- About us

- Company details

Since 1998 KAPA ENGINEERING respecting the environment, study and manufactures machinery for any kind of waste, treatment.

Prototyping and innovative using the most advanced modern technology, providing our customers with reliable equipment.

Headquartered in Italy provides the European and International market the most innovative global environmental systems.

Year of establishment:

2017

Number of employees:

SINGLE USER

Annual turnover:

between 250.000 and 500.000 Euro

Reference year of turnover:

2017

Export turnover:

0

Activities:

Manufacture of other various general-purpose machinery nec

Manufacture of other agricultural and forestry machinery

Manufacture of other special-purpose machinery

Manufacture of machinery for food, beverage and tobacco processing

Manufacture of all other various special-purpose machinery nec

Installation of other industrial machinery and equipment

- Contact Information

- Business Proposals

Company:

KAPA ENGINEERING SOCIETA' A RESPONSABILITA' LIMITATA SEMPLIFICATA

Address:

VIALE ORTLES 22/4

City:

MILANO (MI)

Zip Code:

20139

Social media:

Tag:

No business proposals uploaded

- Map

Physis dryers

Physis dryers and common rotary drum dryers are both used to remove moisture from materials in agricultural wastes or sludge, industrial sludge, woody biomass, anaerobic dewatering and more. However, there are some significant differences between the two types of dryers that might influence your choice between them. Here are some reasons why you might prefer a Physis dryer over a rotary drum dryer:

Energy efficiency: Physis dryers are designed to be more energy efficient as they use advanced technologies such as the use of an adjustable flow of hot air within the modules that can significantly reduce energy consumption compared to traditional methods.

Final product quality: Physis dryers tend to better preserve the quality of the final product. Because drying takes place at lower temperatures and in a more uniform manner thanks to the work of the augers and the hot air inside them, the colour and consistency of the dried materials can be maintained better than with rotary drum drying, which can generate excessive heat and, more importantly, alter the characteristics of the final product by producing the so-called caramelisation effect (especially for sludge of an agricultural nature such as olive pomace).

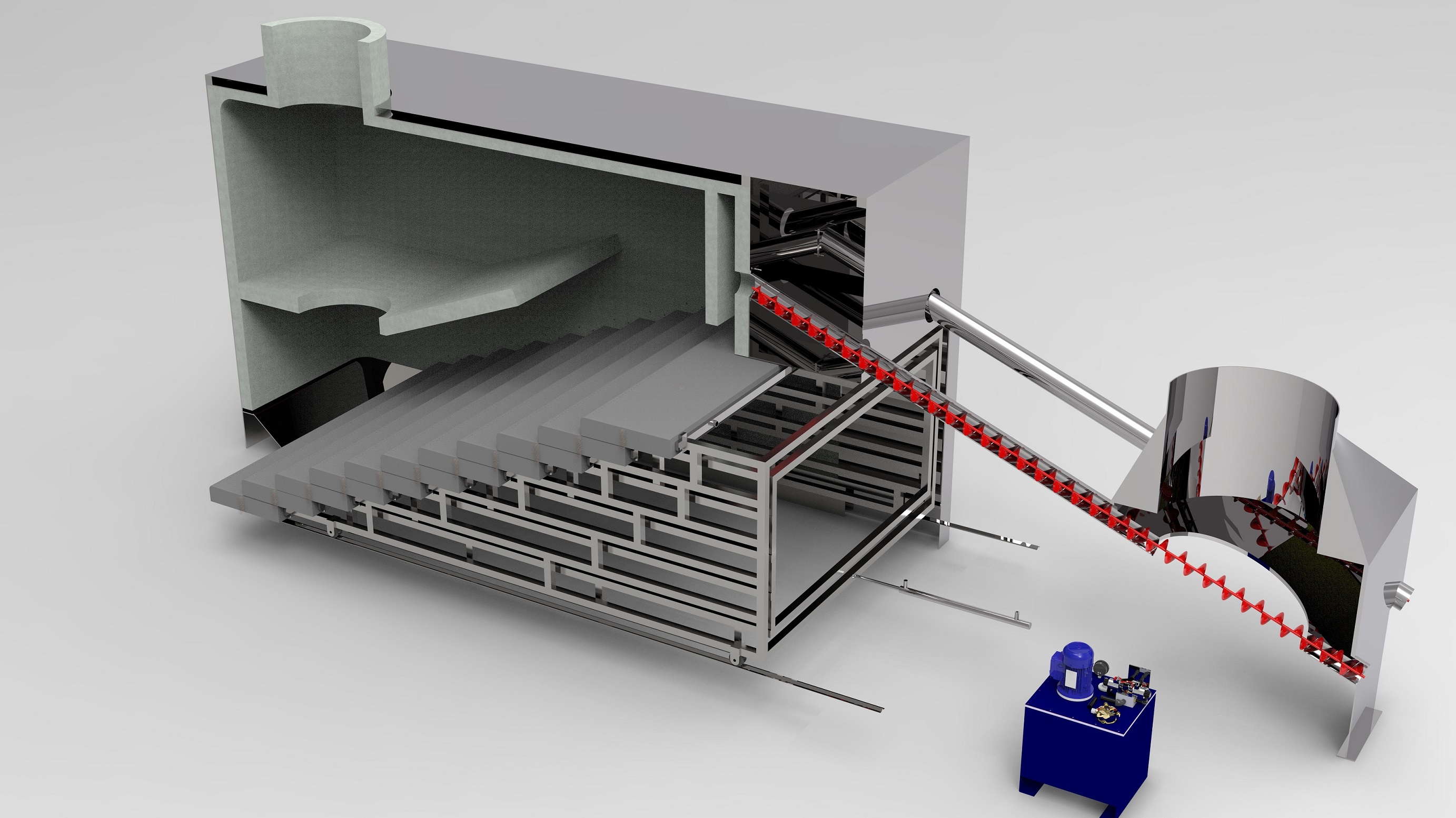

Biomass burner with moving grate

Moving grate burners are commonly used in industrial settings, district heating systems, and biomass power plants due to their ability to efficiently convert a wide range of biomass materials into thermal source while maintaining a steady and controlled combustion process. The key feature of this burner is its horizontally-oriented grate that continuously moves the biomass fuel through the combustion process. Fully automatic controlled and in compliance with the EU standards.

Hefaistus incinerator

We design and build tailored incinerators to meet our customers' specific needs, ensuring maximum efficiency and regulatory compliance. Energy Recovery Systems: Our incinerators are designed to recover thermal energy from burned waste, contributing to steam or electricity production. Eco-Friendly Solutions: We pay special attention to controlled gas emissions and management of residual ashes to reduce environmental impact. Technical Assistance: We offer maintenance, support, and training services to ensure the long-term proper functioning of our incinerators. Consulting and Design: We work alongside our customers from the initial phases, providing advice in plant design and waste management planning. Application Sectors: Our incinerators find application in a wide range of sectors, including:

Municipal and industrial solid waste management

Treatment of hazardous and medical waste

Disposal of food and agricultural waste