- About us

- Company details

LaserPin specializes in providing equipment for the perforation of materials films on moving lines of productions. Strengthened by the experience gained and established over time, we develop machinery, units and tools designed to meet the specific, customised needs of our customers by recommending and designing the appropriate technology. The strength of our company is the ability to manufacture equipment for all kinds of perforation of different types of materials on a moving web. We have a long-standing experience in the global market and we provide our customers worldwide with high quality, state-of-the-art solutions.

Perforating, punching, cutting, embossing, laser units and relative spare parts.

The company was also within the first ones to quickly and efficiently adapt part of the production to manufacturing hygienic and surgical face masks, alongside Italian Government and relative institutions.

LaserPin has in fact supplied firstly some of the majors companies in the wholesale retails chain in Italy, then the professional and private sector as well.

Year of establishment:

2013

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

Not available

Reference year of turnover:

2022

Export turnover:

0

Activities:

Manufacture of other technical and industrial textiles

Manufacture of plastics and rubber machinery

Manufacture of medical and dental instruments and appliances

Repair, maintenance and installation of machinery and equipment

Repair and maintenance of machinery

Repair and maintenance of other special-purpose machinery

Installation of other industrial machinery and equipment

- Contact Information

- Business Proposals

Company:

LASERPIN S.R.L.

Web site:

Address:

VIA CARLO GIUSEPPE MERLO 1

City:

MILANO (MI)

Zip Code:

20122

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Easy change 60 perforating unit

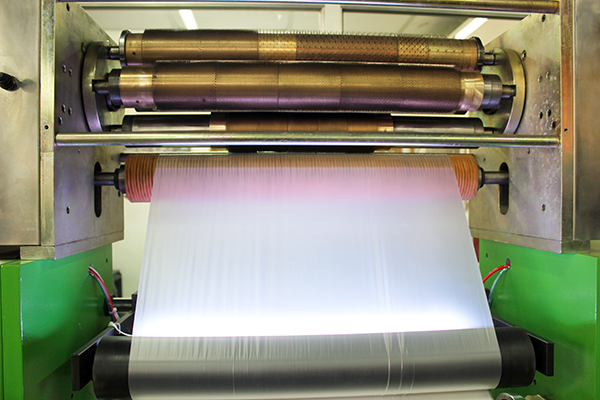

Example of cold micro perforation unit with its own structure and rewinder.

It is ideal for customers who regularly need different kinds of perforations on one line. It has up to four perforation rollers integrated in the unit, allowing a fast and easy change of a roller to adapt to different perforation requirements. The big plus of this feature is that there is no need to stop the production while changing the roller. The perforation rollers are changed by a flywheel.

