- About us

- Company details

AURIL&GOND is a company that operate in the steel industry and aims on the national and international market as a supplier of electromagnetic stirring systems.

The experience gained over the years has allowed the company to become a consolidated benchmark in the design and production of electromagnetic stirrers.

AURIL&GOND differs for a total control and internal management of every production stage from design to manufacture and final tests.

There is a continuous exchange of information between departments in order to maintain high standards and constantly increase its know-how.

The research and development also contributes to steadily increase the reliability of our products as well as give new solutions to the customers.

FASTER. BETTER. COMPETITIVE.

Year of establishment:

2008

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2023

Activities:

Manufacture of non-domestic air conditioning equipment

Manufacture of machinery for metallurgy

Manufacture of machinery for mining, quarrying and construction

Repair and maintenance of other special-purpose machinery nec

Electrical, plumbing and other construction installation activities

- Contact Information

- Business Proposals

Company:

Auril & Gond srl

Web site:

Address:

VIA JACOPO LINUSSIO 27

City:

RIVIGNANO TEOR (UD)

Zip Code:

33061

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

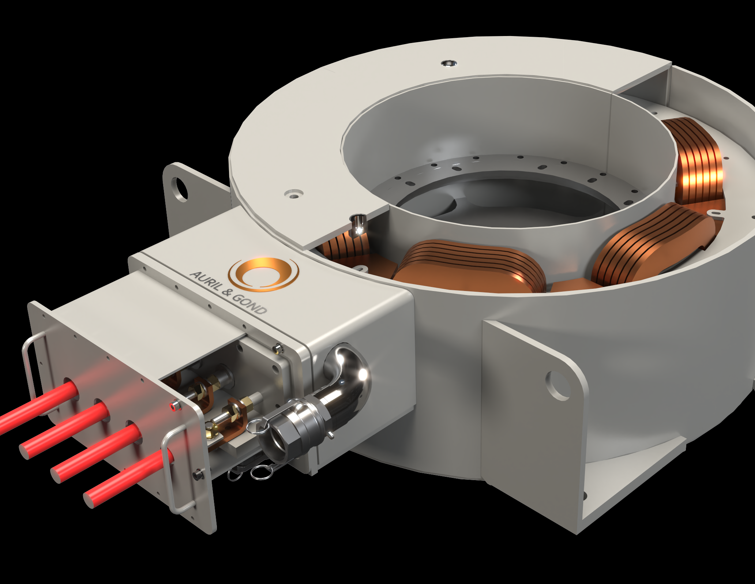

ELECTROMAGNETIC STIRRING SYSTEMS

The electromagnetic stirrer (EMS) are widely used in the iron and steel industry both in the continuous casting phases and in the steel refining process in the ladle.

The use of the stirrers allows to increase the quality and the production of steel and, due to the high metallurgical flexibility they will fit perfectly to the production of steels with different carbon content.

The quality of the surface layer and the internal crystalline structure of the steel depend on the chemical composition, the sildification process and the flow of the liquid steel inside the casting line. In the presence of a variable magnetic field inside the liquid steel, volume forces are induced which impress a main rotation motion and secondary motions along the casting line. The mixing induced with the electromagnetic stirrers makes the heat exchange along the casting line more effective, consequently the solidification process is more homogeneous and promotes the formation of equiaxed zones.

Electromagnetic stirrer are user in continuous casting processes, mainly to increase the quality and the production of steel.

Web site

https://www.ems-ag.com/en

Water cooling System

The cooling system with demineralized water it is used to remove the heat produced in the coils for Joule effect and to maintain the winding temperature below the limit value related to the thermal insulation class.

The water system ensures a longer life of the electric insulation of the stirrer and, due to the high efficiency, is able to reduce energy consumption.

Web site

https://www.ems-ag.com/en

Inverter Switchboards

Our inverter switchboards are equipped with a sliding system that allows easy installation / maintenance of the main IGBT module. They are composed of static converters at impressed voltage with IGBT modules, digital regulation with vector control, capacitor bank, microprocessor control unit and auxiliary circuits (power supplies and transducers). The inverter is specifically designed for critical applications and is designed with the latest and proven technologies, in a modular design for easy installation and maintenance. All Power components are sized to ensure operation of the converter even in the most severe service and load conditions. The power components (diodes and IGBTs) are cooled by forced ventilation. The static converter is available in different sizes up to a maximum power of 4 MW in the case of 8 modules in parallel.

Web site

https://www.ems-ag.com/en

LINEAR EMS For EAF, LF and TUNDISH

PRODUCTIVITY INCREASE AND COST REDUCTION

The life of the furnace is increased. It is not necessary to use burners at high temperatures for long periods and tap to tap time is reduced, guaranteeing greater heat exchange and higher productivity.

REDUCTION OF CONSUMPTION

The AURIL&GOND stirrer reduces gas consumption by about 15% thanks to mixing with consequent homogenization of the temperature.

TEMPERATURE AND CHEMICAL HOMOGENIZATION OF THE ALLOYS

With the use of the electromagnetic stirrer we have a drastic reduction of the temperature difference between the upper and lower part of the molten bath which stands at less than 5°C a few minutes after switching on the stirrer. This difference without the use of the stirrer is normally between 50 and 80°C. This therefore also guarantees an increase in the speed of dissolution of the alloys in terms of time.

SLAG FORMATION REDUCTION UP TO 25%

The mixing effect produced by the AURIL&GOND stirrer allows lower temperature gradient in the liquid bath with a consequent lowering of the surface temperature. Using the stirrer makes less necessary argon gas mixing, as a result, slag formation is substantially reduced.

Web site

https://www.ems-ag.com/en