- About us

- Company details

Since 1978 in SAIP we have been designing and manufacturing plants and machines for the polyurethane industry. Our technological solutions are inspired by the goal of innovation, the value of sustainability and the highest quality standards.

We consider the collaboration with the customer fundamental in order to provide him with a truly personalized and strategic product in the growth of his business.

The Saip General Management is aware of the importance of the continuous improvement for the business development of the quality of its product and the service offered to customers and to this end has chosen to follow the principles of the reference standard UNI EN ISO 9001: 2015 and obtain certification. The first certification dates back to 2006.

SAIP products find application in various sectors, including: construction, professional and domestic refrigeration, furniture, pre-insulated pipes, oil & gas, automotive and various technical items.

SAIP technologies include: CONTITECH, complete lines for the continuous production of sandwich panels, DITECH, complete lines for the discontinuous production of sandwich panels, REFTECH, complete foaming plants for the production of refrigerated cabinets and doors, PIPETECH, special systems for the production of pre-insulated pipes and pipe joint insulation, SAIPTECH, customized solutions and turnkey projects for various polyurethane applications. Saip's offer also includes a wide range of high and low pressure dosing machines, machines for elastomers casting, mixing heads and spare parts.

SAIP is based in Inverigo, in the province of Como, a few kilometers from Milan. The headquarters, offices and production plant cover an area of over 10,000.00 square meters. where highly qualified and motivated personnel are employed. SAIP also makes use of a commercial network of agencies and affiliated companies that reaches all continents and that provides our customers with technical and commercial support.

SAIP is a POZZI INDUSTRIES company, an Italian group that brings together various companies that have polyurethane as their common denominator and that, thanks to the synergies between them, are able to offer cutting-edge integrated solutions.

Find out more at: www.saipequipment.it

Year of establishment:

1978

Number of employees:

FROM 50 TO 99 EMPLOYEES

Annual turnover:

Not available

Reference year of turnover:

2023

Export turnover:

Not available

Activities:

Manufacture of distilling or rectifying plant for petroleum refineries and chemical industries

Manufacture of plastics and rubber machinery

- Contact Information

- Business Proposals

Company:

SAIP S.U.R.L.

Web site:

Address:

VIA BRESSANELLA 13

City:

ROMANÒ DI INVERIGO INVERIGO (CO)

Zip Code:

22044

Social media:

Tag:

