- About us

- Company details

Treccani Engineering have started activity in 2011 in Verona (Italy). From 2007 to 2011, Eng. Treccani collaborated with different companies designing new machines and manufacturing prototypes concerning various sectors of industrial automation, machine tools and general mechanics. During these years of work experience, several projects were developed for

different types of customers.

We aim to develop support activities to prop up customers in the realisation of new products and the optimisation of existing products. We can guarantee to the customer quality and reliability respecting the requested functionalities in the technical specifications defined following our experience.

We are experienced partners who translate customers’ ideas or needs into feasible designs and prototypes realised with competence and expertise.

We are able to produce batches of small series with the realization of the initial prototype and subsequent industrialization. The competence and in-depth experience that guide us make us the right partner for an all-round collaboration that develops from the idea to the finished product.

Year of establishment:

2012

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2023

Export turnover:

From 75.000 to 250.000 Euro

Activities:

Manufacture of other lifting and handling equipment

Engineering activities

- Contact Information

- Business Proposals

Company:

TRECCANI ENGINEERING S.R.L

Web site:

Address:

VIA GRACCO SPAZIANI 41

City:

VR VERONA (VR)

Zip Code:

37138

Social media:

Tag:

No business proposals uploaded

- Map

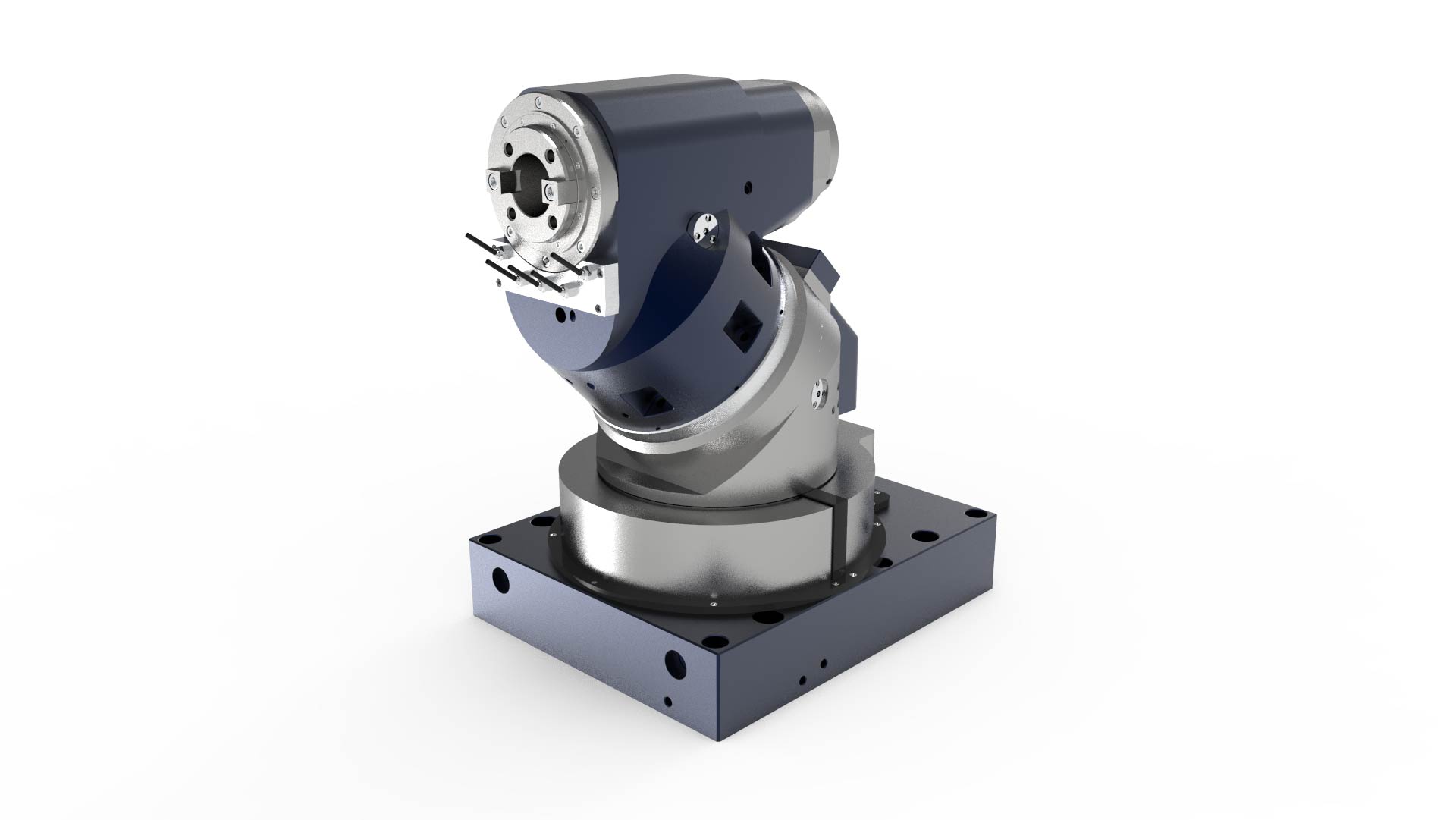

UNIVERSAL MILLING HEAD - automatic accessory for metalworking machine tools. Technical characteristics specified in the enclosed brochure.

Main technical mechanical characteristics:

- Main structures in cast iron;

- Bearings of axis with preloaded roller;

- Indexing position axis:

1. index 2,5° (1° optional) positioning

> driving system C axis with mechanical couplings direct with spindle of machine

> driving system A axis with mechanical couplings direct with spindle of machine

2. index 0.0001° positioning

> driving system C axis with mechanical couplings direct with spindle of machine

> driving system A axis with mechanical couplings direct with spindle of machine

- Direct measure of the angular position of the two axis for 0.0001° and index 1°

- Direct measure of the angular position only C axis for index 2,5°

- Limit switch on C and A axes for end stroke, zeroing, locking and unlocking

- Automatic clamping of the head on the face of the machine with reference pin and puller pin

- Inner feeding water through the spindle 20 bar 15 l/min;

- For head changing there is an anti-rotation device to keep the power take-off in position

- Interfacing with the customer machine is defined according to the type of fixing according to two possibilities:

a. manual with screws and reference pins

b. automatic with attachment beads and reference pins

Main technical hydraulic characteristics:

- Air of pressurization for the head inside and for the spindle flange.

- Grease lubrication for the movement transmission and of the spindle bearings.

- Hydraulic cooling oil system of the head.

- External feeding of water to the tool 10 bar 30 l/min;

- Electrical connectors for automatic changing heads or hole for the cables for manual changing heads;

- Liquid connectors STAUBLI for automatic changing heads or hole with seal for manual changing heads

