- About us

- Company details

S.A.V. is a reliable Italian Company, specialized in hot forging of many types of steel (carbon, hardening, tempering, alloy, common, etc. except stainless steel) of weight from 0.5 up to 12 kg, thanks to a large machine park composed of 4 presses (1000 tons, 1200 tons and 1600 tons).

SAV operates like a 360° partner, supplying the finished products to important manufacturers of parts for agricultural machines, earth-moving machines, industrial vehicles, and hydraulics.

Year of establishment:

1963

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2019

Export turnover:

0

Activities:

Forging and shaping metal and powder metallurgy

- Contact Information

- Business Proposals

Company:

S.A.V. S.R.L.

Web site:

Address:

VIA NAZIONALE 1/A

City:

CAINO (BS)

Zip Code:

25070

E-commerce:

Tag:

No business proposals uploaded

- Map

Tie Rods

S.A.V. has two rolling mills that make us highly specialized in the production of tie rods, forks, pivots, levers, crankshaft, and transmission heads. These products are used in many sectors, mainly for agricultural tractors, industrial vehicles, and hydraulics.

Web site

https://www.savsrl.com/en/

Pump bodies

S.A.V. manufactures several components of the hydraulics sector. Apart from the pump bodies of the picture, there are many cylinder end plugs, or ball joint ends for hydraulic cylinders.

Web site

https://www.savsrl.com/en/

Flanges

S.A.V. can easily manufacture several kinds of flanges, from gears to rings. The ones in the picture are components of industrial vehicles, but there are many others used in other sectors.

Web site

https://www.savsrl.com/en/

Support levers for lift systems

S.A.V. manufactures several support levers for lift systems, especially for the agricultural sector. Similarly, it produces many kinds of flanges and hitches and tests them with some safety controls.

Web site

https://www.savsrl.com/en/

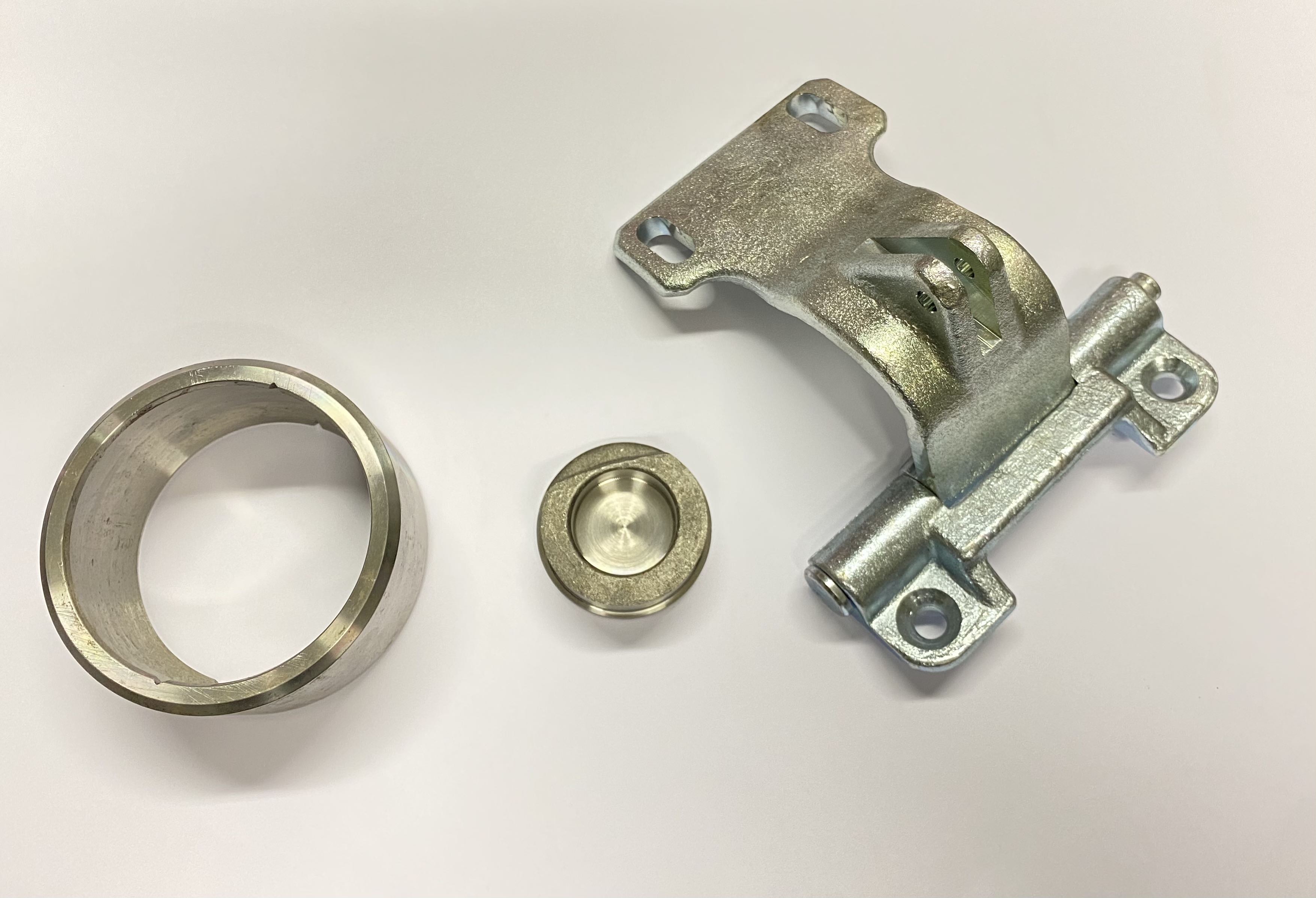

Assemblies of hinges and additional services

Apart from the hot forging process, S.A.V. offers many additional services to meet the clients' needs. Over the years, we have strengthened solid partnerships with subcontractors in order to offer finished products according to the clients' specifications.

Some of the phases that we usually manage are heat treatments, precision machining, assembling, and surface finishing (such as galvanizing, electrocoating, phosphating, induction hardening, and many more)

Web site

https://www.savsrl.com/en/