- About us

- Company details

FRATELLI PEZZA was founded in 1970 as a manufacturer of mechanical and industrial systems in general, and then subsequently dedicated itself to the sector of machinery for glass processing. The company is particularly at the forefront in the construction of glass sandblasting and marking systems, thanks to the technical skillfulness of the founder Alessandro Pezza, who was the first to design and launch a fully automatic sandblaster on the world market.

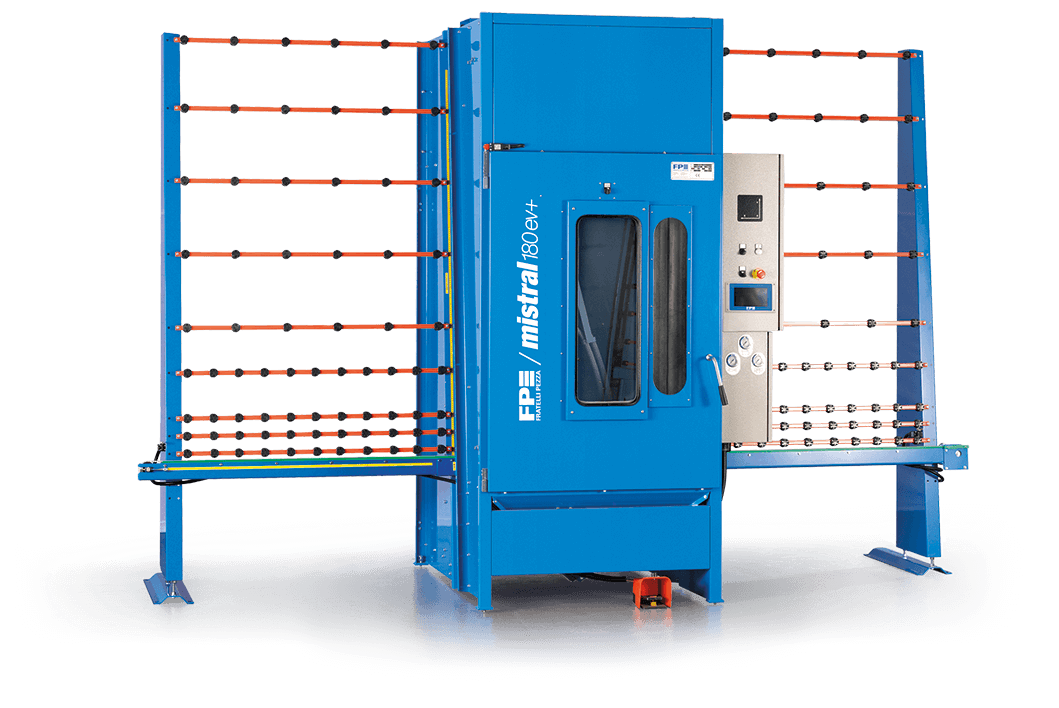

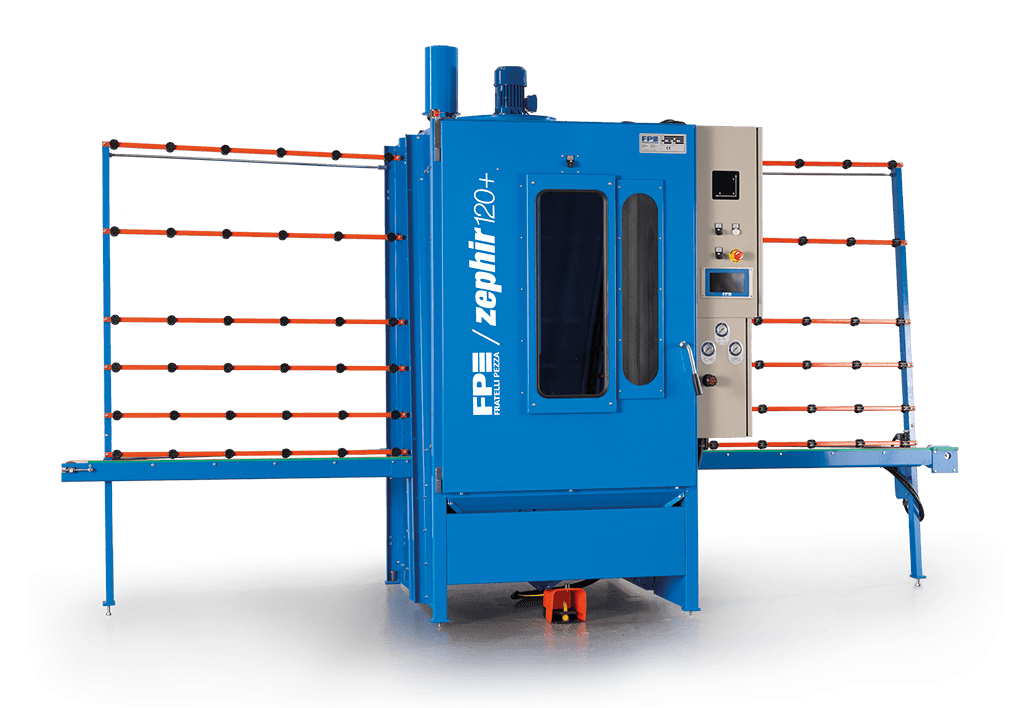

Fratelli Pezza produces a wide range of machines that meets any need in the field of sandblasting and marking of flat glass. From small portable sandblasting machines and marking equipments to the most complex automatic sandblasting systems such as the MISTRAL EV+ series, which represents the top of the range of its production and allows the creation of shaded and multiple-zone sandblasting, passing through the ZEPHIR+ series, an automatic cabin with basic functions that represent an exceptional compromise between quality and price. The GHIBLI series manual cabin complete the range of sandblasting systems. In addition to the portable glass marking device MARKER T, Fratelli Pezza has EASYMARKER line in its catalogue, automatic devices that allow the glazier to create marks and logos ensuring excellent productivity and extreme engraving precision.

