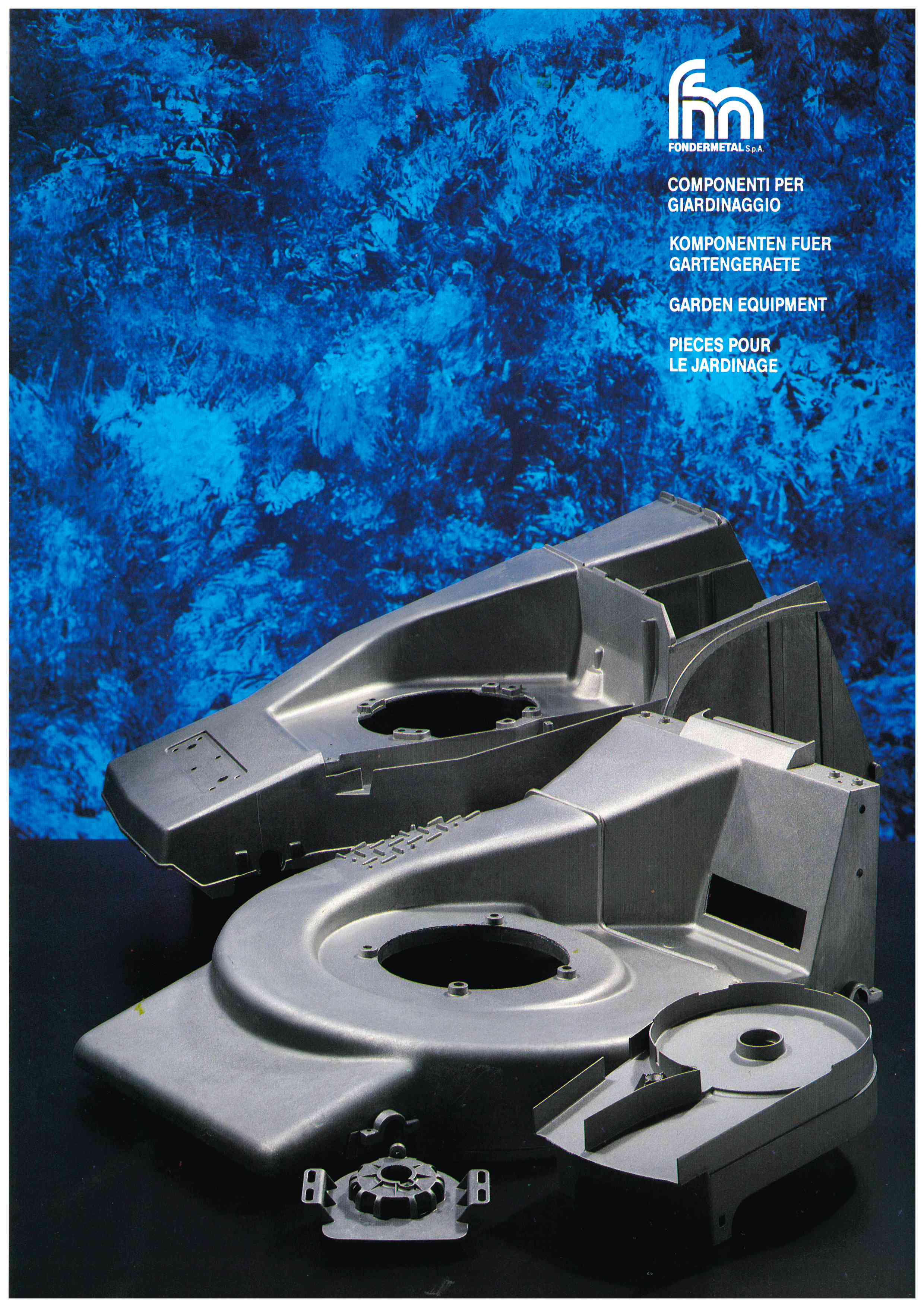

Garden Equipment

Garden Equipment

Our Company is specialized and particularly equipped for the production of gardening items from 5 to 15 kilos. These pars are produced on completely automated die casting machines from 1,200 to 2,500 tons which allow us to obtain in one automatic cycle completely machined parts which then need only to be deburred and sandblasted.

We have a wide range of Italian and foreign customers who appreciate our ability and cooperation in solving the different technical problems (tooling life, surface finishings, optimization of the injection, and so on) which are needed by these parts mainly due to their dimensions. We are also able to supply the parts with different levels of finishing, i.e. machined, sandblasted, painted.

Web site

http://www.fondermetal.com/

Lighting equipment

Lighting equipment

The peculiarity and the difficulty of these products lies in the thin wall thickness usually combined with the box shape. Only by properly projecting the toolings and using modern, computerized machines able to grant the repetitiveness of the parameters it is possible to produce parts with a perfect finishing level of the surface and compactness.

On the surface quality it often depends, for us and for our customers, the gaining of a market. The most important producers in this field are customers of ours since many years and they increase their business with us year after year. This means for us and for our customers to grant professionalism and quality of our production.

Web site

http://www.fondermetal.com/