- About us

- Company details

ICT – International Consulting & Trading is a young and dynamic company founded in 2012 by the enthusiasm of two professionals of bearings industry, with more than 20 years of experience each within multinational companies like the Swedish SKF, the American NN and the Italian VLF.

With international experience in operations, engineering, plant management, sales and R&D, the founders have created in the years a network of partners, professionals and collaborators located between Europe and Asia and specialized in different areas and technologies of the high precision mechanics industry. ICT is in fact focused in providing value to the customers in this sector, with special eye to the bearings and bearing components industries.

The company offer includes:

• Strategical, Technical and Commercial Consultancy;

• Components for bearings industry & high precision mechanics;

• Grinding and Lapping technologies;

• Automatic Assembly and Control machinery;

• Cutting wheels;

• Castings;

• Special Bearings;

• Special projects (R&D, prototyping).

Main served markets are in Europe (Italy, France, Switzerland, Germany and Slovakia mostly), in Asia (India, China, Middle East and Vietnam) and in America (USA and Brazil).

Using the know-how and the background of the whole team, ICT supports the customers to get more and more success in their daily activities. This is possible through:

1. State-of-the-art technologies;

2. Simplification of all processes and new work methods;

3. Innovative IT and ERP systems;

4. Relationship based on long-term partnership;

5. Coherence with our company’s values.

Our partners, our collaborators and our suppliers are integer part of ICT, an uncommensurable value that we take extreme care of. We help each other to grow, learning every day something new that will become part of the company goodwill and will be soon transformed into customer value when we are less expecting it. It is like to have both the strengthes of a large multi-cultural company with thousand of employees in multiple worldwide locations and, at the same time, the flexibility of a man-sized consulting company capable to offer customized solutions and special care.

Customers are our precious value: whatever may happen, they shall “enrich” bot hour knowledge and our vision of the world. We never think of working with them in short term perspective, we are focused to show our capabilities in honest and professional way: we are aware that they shall be able to recognize such type of approach of ours and shall award it with more and more opportunities in the long term perspective. We genuinely feel to be important actors contributing to the results and to the achievements of all our customers.

Our values shape everything we do and every choice we make on behalf of the company!

Company values are:

• Openness and Integrity

• Hands-on Job

• Networking with partners

• Long-term relationship with customers

Year of establishment:

2012

Number of employees:

0

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2018

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of fabricated metal products, except machinery and equipment

Wholesale trade

Activities of head offices and management consultancy

Activities of head offices

Business and other management consultancy activities nec

Other professional, scientific and technical activities

Office administrative and support activities

- Contact Information

- Business Proposals

Company:

ICT DI PANACCIONE GIUSEPPE ED AGHEMO OSVALDO S.N.C.

Address:

VIA DEI MARTIRI DEL XXI 110 BIS

City:

PINEROLO (TO)

Zip Code:

10064

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Steel balls bearings

ICT offers steel balls in quality grades from G3 to G40, including the special Super-Premium grade designed for applications with high silence requirements. The chrome steel balls are made with clean 100Cr6 steel (i.e. without metallic and not metallic inclusions) produced only by well known Japanese, Korean and French steel mills. This is a guarantee of excellent resistance of balls to fatigue and wear, in such a way to avoid dangerous phenomena of balls spalling that might result into the same failure mode also on rings grooves. Balls are offered mostly in the dimensional range from 0.4 mm up to 200 mm of diameter (indeed for some materials it is possible to reach diameters up to 800 mm). Materials are all the possible imaginable: just get in touch with us at info@consulting-trading.com or through the contact form of the web site page (www.consulting-trading.com) to confirm the availability and get the quote. Chrome Steel Balls 100Cr6, i.e. the chrome steel used for bearings application, is the most widely used material for balls and is also known as 52100 or SUJ2 steel. The steel sources that ICT uses guarantee very fine-grain martensitic microstructure, which allows high hardness and exceptional wear and fatigue resistance properties. Our chrome steel balls are widely used worldwide in various applications, from bearings to ball screws, from constant velocity joints to check valves, from automotive steering to seating systems, just to mention few. The presence of our logo NHB Inside on these final applications is always a guarantee of superior quality of the finished assembled product. Through our partner we produce more than 4 billions a year of chrome steel balls. This allows the flexibility of a wide offer of high quality balls, served worldwide with just-in-time policy. Quality range includes the very special Super Premium specification besides the best ISO 3290 grades, i.e. G3, G5 and G10, for noise sensitive bearings. We offer G10 and G16 grades for HUB wheel bearings and G20, G24 and G28 for constant velocity joints. However we can support our customers to chose the best fit products for their own needs. Just get in touch with us directly at info@consulting-trading.com. Stainless Steel Balls ICT offer of stainless steel balls cover multiple types of materials. AISI 304/302, AISI 316, AISI 420, AISI 430, AISI 440C. ICT offer of aluminum balls is mostly made of type 2017 aluminum, i.e. solution treated copper alloy with natural aging to T4 conditions. Indeed balls also in 6061 and 7075 alloys are available. Tungsten Carbid Balls High hardness and dimensional stability make tungsten carbide balls the preferred choice for precision hydraulic valves, high-load bearings, inertial navigation systems, ball screws, linear bearings in slideways, gauging and checking instruments and meters.

