- About us

- Company details

Founded in 1965, Fastosi is a family owned and run metalworking, engineering and machine producing company. Based in Gerenzano (Lombardy, 20 minutes from Milan), for the past 20 years Fastosi has focused its export on innovative plastic extrusion lines. Fastosi has built complete lines of extrusion or machines able to improve already existing lines for the production of rods, hollow bars and sheets of variable size.

Below are some qualities of the materials which can be extruded by our machines:

• Polyamides (PA6, PA66, PA12, ,…)

• Polyoxymethylene (POM-C, POM-H)

• Polyethylenterephtalate (PET)

• Polycarbonate (PC)

• Polyvinylidenfluoride (PVDF)

• Polyetherimide (PEI)

• Polysulfone (PSU)

• Polyarylsulfones (PPSU)

• Polyphenylensulfides (PPS)

• Polyaryletherketone (PEEK)

• Polybutylterephthalate (PBT)

Additionally, we are able to develop specific projects by varying the size and structure of our production line. For example, in the standard lines we can insert accessories which can improve their production efficiency, such as aligned ovens, flow regulation valves, accumulators. We can also build multi-purpose production lines for the extrusion of round rods, sheets and products specifically designed for the medical field.

We also build single extrusion line components, such as:

- Extruders

- Dies

- Alligned ovens

- Presses

- Ovens

- Saws

- Pullers

- Auxiliary components: Transition block, Piston block, Melt accumulator, Brake, Stacker, Tipping table, Sheet calibrators, Profile calibrators, Lifting equipment, Die support trolley, Baskets, Thickness replacement arm, Recipe management software, Brakes

Everything our clients can think of, we can make.

Year of establishment:

1994

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2023

Export turnover:

From 2.5 to 5 million Euro

Activities:

Manufacture of structural metal products

Heat treatment of metals

Machining of metals

Manufacture of other various general-purpose machinery nec

Manufacture of plastics and rubber machinery

- Contact Information

- Business Proposals

Company:

"FASTOSI - S.R.L."

Address:

VIA FAGNANELLA 13

City:

GERENZANO (VA)

Zip Code:

21040

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Sheet extrusion line - 1200 mm width, with hydraulic press

All of our sheet lines are designed for the extrusion of sheets and can be fitted for the addition of press units for the quick-change of the production format.

They are also equipped with an aligned stabilization oven which is necessary for the automatic cut of extruded products.

Depending on the chosen die, it is possible to extrude sheets having thickness ranging from 6 mm to 150 mm seamlessly, accumulating the various frames.

In addition to the standard lines mentioned below, it is also possible to create the line by assembling the different types of extruders, pullers and by adding optional accessories such as saws, stackers etc … at the client’s discretion, up to a thickness of 300 mm.

This particular sheet line is equipped with a hydraulic press. Our presses, used on sheet extrusion lines, are necessary for the quick reconfiguration of the extrusion line. They allow changes to the thickness and width of the sheet during production in far less time compared to the ones achievable with the classic bolted die.

The “fast plate” presses are suppliable with thickness movement gear. This makes replacement possible even under heat, in order to additionally reduce the line’s set-up time.

Using hydraulic presses not only generates the forementioned benefits, it also positively impacts the quality of the extruded product. The difference between the lateral thickness and the central thickness is completely negligible owing to the machine’s remarkable stability. This allows to operate under higher extrusion pressures than the ones used on common sheet lines.

Rod extrusion line - 600 mm width

All of our rod lines are designed for the extrusion of rods and of hollow rods with variable diameter depending on the affixed die, with a yielding of 40/50 kg per hour. Teflon and lapped calibrators of sizes from 5 mm up to 300 mm ( from 0.25” up to 12” ) are available.

In addition to the mentioned standard lines, it is also possible to create the plant by assembling the different types of extruders and pullers and by adding optional accessories such as ovens, saws, tilt units etc … at the client’s discretion.

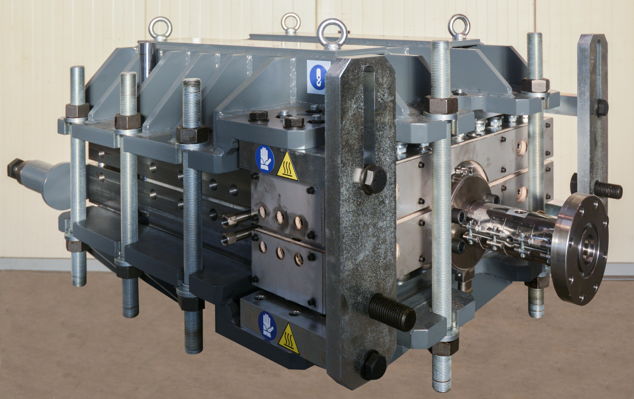

Sheet die

Fastosi dies are unique owing to their remarkable versatility in terms of the number and the size of the applicable calibrators.

The multi-area thermal regulation allows to maintain a constant and steady temperature of the material inside the die.

Regarding the sheet dies, we developed a stackable tools system which allows to seamlessly make sheets of any thickness.

Web site

https://www.fastosi.it/en/teste-2/

Multiple exit rod die

Fastosi dies are unique owing to their remarkable versatility in terms of the number and the size of the applicable calibrators.

The multi-area thermal regulation allows to maintain a constant and steady temperature of the material inside the die.

The rod dies, thanks to an innovative calibrator locking system, allow to considerably accelerate the production change.

We developed a standard system with eight calibration measurements, which allow us to maximize the number of rods depending on the line’s width. We can provide calibrators from 6 mm up to 300 mm.

Web site

https://www.fastosi.it/en/teste-2/

Single exit rod die

Fastosi dies are unique owing to their remarkable versatility in terms of the number and the size of the applicable calibrators.

The multi-area thermal regulation allows to maintain a constant and steady temperature of the material inside the die.

The rod dies, thanks to an innovative calibrator locking system, allow to considerably accelerate the production change.

Web site

https://www.fastosi.it/en/teste-2/