- About us

- Company details

MASTER TECHNOLOGIES core business is design and construction of technologically advanced and high performing packaging systems, for the bakery and chocolate industries, including automatic handling, and flow-pack wrapping of the products, starting from the oven or cooling tunnel exits.

We like to consider ourselves as solution providers rather than industrial equipment manufacturers, nevertheless open minded approach as well as a deep understanding of bulk production issues allowed us to develop, over the years, a wide range of machines suitable to meet almost any requirement.

Year of establishment:

2010

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2019

Activities:

Manufacture of packing and wrapping machinery

Manufacture of machinery for food, beverage and tobacco processing

Manufacture of all other various special-purpose machinery nec

Wholesale of other various machinery and equipment nec

Project management activities related to integrated engineering

- Videos

- Catalogue

The easy opening applicator by Master Technologies is an impressive device capable of adding value to the flow-pack packages. It finds its ideal application in all types of packaging containing multiple products. The easy and controlled opening allows most of the package to remain intact, enabling the user to consume only part of the contents while keeping the remaining products safely inside the pack.

The UBC U-Shape Buffering System by Master Technologies is an advanced buffering solution designed to balance production flow between incoming products and the packaging area. The system consists of an infeed conveyor and an outfeed conveyor connected by a sliding 180° curved belt, ensuring smooth and continuous product handling. Operating on a First-In, First-Out (FIFO) principle, the UBC system allows products to be accumulated and released according to the real-time availability of the packaging line, guaranteeing an efficient and reliable flow. The unit can handle products arriving in perfect rows, organized lines, or completely random patterns, while delivering them at the outlet in the exact same configuration in which they entered the buffer.

No documents uploaded

- Contact Information

- Business Proposals

Company:

MASTER TECHNOLOGIES S.R.L.

Web site:

Address:

VIA VITTIME DELLE FOIBE 4

City:

CIRIE' (TO)

Zip Code:

10073

E-commerce:

Tag:

No business proposals uploaded

- Map

HIGH SPEED TRANSVERSAL EASY OPENING APPLICATOR

A strip, 4 mm wide, is cut from a reel of material in continuous motion and sealed transversaly onto the inner face of the packaging material.

Independent brush-less servomotor of the crimper head is synchronized with the wrapping machine and with the speed of the wrapping material.

The Easy Opening Applicator includes two temperature controls for the heating of the crimper and the counter roller for the sealing.

Intuitive touch screen panel allows easy set and memorize various parameters for different products and shows any alarm messages present in the machine.

The Easy Opening Applicator is produces in two different sizes. The TTH-250 for packaging material up to 230mm wide and the TTH-320 with packaging material up to 300mm wide

Masterwrap MW22.0.BS400

The Masterwrap MW.22.BS400 is the most versatile horizontal flow wrapping machine of Master Technologies offering different sealing technologies and a wide variety of automated applications.

The fully Servo Driven Wrapper has been optimized with regard to safe operation, easy cleaning, simplified maintenance and steady product changeover. Altogether helping food manufacturer to significantly increase their packaging production.

The Masterwrap MW22.0.BS400 can be supplied in several versions, for Single Pack, for Multipack, for Length Slug and for Cross Slug.

Different kind of automatic feeders are offered with the wrapper.

The speed is up to 600 packages per minute.

VSL Volumetric Loader for Biscuits and Crackers

Master Technologies sets a new standard to biscuit packaging with its new fully automated packaging line.

Proven servo technology cares for reliable and soft slug portioning and gentlest transfer into the rod chain. Thus leading to an exceptional packaging performance up to 360 slugs per minute at an uncompromised compact footprint and with only 10 degree feeding decline.

The VLS Volumetric Loader can be assembled up to 12 channels and in the special version, can be manufactured with 16 channels.

The base VLS has 3 servomotors for the portioning, loading and stopping the products.

Each individual channels can be stopped automatically incase of missing products and restart, as well automatically, when products are available.

Intuitive touchscreen operation allows easy to set and memorize various slug format recipes.

The modern construction allows easy cleaning together with excellent accessibility all over the system. Working conditions can be visually inspected at any time. Altogether significantly reducing maintenance efforts.

