- About us

- Company details

Axtra: Italian Engineering for Bottling Excellence

Axtra designs and manufactures high-quality bottling systems, combining Italian innovation, precision, and reliability. With decades of experience in the beverage and packaging industry, we support our customers from the initial design phase to the full realization of linear or rotary bottling plants tailored to their specific production needs.

Our technical department carefully analyzes each client’s requirements to develop customized, efficient, and cost-effective solutions that ensure long-term operational optimization.

Axtra produces individual machines and complete monoblock systems for a wide range of functions, including:

- Container internal cleaning;

- Filling;

- Capping and capsuling;

- Labelling;

- Container inspection;

- Conveying systems.

Our flexible approach allows us to integrate new equipment into existing production lines or incorporate pre-existing machinery into our systems, ensuring seamless compatibility and optimal performance.

Axtra manages every stage of the process directly — from installation to operator training — guaranteeing smooth start-up and efficient operation. Our after-sales service is supported by a team of qualified technicians and a comprehensive stock of spare parts, ensuring reliability and quick assistance whenever needed.

Driven by quality, innovation, and customer satisfaction, Axtra represents the excellence of Italian engineering in the global bottling industry.

Year of establishment:

2006

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2024

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of packing and wrapping machinery

Repair and maintenance of fabricated metal products, machinery and equipment

Installation of industrial machinery and equipment

- Videos

- Catalogue

Automatic monoblock for the distribution and shrinking of PVC capsules, in addition to the labeling of PVC, HDPE and glass containers

An example of an installed line consisting of a monoblock for cleaning, filling and capping and a labeling machine

Automatic machine to check for any impurities inside full capped containers

- Contact Information

- Business Proposals

Company:

AXTRA SRL

Web site:

Address:

VIA I MAGGIO, 46/A

City:

SAN MARTINO DALL'ARGINE (MN)

Zip Code:

46010

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

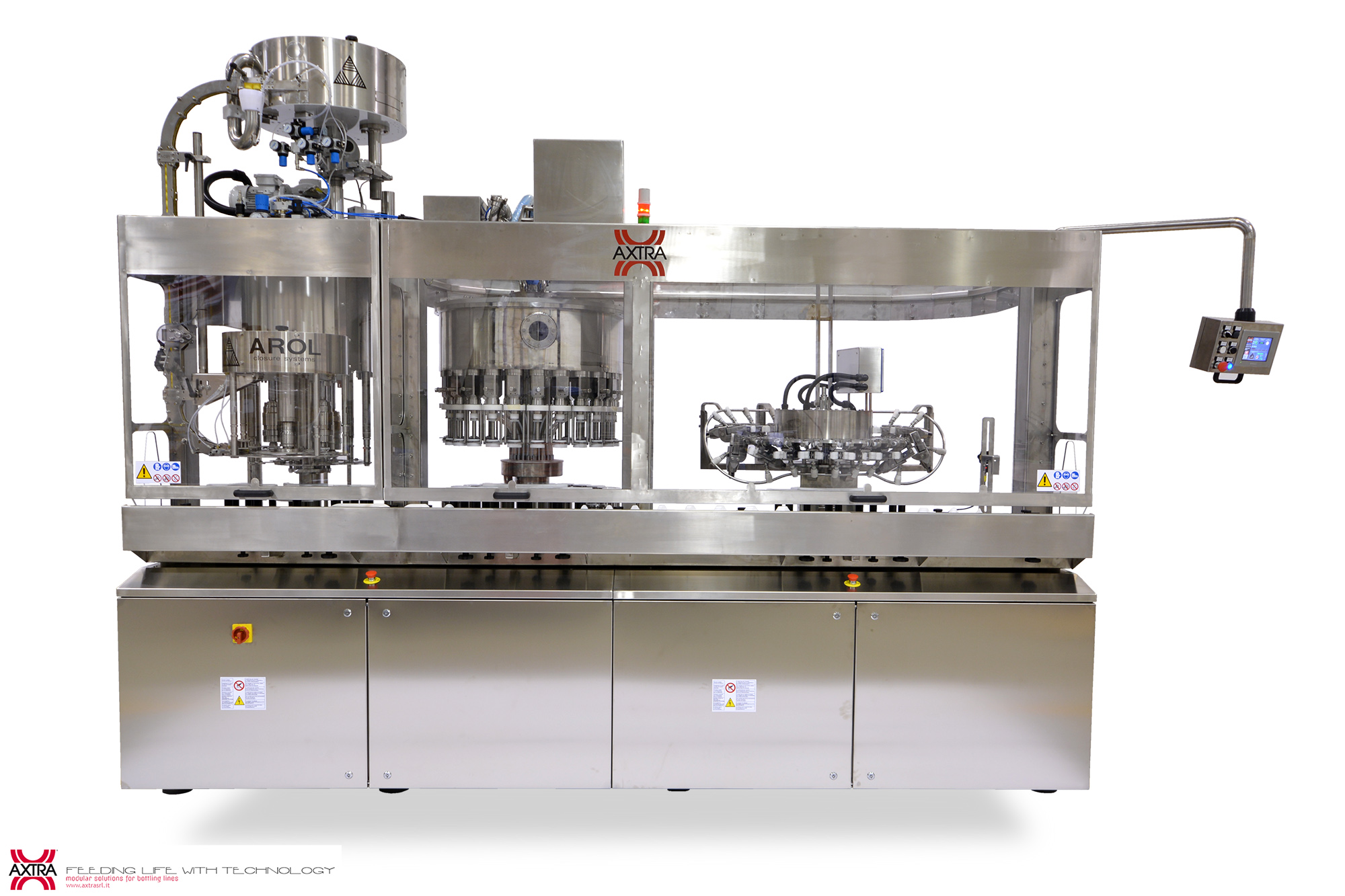

Cleasing, filling and capping monoblock

Monoblock for Cleaning, Filling & Capping

Axtra presents a high-performance rotary monoblock that integrates, in a single footprint, the three essential functions of internal container cleaning, filling and capping — delivering the flexibility of individual machines within one compact structure.

Designed for those who demand seamless production and superior efficiency, this integrated system offers:

Compact footprint & structural integration: By combining multiple processing steps into one chassis, the machine significantly reduces overall dimensions compared to separate units.

Optimised components and streamlined operation: Fewer mechanical interfaces, unified operator management, and simplified handling enable lower maintenance and easier operation over time.

Cost-efficient investment & operation: The consolidated design leads to a lower purchase cost and reduced operational expenses, thanks to fewer materials, reduced footprint and simplified workflows.

Our monoblock is engineered to support a wide variety of container types and closures — from natural corks and synthetic stoppers to aluminium screws, crown caps, plastic pre-threaded caps and T-caps — all managed within a single unified machine.

Axtra’s in-house technical office carefully analyses each customer’s production requirements, then configures the system to meet specific output, format changeover and product characteristics. The result is a turnkey solution that integrates seamlessly into existing lines or becomes the backbone of new installations.

We offer full support from design to installation: we handle machine assembly, operator training and after-sales service through qualified technicians and a dedicated spare-parts inventory. This ensures that your investment keeps delivering performance consistently, with minimal downtime and maximum reliability.

By choosing Axtra’s monoblock solution, you align with the very best of Italian engineering — blending innovation, precision and manufacturing excellence for the global bottling industry.

MINILINE: Compact Italian Technology for Bottling Efficiency

MINILINE is Axtra’s linear bottling monoblock designed for productions ranging from 100 to 1,800 bottles per hour.

This modular solution embodies the essence of Italian engineering — combining functionality, flexibility, and space-saving design.

Thanks to its compact structure, MINILINE integrates all the essential functions of a complete bottling and packaging line within a reduced footprint. Cleaning, filling, capping, and labelling operations are harmoniously coordinated to deliver continuous, reliable performance even in limited production spaces.

Its modular configuration allows each system to be customized according to the customer’s specific needs, making it ideal for small and medium producers who require professional performance and high-quality results.

Developed and manufactured entirely in Italy, MINILINE represents Axtra’s commitment to innovation, efficiency, and durability — offering a turnkey solution that guarantees ease of use, quick installation, and low maintenance.

Whether used as a stand-alone system or integrated into an existing production line, MINILINE delivers all the advantages of advanced bottling technology in a compact, cost-effective format — a true expression of “Made in Italy” excellence for the global beverage industry.

Axtra Monoblock: Tailored Italian Technology for Complete Packaging Solutions

Axtra’s packaging monoblock combines, within a single compact structure, the key functions of container cleaning and external drying, capsulation, and labelling.

This integrated model retains the full performance of individual machines while offering all the advantages of reduced dimensions, simplified handling, and optimized operation.

Designed according to the highest standards of Italian engineering, this monoblock represents an example configuration — a demonstration of Axtra’s capability to integrate multiple packaging functions in one efficient system.

Each monoblock can be fully customized based on the customer’s production needs, including only the required packaging functions. Whether your process involves cleaning and labelling, capsulation only, or a complete end-of-line solution, Axtra designs the ideal layout to fit your space, product type, and output capacity.

The benefits of this modular approach include:

Compact footprint – multiple operations integrated in one chassis to save space.

Streamlined workflow – single operator interface and unified control system.

Operational efficiency – lower maintenance, faster setup, and reduced costs.

Custom flexibility – every machine tailored to specific production requirements.

Axtra’s monoblocks can be integrated into existing lines or supplied as standalone units, providing seamless compatibility with different production environments. From design and assembly to installation, operator training, and after-sales support, Axtra guarantees reliability, precision, and lasting performance.

Combining technological innovation, craftsmanship, and flexibility, Axtra delivers bottling and packaging solutions that embody the excellence of Italian manufacturing — customized systems built to enhance productivity and elevate quality across global markets.