No business proposals uploaded

- Map

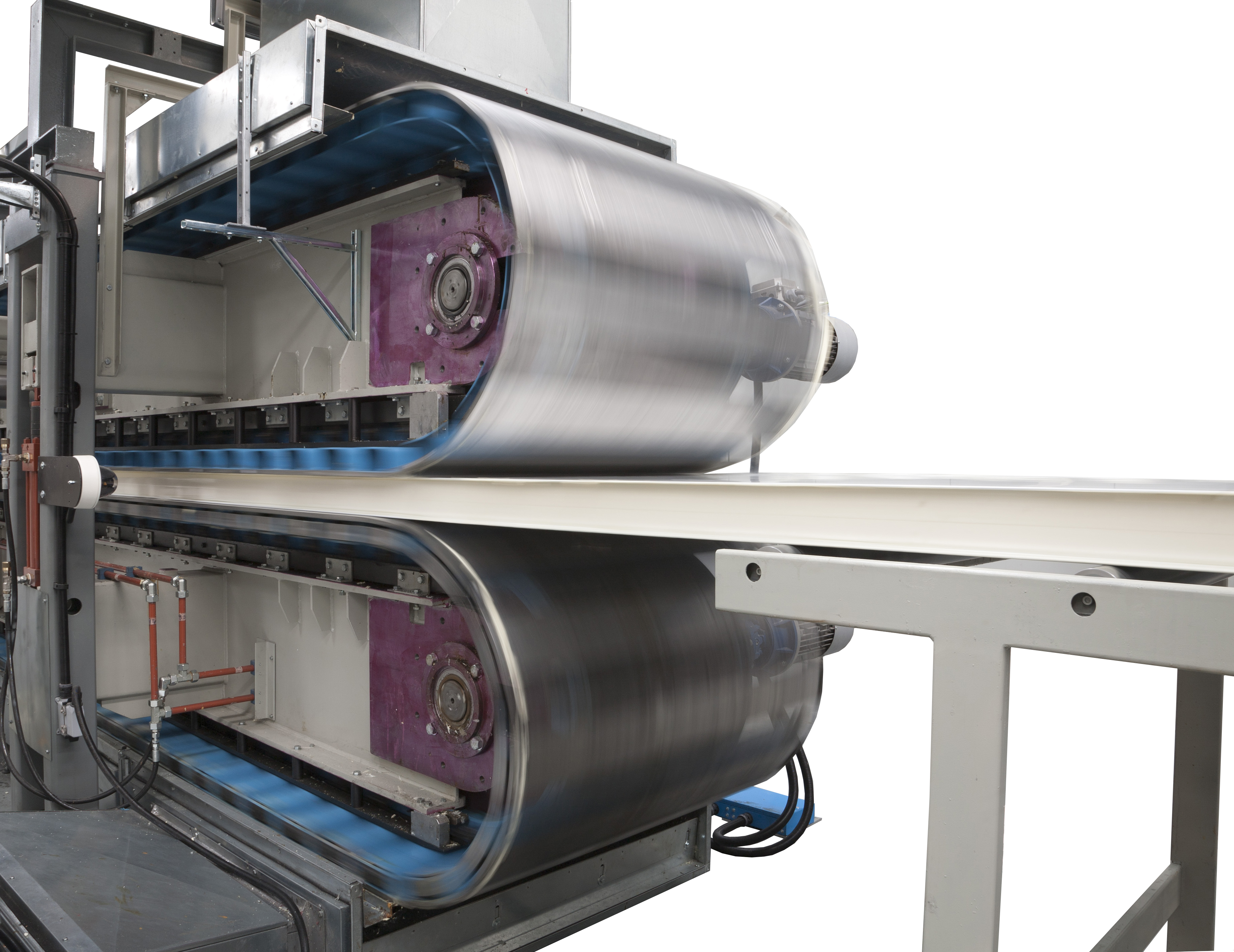

CONTITECH, complete lines for the production in continuous of sandwich panels

SAIP offers complete solutions both for the production of sandwich panels with rigid substrate, roofs and walls, with PUR, PIR and rock wool core, industrial and residential doors and gates, and for the production of sandwich panels with flexible substrate and PUR / PIR core, at high speed.

The continuous panel production method consists in dosing the reactive polyurethane mixture between two coatings that run in parallel on a conveyor belt. The reaction and hardening of the polyurethane mixture take place inside a moving press. The production speed varies according to the hardening time of the foam mixture, the thickness of the panels and the minimum cutting length.

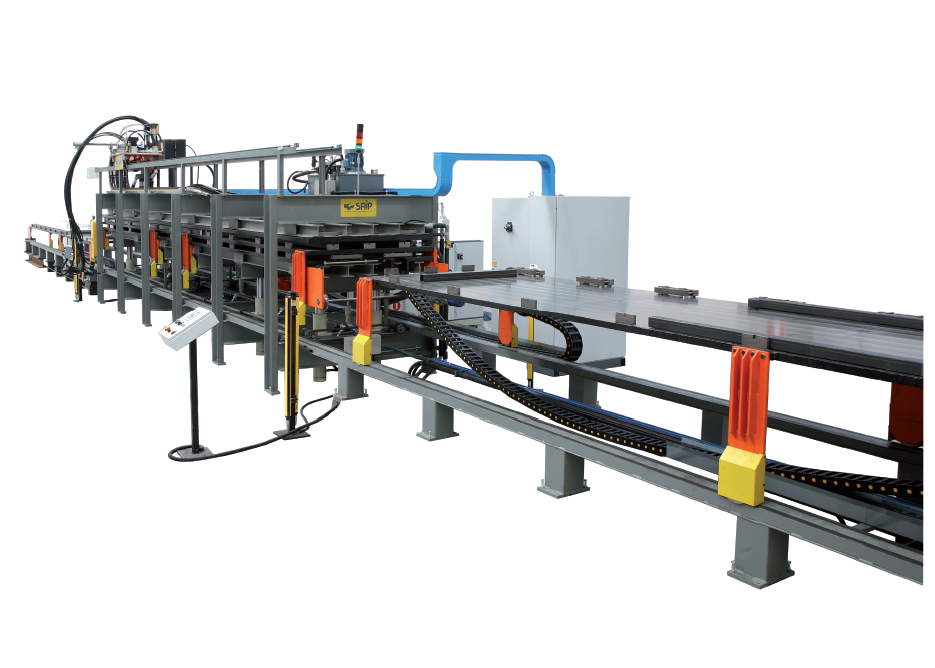

DITECH, complete lines for the production in discontinuous of sandwich panels

Complete lines for the production of sandwich panels with discontinuous method. The discontinuous process is used for the production of rigid surface panels, or flexible composite with a rigid polyurethane foam core, when a particular design and limited production volumes are required.

Various types of foam dosage solutions are available, according to customer requirements such as: the panel design, the production method and the efficiency required.

REFTECH, complete foaming solutions for professional and domestic refrigeration

Complete solutions for the insulation with polyurethane foam of all the equipment used in professional and domestic refrigeration.

Reftech technology is employed for the production of refrigerated cabinets and doors, display cabinets, cells, vending machines, ice machines, thermos, etc. Saip solutions include: foaming molds for cabinets and doors, single foaming masks and molds, handling systems, raw material storage systems

polyol/blowing agent mixing units, mixing and dosing machines, product design and industrialization and turnkey solutions.

PIPETECH, pre-insulated pipes production and pipe joint insulation

Complete solutions for the production of pre-insulated pipes (pipe-in-pipe) and for the protection, reinforcement and isolation of pipe joints in the production and lay down of pipe-lines segments.

International leaders have chosen SAIP as their partner. SAIP works alongside the customer and builds highly customized products, supplies focused consulting and provides with complete training operators, also on field. Its engineers are in fact authorized to work on off-shore platforms.

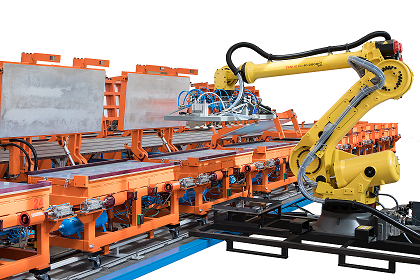

SAIPTECH, customised solutions and turn-key projects for various application of polyurethane

SAIPTECH is the technology serving ideas where customization is strategical.

Solutions include: multistation rotary table, oval carousel, stationary presses and mould press carriers, foaming automation with cartesian manipulators and robots, mould for presses, gasketing systems, etc.