Year of establishment:

2008

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2024

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of other machine tools

- Videos

- Catalogue

Sandblasting machines for flat glass

Glass marking is often a mandatory requirement but it is also a great opportunity to your company.

MIX30PRO, Protective and anti-fingerprint coating for sandblasted glass

- Contact Information

- Business Proposals

Company:

FRATELLI PEZZA S.R.L.

Web site:

Address:

VIA ING. V. BALDUZZI 29

City:

CLUSONE (BG)

Zip Code:

24023

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

MISTRAL EV+ SERIES, automatic glass blasting cabin

The MISTRAL EV+ series represents the top of Fratelli Pezza’s product range and it is available in 3 version: 120, 180 and 260. It’s a solid and compact equipment very easily usable by every operator, which provides high productivity despite the very low electrical and compressed-air consumption. The MISTRAL EV+ offers several working options, included the shading and the zonal blasting. It’s possible to operate in automatic or manual mode and the maximum working height can be doubled being the cabin open topped. The machine is equipped with a high-efficiency filtration system with automatic separation of the waste dust from the abrasive material, which is therefore recovered and recycled. Thanks to special airtight rubber shelters placed on the side openings of the cabin, the dust is not allowed to flow out in the surrounding environment. All models are equipped with MirrorProtection, a revolutionary system that limits the accumulation of electrostatic charge inside the cabin which eliminates sparks while blasting mirrors. All components and parts subject to wear are made of highly abrasion-resistant materials, to ensure optimal performance and long life. All models comply with Industry 4.0 requirements.

MARKER T-LINE, portable glass marking equipment

The sand-jet marking machines allow to carry out a permanent mark on the glass in a very cost-effective way and that’s why such technique is best performing and definitely preferable to laser and ink printing. The Marker 101T & 301T are portable units and enable to carry out the marking operation on already installed glass panels. The units are equipped with a built-in dust filter and an abrasive material container and the stencil with the logo, made of highly abrasion-resistant stainless steel, can be rotated so that the logo can be carried out in any position. The MARKER 101T & 301T are also equipped with a timer in order to optimize the production time and preserve the steel mask from premature wear, and enable to imprint logos up to 30 mm diameter.

ZEPHIR+ SERIES, automatic glass blasting cabin

The automatic series ZEPHIR+ represents an excellent compromise between quality and price. It’s a solid and compact equipment very easily usable by every operator, which provides high productivity despite the very low electrical and compressed-air consumption. The Zephir+ offers several working options, it’s possible to operate in automatic or manual mode and the maximum working height can be doubled being the cabin open topped. The machine is equipped with a high-efficiency filtration system with automatic separation of the waste dust from the abrasive material, which is therefore recovered and recycled. Thanks to special airtight rubber shelters placed on the side openings of the cabin, the dust is not allowed to flow out in the surrounding environment. All models are equipped with MirrorProtection, a revolutionary system that limits the accumulation of electrostatic charge inside the cabin. All components and parts subject to wear are made of highly abrasion-resistant materials, to ensure optimal performance and long life.

MIX30PRO, Protective and anti-fingerprint coating for sandblasted glass

Sandblasting is one of the most used techniques for glass decoration as well as to ensure privacy in public and private environments. The sandblasted surface, becoming porous, tends to capture fingerprints and impurities, with unsightly results. For this reason, Fratelli Pezza, leader in the production of sandblasting machines for flat glass, has been offering quality products for the care and protection of sandblasted surfaces for more than 20 years, so that its customers can create design solutions suitable for any environment. MIX 30 PRO is the enhanced version of the protective coating for sandblasted glass Fratelli Pezza has been selling for many years. The new formula is the result of an innovative technology which creates a filler that prevents the adhesion of dirt, limescale, fingerprints and impurities that tend to deposit into the micropores created by the sandblasting process. The treated surface can be immediately handled, packaged or laid on site.

The product can be applied on entirely, partially, lightly decorated sandblasted glass or frosted glass. It is ideal for partition walls, shower boxes, doors, parapets, stairs, windows, tables, furnishing elements, kitchen tops and splash guards, bathroom furniture, floor tiles and many other items.

For a proper application it is necessary to clean the surface to be treated and wait until the surface has completely dried before applying the product. After that, the operator has to spray a small amount of product onto the surface and spread it with a clean microfiber cloth until it dries evenly over the surface. The coverage is about 100 m2 / liter with a single pass even on etched or very porous sandblasted surfaces. With proper maintenance, the treatment lasts for more than 6500 washes.

The coating does not yellow, resist to UV rays and it is compatible with many materials: aluminum, steel, gaskets, ceramic, marble, wood, corian, etc. The treated surface can be installed with the use of neutral silicone, acetic or MS polymer.