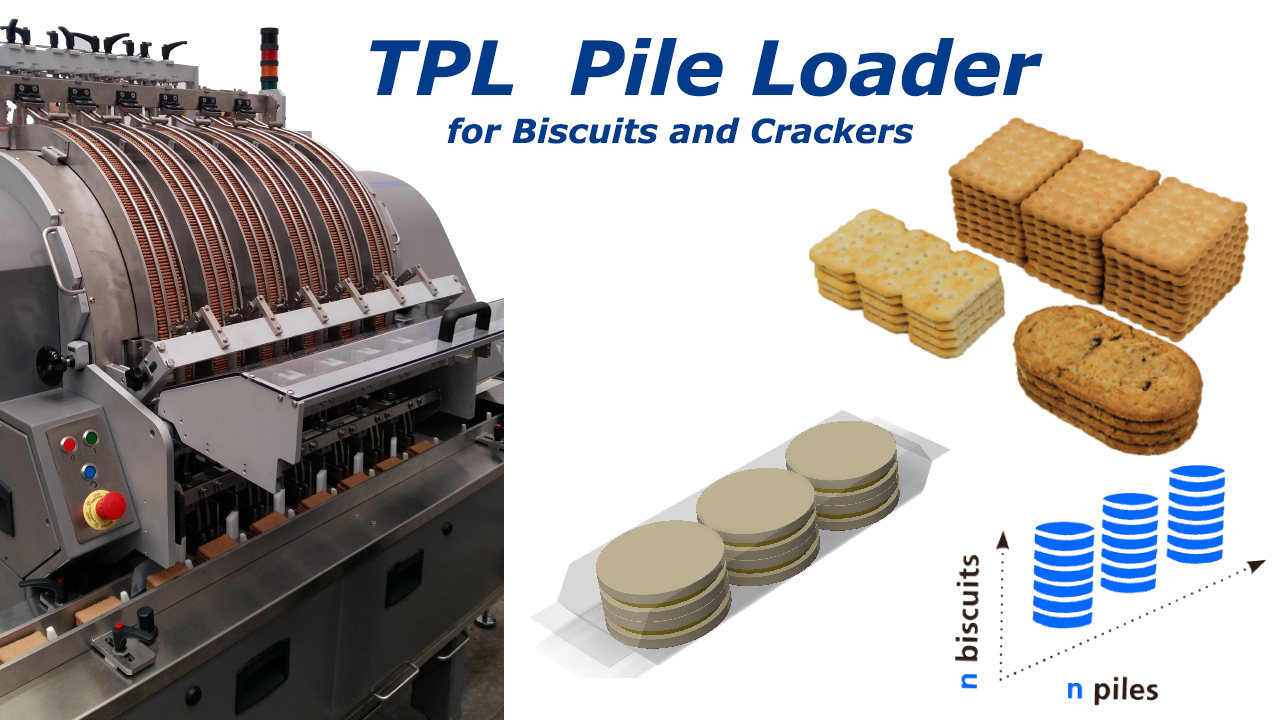

TPL Pile Loader for Biscuits and Crackers

Master Technologies fully Servo Driven TPL Pile Loader is a reliable and soft pile counting-portioning and gentlest transfer into the wrapping machine’s chain.

Leading to an exceptional packaging performance up to 500 piles per minute with 50 loading cycles.

It can be assembled up to 12 channels and in the special version, can be manufactured with 16 or more channels.

The base TPL has 4 servomotors for the portioning, loading the piles.

As option, thanks to the “Stop & GO” feature, each individual channels can be stopped automatically in case of missing products and restart, as well automatically, when products are available.

Intuitive touchscreen operation allows easy to set and memorize various piles format count recipes.

The modern construction allows easy cleaning together with excellent accessibility all over the system.

Working conditions can be visually inspected at any time. Altogether significantly reducing maintenance efforts

MGL Grouping and Labeling System (Multipack)

Master Technologies MGL Multipack Grouping and Labeling System is a new middle range speed equipment for grouping primary flow-pack packages and present them as multipack, held together by a label.

With the input up to 400 packages per minutes the MGL model can be applied to several existing flow-pack lines present on the market. The output can reach 80 multipack groups per minute.

Higher speed version of multipack labeling system is available for speed up to 600 packages per minutes at the entrance and 200 multipack groups per minutes at the exit.

The machine applies labels on the bottom and on the top of the group of packages that previously was placed on edge thanks to the twisting belts present on the entrance of the machine.

Intuitive touchscreen operation allows easy to set and memorize various groups count recipes.