- About us

- Company details

Torneria Fanti is a family-owned Italian manufacturer specializing in high-precision CNC turning and milling of custom metal components for critical industrial applications. Founded in Turin in 1938 and now operated by the third generation, we combine 87 years of manufacturing expertise with cutting-edge Industry 4.0 technology to deliver exceptional quality and service to B2B partners worldwide.

We manufacture custom-designed precision metal components including screws, pins, nuts, washers, bushings, shafts, and complex turned parts according to customer drawings and specifications. Our production capabilities cover bar diameters from ø4 mm to ø80 mm, serving industries where precision, traceability, and zero-defect quality are non-negotiable requirements.

Quality Certifications & Standards:

- IATF 16949:2016 – Automotive Quality Management System (since 2017)

- ISO 9001:2015 – Quality Management System (certified since 1998)

- ISO 14001:2015 – Environmental Management System (since 2017)

Technical Capabilities

Production Equipment:

- CNC fixed-head lathes (3-axis) with bar passage up to ø80 mm

- Swiss-type CNC lathes for precision turning from ø4 to ø32 mm

- CNC Machining Center for milling, drilling, and threading operations

- Automatic vertical warehouse (MODULA) for optimized logistics

Quality Control:

- Dedicated metrology room with climate-controlled environment

- Optical measuring machine MTL 500 EVO

- Complete Mitutoyo instrumentation (profilometer, hardness tester, roughness tester, altimeter)

- Certified measuring instruments with LAT center calibration

- Tolerance capability: ±0.01 mm

Materials Processed:

- Carbon and alloy steels, stainless steels (AISI 303, 304, 316, 420), aluminum alloys (2011, 6082, 7075), brass (CW614N, CW617N), and iron. All materials supplied with EN 10204 material certificates and full traceability.

We have fully embraced digital and environmental transformation with:

- MES (Manufacturing Execution System) implemented since 2016 for real-time production monitoring and complete traceability from raw material to delivery

- Automatic vertical warehouse for efficient inventory management and rapid order fulfillment

- Photovoltaic system (2023) for sustainable energy production

Beyond CNC machining, we provide finished components ready for assembly through our qualified network of external partners offering:

- Heat treatments (hardening, tempering, case hardening, nitriding)

- Surface treatments (zinc plating, nickel plating, chrome plating, anodizing, powder coating)

- Additional mechanical operations (grinding, thread rolling, surface finishing)

This integrated approach allows customers to receive fully finished parts, eliminating the complexity of managing multiple suppliers.

We serve both large OEMs and smaller specialized manufacturers by offering:

- Small batch production: from 100 pieces (ideal for prototyping, R&D, spare parts)

- Large volume series: up to 500,000+ pieces annually with consistent repeatability

- Fast response times: quotations within 48-72 hours

- Technical consultancy: design optimization, material selection, treatment recommendations

Our 2,500 m² manufacturing facility is located in Collegno (Turin metropolitan area), Northern Italy – a strategic industrial hub with excellent logistics connections to European markets.

Contact us to discuss how our precision manufacturing capabilities can support your supply chain requirements.

Year of establishment:

2006

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2019

Export turnover:

Less than 75.000 Euro

Activities:

Manufacture of fabricated metal products, except machinery and equipment

Manufacture of fasteners and screw machine products

- Contact Information

- Business Proposals

Company:

TORNERIA FANTI R. S.R.L.

Web site:

Address:

VIA SPAGNA 2

City:

COLLEGNO (TO)

Zip Code:

10093

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

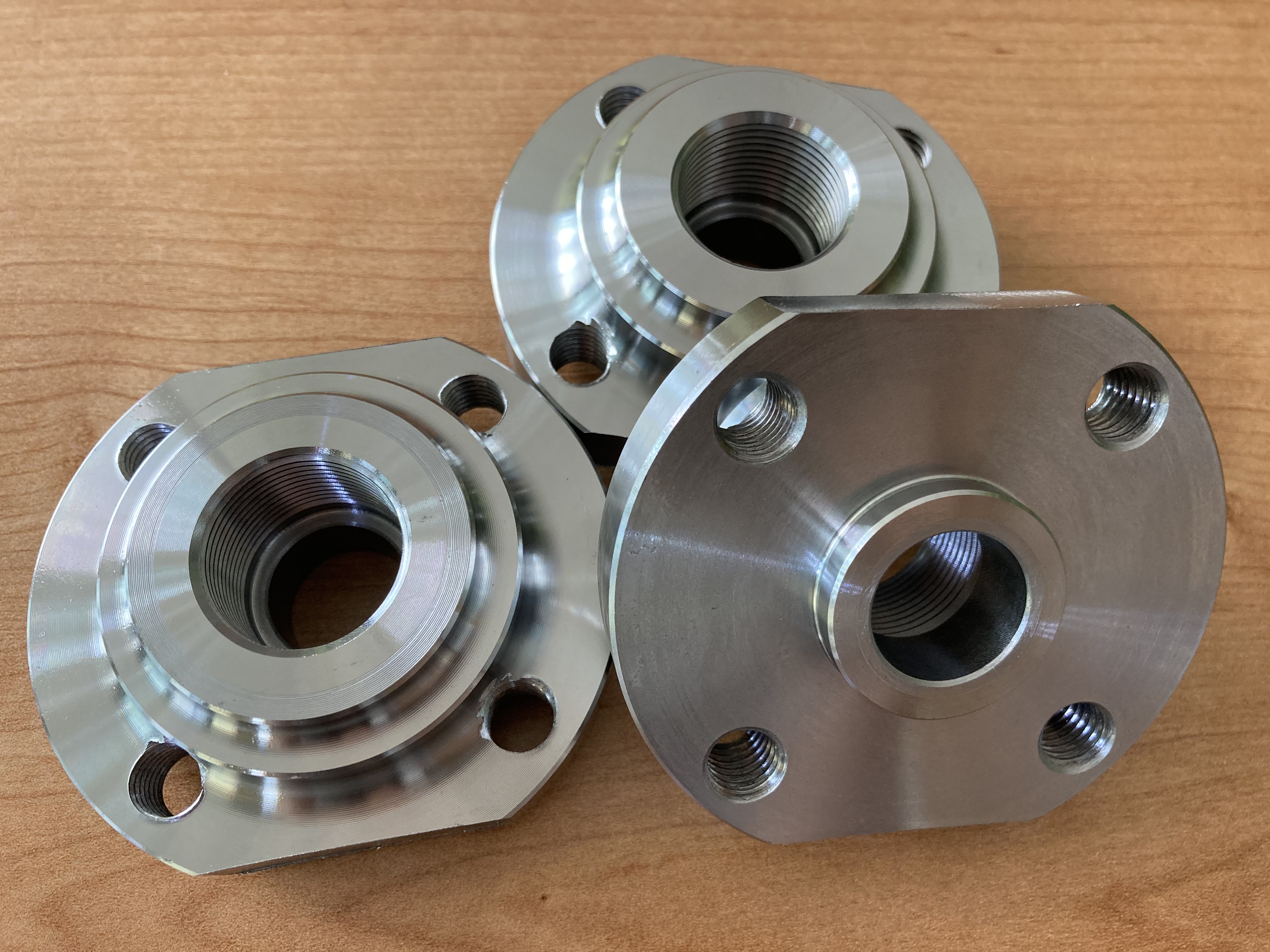

High-Precision CNC Turned Components – Custom Manufacturing to Customer Specifications

We manufacture a comprehensive range of precision-turned components including:

- Standard fasteners: custom screws, bolts, nuts, washers, threaded rods

- Mechanical components: pins, shafts, bushings, sleeves, spacers, collars

- Hydraulic parts: pistons, valve bodies, connectors, cylindrical components

- Complex turned parts: multi-diameter components, components with internal/external features, assemblies requiring secondary operations

All components are manufactured from bar stock with diameters ranging from ø4 mm to ø80 mm and lengths up to 300 mm, with the capability to achieve tolerances of ±0.01 mm and surface finishes as specified.

We process all industrial metallic materials including:

- Steels: carbon steels, alloy steels, tool steels, free-cutting steels

- Stainless steels: AISI 303, 304, 316, 316L, 420, 440C

- Aluminum alloys: 2011, 6061, 6082, 7075

- Brass: CW614N (MS58), CW617N, and special brass alloys

- Other materials: upon request and technical feasibility

Every material is supplied with EN 10204 Type 3.1 material certificates documenting chemical composition, mechanical properties, and traceability to melt number, ensuring complete documentation for critical applications and regulatory compliance.

Surface Treatments (via qualified external partners):

- Heat treatments: hardening, tempering, case hardening, nitriding, carbonitriding

- Galvanic treatments: zinc plating (white, yellow, black), nickel plating, chrome plating

- Surface finishing: anodizing (aluminum), powder coating, passivation

- Mechanical finishing: grinding, thread rolling, polishing, deburring

Every component is produced under our IATF 16949:2016 quality management system, which guarantees:

- Process control: Statistical Process Control (SPC) and First Article Inspection (FAI)

- Full traceability: from raw material batch through production to delivery via MES system

- Dimensional inspection: 100% critical dimensions verified, random sampling for secondary features

- Documentation package: dimensional reports, material certificates EN 10204, surface treatment certificates, test reports, certificates of conformity

Our dedicated metrology room features calibrated Mitutoyo instrumentation, optical measuring systems, and certified measuring equipment ensuring accuracy and reliability of all measurements. We maintain audit trails for regulatory compliance and customer-specific requirements.

Why Specify Torneria Fanti Components

✓ Automotive-grade quality for all sectors

✓ Complete traceability and documentation

✓ Flexibility from prototypes to high-volume series

✓ Turnkey service including surface treatments

✓ Made in Italy precision and reliability

✓ 87 years of manufacturing expertise

✓ Direct technical support from experienced engineers

We invite international buyers, OEM manufacturers, distributors, and procurement professionals to contact us with technical drawings and specifications for quotation. Our team responds promptly with competitive pricing, technical recommendations, and delivery schedules tailored to your requirements.

Web site

https://www.torneriafanti.it/