- About us

- Company details

Comall International offers advanced technological solutions aimed at optimising manufacturing processes.

Comall International is a reference point in the design and production of pneumatic punching machines for aluminium profiles.

The company offers a wide range of extremely versatile and high performance punching machines, capable of satisfying the needs of suppliers and extrusion specialists all over the world.

Active collaboration with these entities has enabled Comall International to specialise in the punching machine sector and continue to offer innovative technological solutions.

Since 2017 Comall International has been the company within the Group dedicated to the manufacture and sale of systems for the assembly of thermally insulated profiles. Thanks to Fom Industrie’s consolidated and highly regarded thirty year industrial plan this new manufacturing adventure is coming into being.

A constant commitment to research and technological innovation, together with our assembly systems, made in Italy, allow maximisation of productivity while minimising working dimensions and manpower.

Year of establishment:

1988

Number of employees:

FROM 50 TO 99 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2001

Export turnover:

Not available

Activities:

Manufacture of doors and windows of wood

Machining of metals

Manufacture of locks and hinges

Manufacture of other fabricated metal products

Manufacture of machinery and equipment nec

Manufacture of metal forming machinery and machine tools

Manufacture of metal forming machinery and machine tools for metal work

Rental and operating of own or leased real estate nec

- Videos

- Catalogue

System for the production of thermally insulated profiles Using a single knurling machine the profile is produced in 2 successive phases; the unloading roller tables allow movement and unloading of the machined components. Line for medium-low production with 2 operators recommended.

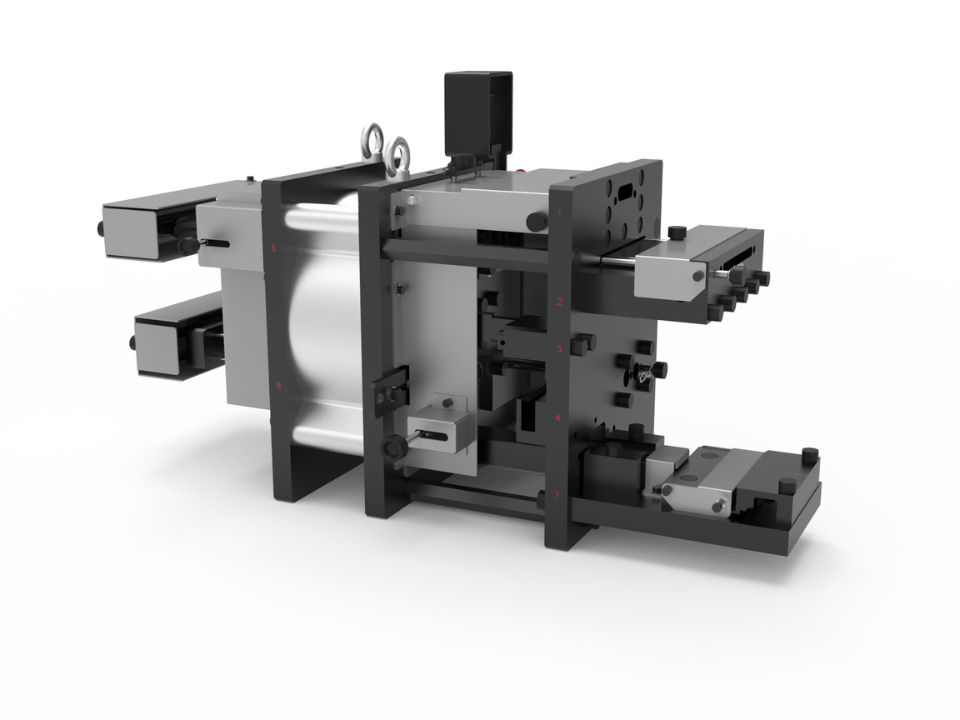

Comall Hybrid Punching Machine has been created to be ultra flexible and effective. With two different sides, one with fixed stations and one specific for housing station units, this punching machine can do many different workings in a limited space.

Thermal break profile assembly machine with controlled axis positioning (13 CNC axes).

- Contact Information

- Business Proposals

Company:

"COMALL INTERNATIONAL - S.R.L."

Address:

VIA SALIMBENE DA PARMA 4/C

City:

REGGIO EMILIA REGGIO NELL'EMILIA (RE)

Zip Code:

42124

Social media:

Tag:

No business proposals uploaded

- Map

Punching Machine

The quality of Comall projects is internationally unique: the company not only offers customised solutions but has always invested in the research and development of its products

This has enabled Comall to put onto the market the only horizontal drawer punch in the world, an exclusive patent for the company that has in effect revolutionised the market.