Spherical, cylindrical and taper rollers

As for balls in ball bearings also rollers allow the relative movement between the parts and adjust the load transmission in the proper way, i.e. radially for cylindrical rollers, radially and axially for taper rollers and along variable direction for spherical rollers. Steel is 100Cr6 steel, but also 100CrMn6 steel (for diameters larger than 40 mm) and case hardened steel (wherever application requires special resistance to fatigue and/or wear) are available. The profile of these rollers may be “micro” designed in order to optimize the load distribution on the tracks of bearing rings, minimize the friction and the starting torque, optimize the energy efficiency of the ¬ final application and maximize the overall bearing performances. ICT is capable to offer the whole dimensional range of steel rollers through partners who have high quality standards in their process and flexibility of short lead-times. Furthermore, through consignment stocks available in Europe, it is possible to supply customers with just-in-time policy. Rollers are offered by ICT mostly in the dimensional range from 4 mm up to 160 mm of diameter (indeed for needles and pins it is possible to offer also smaller diameters, from 0.8 mm). Besides 100Cr6 steel and Chrome Manganese steel (for rollers larger than 40 mm of diameter), it’s possible to order also plenty of other materials: all stainless steels, many types of plastics, ceramics and many others. For all ZB and logarithmic profiles are available. • Cylindrical Rollers • Taper rollers • Spherical rollers • Needles • Ceramic rollers ICT cylindrical rollers are available both with pro¬ le TR and ZB, sorted in groups of 1 micron each or packed by plastic tube-packaging concept, keeping exactly the same production sequence as from the last lapping operation Spherical rollers of ICT ranges in the diameters from 8 to 160 mm and in lengthes from 8 to 160 mm, with radius end face that are included between a minimum of 44 up to a max of 1800 mm. Also in this case the most common type of steel is bearings chrome steel, 100 Cr6. However, for dimensions larger than 40 mm the chrome Mn steel is used in order to enhance the temprability properties of the material and to guarantee an uniform microstructure in the whole section of rollers (from surface to core). Chrome Steel Taper Rollers Taper rollers of ICT ranges in the diameters from 5 to 160 mm and in lengthes from 6 to 280 mm, with radius end face that are included between a minimum of 44 up to a max of 1800 mm. Most of these rollers are custom designed for each customer, satisfying very high standards of precision. is allows the taper rollers to facilitate smooth rotation of bearings, to reduce starting torque and to contribute to make longer the life of end products. Among the ¬ final applications, let’s here recall the automotive (e.g. suspension hubs, engines, transmission, etc.) and industrial machinery components (e.g. speed reducers, motors, cam followers).

Cages

Inside any bearing, cages have the purpose to keep the rolling elements at an appropriate distance from each other and to prevent direct contact between neighbouring rolling elements, in order to keep friction and thus heat generation at a minimum. Furthermore, through the cage, a proper load distribution is reached in the bearing, assuring quite and uniform running. However cages are mechanically stressed by frictional, strain and inertia forces and may also be subjected to the chemical action of certain lubricants, lubricant additives, solvents or coolants. Therefore the design and material are of paramount importance for the performance of the cage as well as for the operational reliability of the bearing itself. ICT can offer various cage types and designs of different materials for the different bearing types. Pressed cages are produced starting from steel sheet (in some case also from brass sheet) and pressing it in high precision presses, with very special tooling. ICT can offer ribbon-type brass or steel cages, riveted steel cages, snap type brass or steel cage and window-type steel cages. They have the advantage of lower weight and more space inside the bearing, that is an important point to facilitate the entrance of lubricant into the bearing itself. ICT offers also solid cages made from brass, steel, light alloy, polymer or fabric reinforced phenolic resin. Types are huge: two-pieces machined riveted cage, two-pieces machined cage with integral rivets, one-piece machined window-type cage, double pronged machined cage, injection moulded polymer window-type cage, injection moulded polymer snap-type cage and one-piece machined cage of fabric reinforced phenolic resin. They generally allow higher speeds than pressed cages and are necessary when conditions of high acceleration are important in application. ICT solid polymer cages represent a perfect combination of strength and elasticity, ideal in many conditions. Furthermore ICT can provide steel pin-type cages, used with pierced rollers, typically in large-sized roller bearings. These cages have relative low weight and enable a large number of rollers being incorporated. ICT can also offer PEEK cages and other high-tech plastic materials cage. Speci¬fically PEEK is an excellent material to guarantee low friction, high flexibility, wide temperature and possibility to manufacture even complex designs.