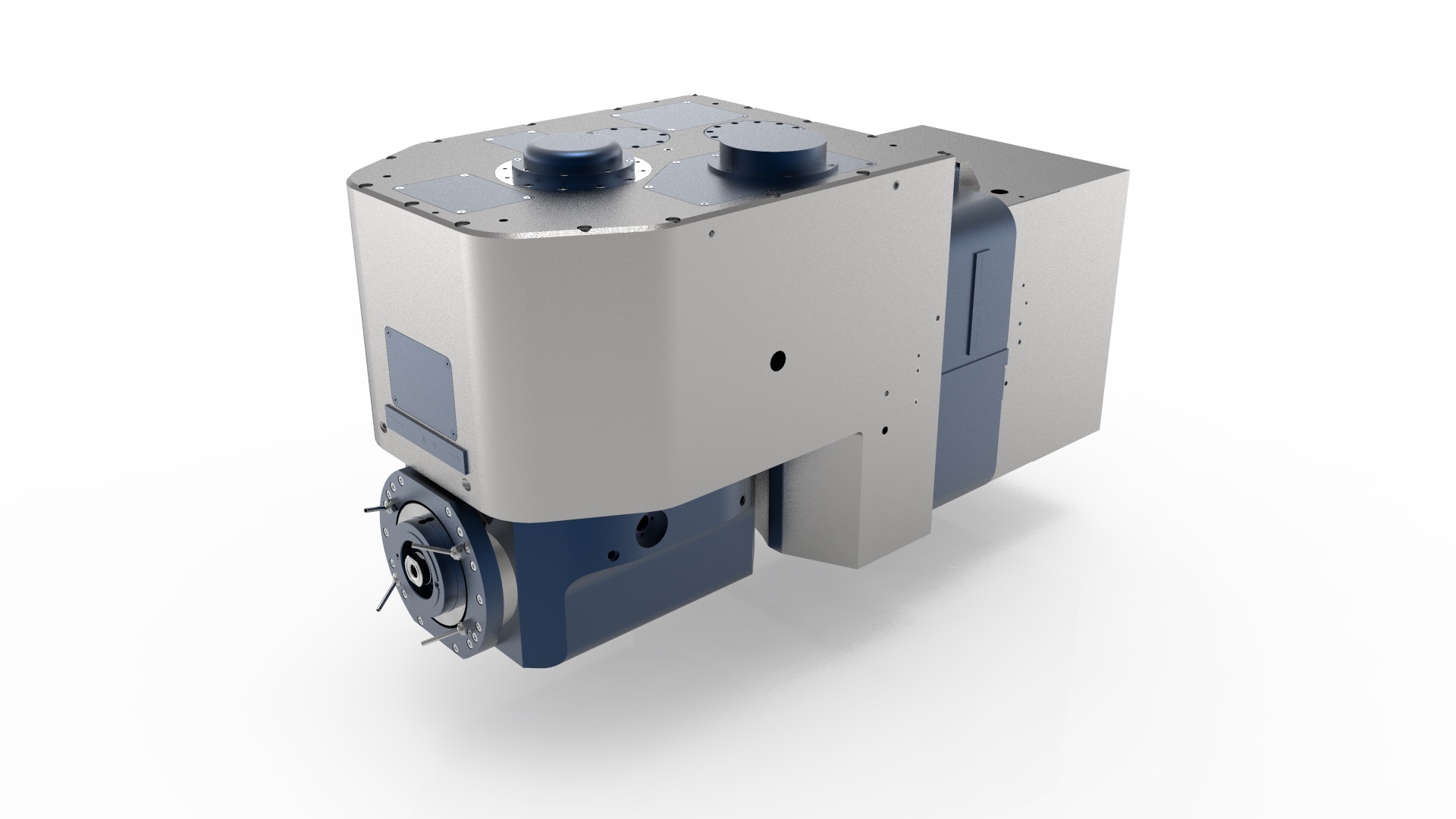

FORK MILLING HEAD - automatic accessory for metalworking machine tools. Technical characteristics specified in the enclosed brochure.

Main technical mechanical characteristics:

- Main structures in cast iron;

- Bearings of axis with preloaded roller;

- Indexing position axis:

1. continuous positioning

> driving system C axis with double pinion and wheel gear with recover mechanical or electrical backlash

> driving system A axis with double pinion and wheel gear with recover mechanical or electrical backlash

- Direct measure of the angular position for C and A axis for for continuous positioning and machining

- Limit switch on C and A axes for end stroke, zeroing, locking and unlocking

- Automatic clamping of the head on the face of the machine with reference pin and pull stud.

- Inner feeding water through the spindle 20 bar 15 l/min;

- For head changing there is an anti-rotation device to keep the power take-off in position

- Interfacing with the customer machine is defined according to the type of fixing according to two possibilities:

a. manual with screws and reference pins

b. automatic with attachment beads and reference pins

Main technical hydraulic characteristics:

- Air of pressurization for the head inside and for the spindle flange.

- Grease lubrication for the movement transmission and of the spindle bearings.

- Hydraulic cooling oil system of the head.

- External feeding of water to the tool 10 bar 30 l/min;

- Electrical connectors for automatic changing heads or hole for the cables for manual changing heads;

- Liquid connectors STAUBLI for automatic changing heads or hole with seal for manual changing heads

