- About us

- Company details

Our Company has been operating in the field of automation and packaging for more than thirty years, with a production site in Turin, Italy. We produce packaging machines starting from basic models, such as our Miniflow 400, up to fully automated solutions for high-speed lines.

In order to keep the two productions separate, as they are intended for a different audience, our group is divided into DM PACKAGING (which produces standard machines for small and medium-sized enterprises) and HBTS (high-speed lines, all customized, intended for large industry. )

We have a research and development office and an internal design office, so we can offer any type of solution truly tailored to the customer's needs in a short time. We can provide packaging for food and confectionery, but also for medical devices, beauty products, etc.

Besides this, two years ago we designed and built a machine for the production of FFP2 / FFP3 masks. Given the experience gained in the field of packaging, we have designed the Line so that it can be interfaced with one of our flow packs, in order to allow the user to individually package the product, in line, thus avoiding any manipulation for a product safer and healthier.

All our machineries are fully Made in Italy, from design to construction, they’re completely electronic with PLC and touch screen for the management of the work cycle and they can be equipped with remote assistance with modem: in this way we can guarantee an extremely quick service, in case of need.

Year of establishment:

2013

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2021

Export turnover:

From 750.000 to 2.5 million Euro

Activities:

Manufacture of machinery and equipment nec

Manufacture of general-purpose machinery

Manufacture of packing and wrapping machinery

- Contact Information

- Business Proposals

Company:

DM PACKAGING GROUP S.R.L.

Web site:

Address:

VIA SALERNO 31

City:

TORINO (TO)

Zip Code:

10152

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Miniflow Mickey Edition

The new version of the Miniflow400 is the result of a combination of technology and innovation, a compact machine with a unique design.

Robust and cantilevered structure, it can be equipped with many accessories such as the flat system on water-cooled hot wheels, No Product/No Bag, No Gap/No Seal and many others.

User friendly intuitive menus HMI as well as reduced change over time, easy to perform interface tasks with any equipment up stream, solid construction and uncompromising quality of components and materials makes of any DM wrapper a valuable OEE asset

Web site

https://www.dmpackagingroup.com/

Victoria 600

Sturdy machine with cantilever construction design ideal for packaging bulky products such as baked goods or multipacks.

Designed for easy access to machine parts, thanks to the exclusive EasyClean it guarantees maximum ease of cleaning and incredible simplicity in maintenance operations.

Examples are the product sliding surfaces that can be opened and inspected without the aid of keys, the 90-degree folding outlet belt for access to the heating elements of the sealing bar, the crumb collection drawers under the supply counter. Other technological pluses such as the belt with central guide guarantee to limit the extra maintenance of the machine. Available with reel 600 or 700.

Options on demand: double reel holder + splicer, extra feeding belt, full personalizations

Web site

https://www.dmpackagingroup.com/

BIM VFFS

A vertical machine specially conceived to work 24/7, up to 100 bpm,

ideal for bulk and free flowing products of all kind, suitable for a variety of different films of all thickness

Web site

https://www.hbts.it/

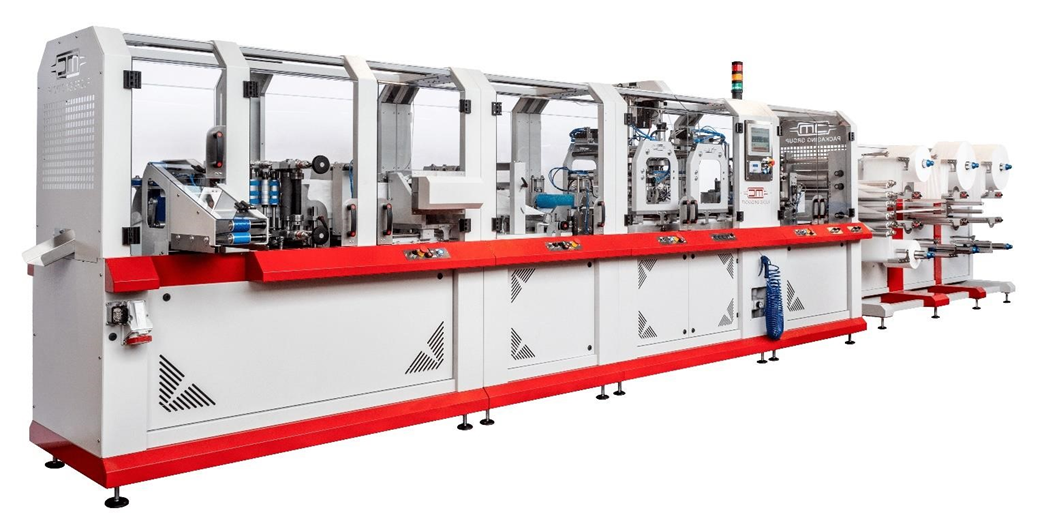

TAURUS 2020

Our Group, very well known in the packaging machine market, two years ago designed and built a machine for the production of FFP2 / FFP3 masks. Given the experience gained in the field of packaging, we have designed the Line so that it can be interfaced with one of our flow packs, in order to allow the user to individually package the product, in line, thus avoiding any manipulation for a product safer and healthier.

The line is fully Made in Italy, from design to construction, it is completely electronic with PLC and touch screen for the management of the work cycle and is equipped with remote assistance with Sevio modem: in this way we can guarantee an extremely quick service.

Web site

https://www.dmpackagingroup.com/