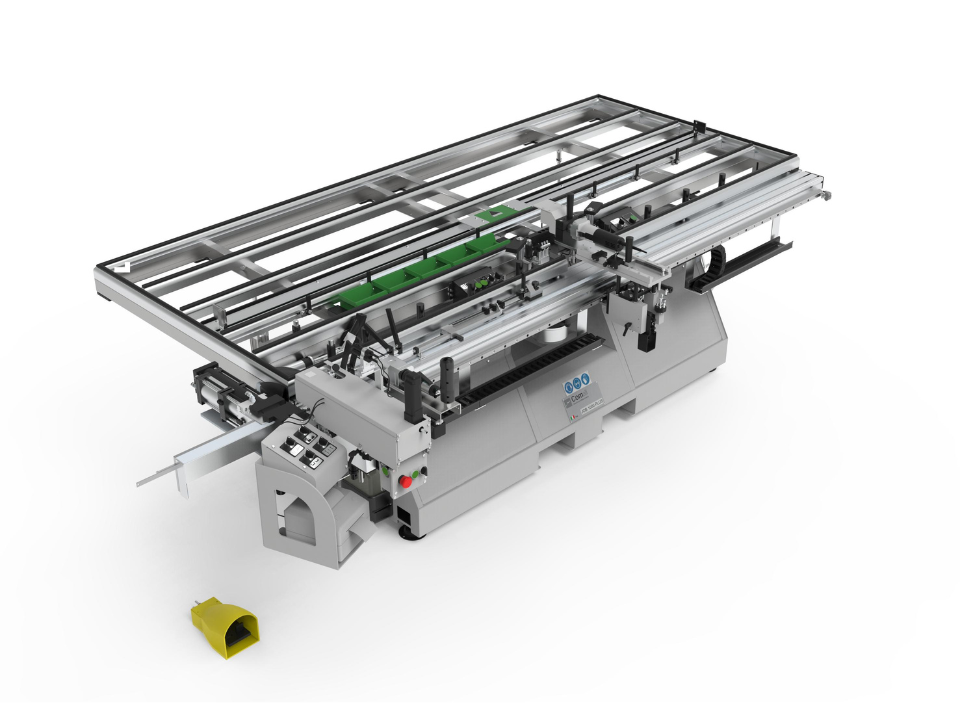

TAB 200 FM - Roll-forming Machine

Roll-forming machine for thermally insulated profiles with controlled positioning of the 13 NC axes.

Roll-forming machine for thermally insulated profiles with 13 independently positionable drive axes. Machine equipped with PC to set/store axis positioning values and store job data, TTK Integra SW to manage all the machines in the line.

TAB 100 M - Knurling Machine

Knurling machine with 6 driven axes and NC control.

Knurling machine with independent axis positioning and position storage.

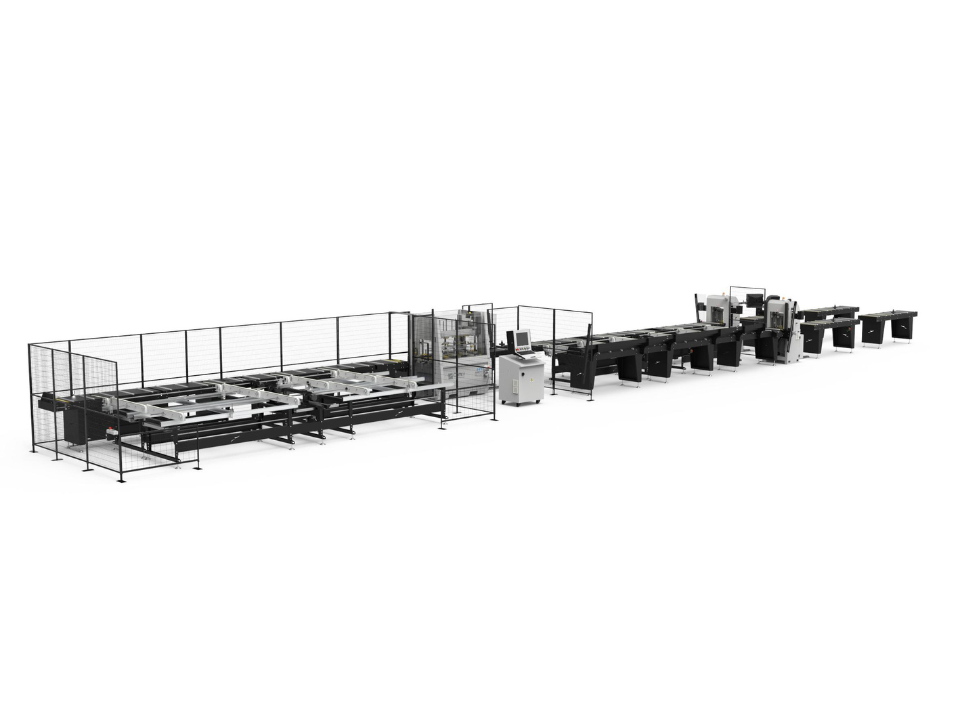

TTK 1000 - Thermal Break Line

System for the production of thermally insulated profiles.

The presence of a driven transfer between the two knurling machines and the unloading magazine downstream of the assembler allows manual movement of the profiles by the operators to be reduced to a minimum.

The proposed layout minimises the space required, while at the same time optimising the manpower resources needed for continuous operation of the system. Line for medium-high production with 3 operators recommended.

JOB 1000 PLUS - Multifunction Hardware Assembly Bench

Multi-function assembly bench.

Multi-function assembly bench for full assembly of hardware for PVC, wood-aluminium and aluminium window frames with perimeter hardware including 3 spindles drilling unit and frontal milling unit.