ORTHOGONAL MILLING HEAD - automatic accessory for metalworking machine tools. Technical characteristics specified in the enclosed brochure.

Main technical mechanical characteristics:

- Main structures in cast iron;

- Bearings of axis with preloaded roller;

- Indexing position axis:

1. index 2,5° (1° optional) positioning

> driving system C axis with mechanical couplings direct with spindle of machine

2. index 0.0001° positioning

> driving system A axis with SIEMENS motor (Typo 1FK2104) and commercial gearbox with accuracy to movement of all positions

- Direct measure of the angular position of the two axis for 0.0001° and index 1°

- Limit switch on C and A axes for end stroke, zeroing, locking and unlocking

- Automatic clamping of the head on the face of the machine with reference pin and puller pin.

- Inner feeding water through the spindle 20 bar 15 l/min;

- For head changing there is an anti-rotation device to keep the power take-off in position

- Interfacing with the customer machine is defined according to the type of fixing according to two possibilities:

a. manual with screws and reference pins

b. automatic with attachment beads and reference pins

Main technical hydraulic characteristics:

- Air of pressurization for the head inside and for the spindle flange.

- Grease lubrication for the movement transmission and of the spindle bearings.

- Hydraulic cooling oil system of the head.

- External feeding of water to the tool 10 bar 30 l/min;

- Electrical connectors for automatic changing heads or hole for the cables for manual changing heads;

- Liquid connectors STAUBLI for automatic changing heads or hole with seal for manual changing heads