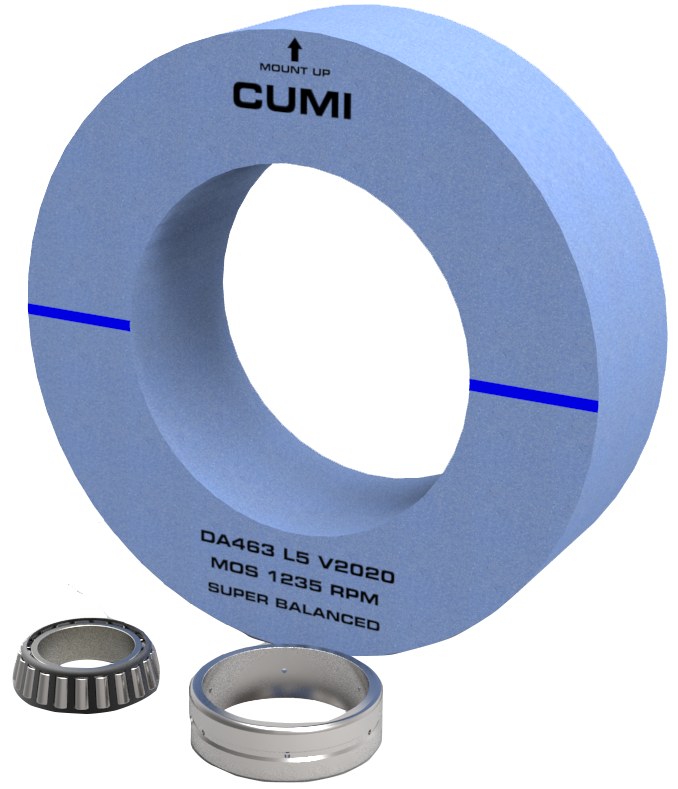

Grinding Wheels

For the rings external and internal grinding we have a complete range of wheels and abrasives to offer, suitable for full range of grinding machines available on the market and for all types of grinding (plunge, infeed and centreless). In this segment ICT can offer best in class solutions that have no comparison in the market in terms of wheels durability and productivity. Through our R&D center in Chennai (India) we are in condition to suggest the correct wheels and the customized solution to cover all your technical parameters. Our vitri¬fied wheels are available in a full range of abrasive: in aluminium Oxide AA, 12A and also in RA and RAA (pink aluminium oxide) designed to keep all types of profile for very long time; in monocrystalline sharp aluminium oxide 53-55A for high performance applications; in ceramic abrasive MCA-CUMISA for superior expectations. ICT regulating wheels (rubber wheels) are without comparison in the market, thanks to the long terms experience of our business partner in making them. The calendaring process enables excellent control in size and ¬ finish of components being ground. Special features assured by these wheels are a longer wheel life, a lesser dressing frequency, a superior form retention and an excellent surface ¬ finish. ICT covers the full range of dimensions for these rubber wheels. ICT’s versatile range of bore grinding wheels is used for grinding a variety of components that require size generation, ¬fine surface ¬finish and fast stock removal. We also offer value added services like sulphur treatment for lubrication and cooler cutting action. These wheels are characterized by sharp aluminium oxide grains for excellent cutting action and by crystal bond for form holding (V500). For the bearing rollers grinding ICT can offer a complete range of wheels and abrasives, suitable for the whole range of machines and both for centreless grinding and plunge grinding. In this segment we have best in class solutions that have no comparison in the worldwide market. Our technicians in Chennai R&D center are in condition to suggest the correct wheels and the customized solution to cover all customer technical requirements. ICT vitrified wheels are available in a full range of abrasive: in aluminium oxide AA, 12A and also in RA and RAA (pink aluminium oxide) designed to maintain all types of pro¬files for very long time; in monocrystalline sharp aluminium oxide 53-55A for high performance; in ceramic abrasive MCA-CUMISA for superior results; in silicon carbide C and GC. For the end face grinding of taper, cylindrical and spherical rollers ICT has different solutions of resinoid F-Type wheels (designed for the complete range of double disc machines) and vitri¬fied cup wheels (for taper rollers end face grinders). With a very long experience in the ¬ field, we are in condition to suggest the optimal solution in base to the roller dimensions and to the face area to be ground. The everyday growth of the sector of gears give us a great challenge to study and to develop continuously better abrasives to match the requirements. Special designed sharp mono crystalline grain, high performance ceramic grain blended with friable grain and Kristal bond system enable us to o er the best generation and complete range of grinding wheels for gears. Our world class manufacturing set-up makes sure that all the varieties of gear grinding (like single rib, multi rib, bevel, etc.) are covered. Wheels are suitable for all machines types present in the market: Niles, Hafler, Maag, Gleason, Pfauter, Samputensili and Hofler are some of them for single rib grinding; Reishauer, Liebherr, Kapp, Gleason, Pfauter and Samputensili are some few others for multi rib grinding.