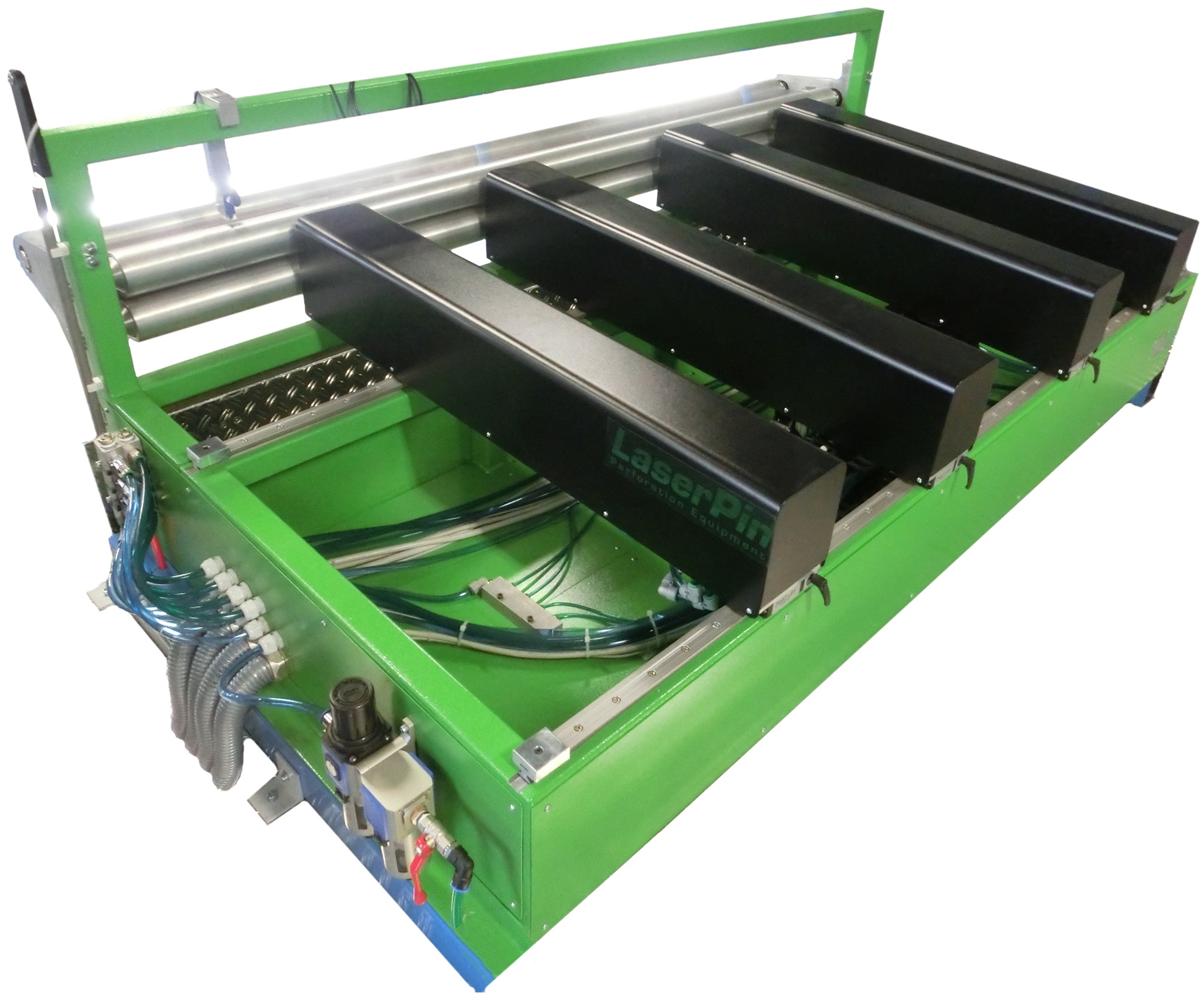

LPA &LPA2

Example of macro perforation unit. This particular model is based on company entry level "LP". The LPA operates with multiple punching tools. The number of punching tools required depends on customers needs. The big plus of this model is its openable bridges giving easy access to the punching tools to move, change or do maintenance on them.

HLP - Agrigultural equipment

The HLP a macro perforating unit able to make holes on a moving web up to a maximum thickness of 800 microns. It makes round holes of big sizes, mostly on plastic films. The great advantage of the HLP is the great adaptability to agricultural needs. One example is the common mulch films.

LR4 - Laser unit

The LR4 is a machine equipped with a CO2 Laser, which emits a beam of light at a pre-set infrared wavelength. An optic system concentrates the beam on a small surface of the material. The heat generated by the laser sublimates the material, thus creating desired holes. The diameter of the holes is regulated by an innovative 4.0 software that sets the strength of the beam on the material, which runs at a constant speed. The laser unit is thus able to perforate materials with different strengths and thicknesses. It also works on materials made of different layers. The control system is supported by an encoder and a trigger system. This means the software can vary the size of the holes and the distance between them, thus adapting to different materials and requirements.

FFP2 NR sanitary face masks

The company was within the first ones to quickly and efficiently adapt part of the production to manufacturing hygienic and surgical face masks, alongside Italian Government and relative institutions.

We have in fact supplied firstly some of the majors companies in the wholesale retails chain in Italy, then the professional and private sector as well.

Chirurgical MASK-LASE 1 and sanitary face masks FFP2.

Following European and international laws®ulations, obtaining both a European and an International certificate, HALAL.

LaserPin masks are 100% Made in Italy, using a concept of comfort plus an innovative and ergonomic shape. Soft, high-quality materials.

Those have been company trade mark, extremely well received to our customers.