- About us

- Company details

Ital Tools offers a full range of high quality precision tooling for various and different industrial applications in the field of woodworking, chipboard, mdf, plastic and aluminium alloys. This includes diamond router bits for CNC machines (PPD03), hard metal end mills (FEW05), solid carbide drill bits with teflon coating (PHM19), tungsten carbide tipped saw blades for panel saws (LCU13), holders for CNC machines (MAN02) and collets (PNZ05)

Year of establishment:

2008

Number of employees:

UP TO 2 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2018

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of interchangeable tools

Wholesale of telephone and communication equipment

- Videos

- Catalogue

Entrance of the cut in material

No documents uploaded

- Contact Information

- Business Proposals

Company:

ITAL TRADE SRL

Web site:

Address:

VIA DON MINZONI 123

City:

CERTALDO (FI)

Zip Code:

50052

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Carbide circular saw blade to cut bilaminated panels LCU11

Performances of LCU11 carbide saw blades: Up to 25 sharpenings to extend the product life-time thanks to tip thickness 30% greater than standard tips. Improved precision: the blades are manufactured with centesimal tolerances due to the use of diamond grinding wheels with ultra fine grain. Vibration and noise reduction: Body slots laser together with thermoplastic polyurethane filling considerably reduces vibrations and minimize noise. Increased blade life up to 70% compared to traditional tools: anticorrosive coating of 6 microns protects the tool for its entire cutting life and leads to reduce friction, resin build-up and improves chip ejection.

High-speed solid carbide spiral cutters Z3+3 - ULTRALONG coating

Application: panel sizing and cutting of chipboards, MDF, OSB, plastics and laminate. Machines: CNC Routers Features: - High-tenacity solid carbide micrograin; - Feed rate 20 m/min ** by particular geometry of cutting teeth Z=3+3; - Excellent finish on the upper and lower side of panel; - Longer life up to 150% more compared to the traditional tools thanks to the special coating ULTRALONG. ** Providing that panel is well fixed on the machine.

Light alloy jointing cutter with exchangeable diamond knives for edgebanders FFD18

Suitable for milling units for very quiet jointing of solid wood and wood-based panels with and without coating, focusing particularly on the reduction of unbalance and noise. Axial angle 35°, upon request angle 45° or 54,9°.The code for spare knife order is FFD18.COL

Carbide cutter for machines SCM Olimpic K230, K360, K560

Carbide cutter for SCM machines code 07L0247781A, 07L0247780H, 07L0216873H, 07L0216872F

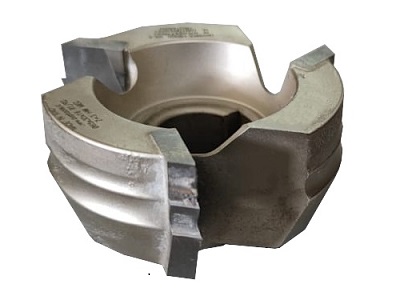

Planing cutterheads with Centrolock system

Finishing cutterheads Centrolock with HS self positioning knives.

The Centrolock system allows to change knives quickly and precisely thanks to the self-locking system. HSS high-speed steel knives are suitable for soft woods and are also available as spare parts.