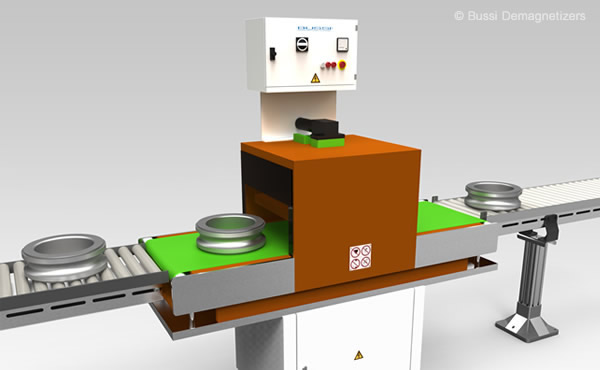

Control and assembly machines; Demagnetizers

Control and assembly machines ICT can develop all kind of assembly machines for the bearing industry, based on the speci¬fic needs and inputs of the customer. Examples of machines for assembling ball bearings are: • Greasing machines; • Rings and rolling elements pairing machines; • Caging machines, for different kinds of cage technology (cages with rivets, pronged cages, welded cages); • Seals and shields assembly machines, with post process flatness control; • Bearings preservation machines; • Packaging machine to automatically pack the bearings in a single package or in industrial boxes ICT can also provide the best solutions to your process needs to control (up to 100% or by sample) the products in manufacturing lines. Examples are the following: • Eddy Current control machines for all bearing components (internal and external rings, rolling elements – both balls and rollers); • Axial and radial control machines (both static and dynamic); • Visual and dimensional inspection machines (both of the individual rings and of the assembled bearing); • Automatic control devices for measurement of bearings noise and components weaviness; • Other measuring devices for parameters such as material hardness, starting torque, amount of grease, presence of burns and retempering, etc.. Moreover ICT is able to provide different demagnetization technologies depending on the specific application of the customer. Through a technology patented by our partner, we offer electronic pulse demagnetizers which guarantee very high performances. Demagnetizers Thanks to extensive experience in the demagnetization ¬ field, ICT is able to provide different demagnetization technologies according to the customer’s speci¬fic application. With a careful analysis of the project variables (such as the geometry and dimensions of the parts, the type of material, the transfer system and the production process, the productivity and the residual magnetism requirements) we can formulate proposals that are the most advantageous possible for the customer. Thanks to patented technology and on-going improvements over the years, we offer electronic impulse demagnetizers that ensure very high performances. In most cases the electronic demagnetizers realize a minimum residual magnetism and extremely low energy consumption (on average 150 W), which is as much as 20-30 times lower than the consumption of other demagnetizers. We furthermore propose demagnetizers with traditional technology that are suitable for other applications. Thanks to the special demagnetization coils construction, outstanding values are guaranteed in terms of residual magnetism, lower energy consumption and limited magnetic retention. Among different products and solutions, ICT can offer: • Demagnetizers in line installed in flexible conveyor chains; • Demagnetizers in line and off line with conveyor belt; • Demagnetizers installed in automated processes with parts handling by robot; • O line and manual demagnetizers for the demagnetization of single parts or parts placed in washing and transport containers; • Demagnetizers in line installed in rolling channels; • Contact angle measuring machine for ball bearings.