- About us

- Company details

Cimec is an Italian company specialized in the design and construction of bottling lines for water, carbonated drinks, fruit juices, beer, wine and spirits for the food and chemical industry. The brand has been on the market since 1986.

We supply complete lines, exclusively Cimec, from filling to labelling.

Every line we manufacture is the evidence of the passion we put in its construction. We were born as a small artisan company and grew thanks to the dedication and commitment of each member of our team, to become today a solid industrial reality that makes quality and customer support its strengths.

We have an artisan quality with industrial processes and controls: as a craftsman carefully shapes each piece, so we look carefully at every detail, to offer customers our considerable experience. We design and supply customized turnkey solutions for bottling and canning and thanks to a team of experts we help the customer to choose the best solution for his needs.

A constantly supplied warehouse, which guarantees the supply of original spare parts in a short time and a scheduled maintenance service, allow our customers to minimize downtime and to keep the plants always efficient.

Our team of specialized technicians takes care of testing our plants, providing training for line operators, all over the world.

We also offer a personalized technical service by phone, to support the customer at each stage of machine use.

We put passion, quality and dedication to serve all customers in Europe, America, Asia and Oceania.

We are proud to offer our experience and support to the end user and, just like every product we design, every company that chooses us deserves personalized attention.

Year of establishment:

1986

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2021

Export turnover:

From 2.5 to 5 million Euro

Activities:

Manufacture of beverages

Manufacture of machinery for food, beverage and tobacco processing

- Videos

- Catalogue

ISOBARIC FILLING MACHINES FOR WINE

GRAVITY FILLING MACHINE FOR SPIRITS

CAN FILLING LINE FOR BEER

LINEAR ADHESIVE LABELLER FOR CANS

ROTARY LABELLERS FOR BOTTLES AND CANS

No documents uploaded

- Contact Information

- Business Proposals

Company:

CIMEC SRL

Web site:

Address:

Strada Canelli 63/B

City:

Nizza Monferrato TORINO (TO)

Zip Code:

14049

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

ISOBARIC FILLING MACHINES

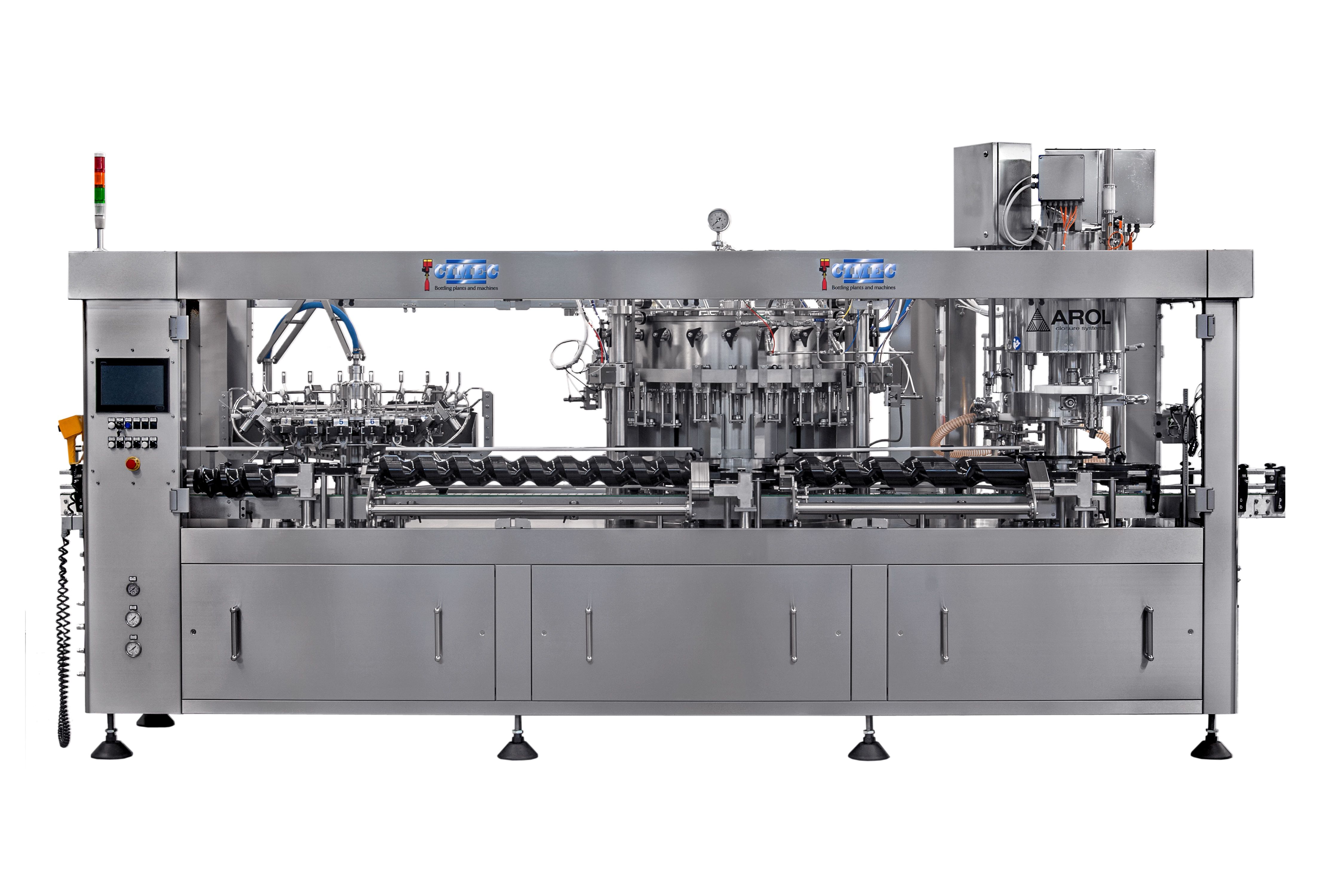

With the range of isobaric fillers, CIMEC boasts consolidate bottling process know-how. The machines are produced using the most advanced technologies, guaranteeing reliability and precision for the user.

Both carbonated and still products can be processed with isobaric fillers with a wide choice of filling valves to be used according to the characteristics of the product to be bottled.

GRAVITY FILLING MACHINES

CIMEC’s gravity, light vacuum and high vacuum fillers are built according to the most advanced technologies, they can fill still products with gravity or light vacuum, having a wide range of available filling valves.

There are many advantages to filling using light vacuum, better priming and absence of dripping. An optional system allows these valves to prevent air from entering the tank preserving the product’s integrity against oxidation and microbiological pollution.

A high vacuum system is applied for very dense products which exploits the difference in pressure between the filler tank and the bottle.

CAN FILLING AND SEAMING MONOBLOCK

BOTTLING IN CAN – a solution that brings together a FILLING TURRET and a SEAMING UNIT in ONE MONOBLOC.

CIMEC, thanks to his over thirty years of knowledge of the bottling process and to satisfy the ever-increasing market demand, has designed a new automatic system for the packaging of canned drinks, using the most advanced technologies, guaranteeing reliability and precision to the user.

Developed mainly in two models, CAN ISO 6/1 S and CAN ISO 12/1 S / S 1, the CIMEC monobloc can meet the needs of breweries as well as producers of soft drinks, still or mineral water, coffee, wine, etc.

The monobloc is composed of a Mechanical Isobaric Filler with I.P.S. filling valves, of a lid feeding group and one or two seamers, depending on the model.

The filler can handle cans of different heights and diameters (STANDARD, SLIM, SLEEK, etc.) and the seamer can close lids of various sizes, depending on the type of can chosen.

Each monoblock is equipped with dummy cans for washing and sanitizing.

LINEAR LABELLERS - self-adhesive or cold glue application

With the linear adhesive labelling machines, CIMEC is able to apply body label, back label, collar and/or state seal.

They can also be equipped with optical centring for label centring and positioning.

Each station can be adjusted horizontally, vertically or diagonally, just like the bottle locking cylinder.

Special devices allow the customer to memorize the position set on each group so as to simplify format change.

The linear adhesive labelling machines are designed for the addition of a cork and relevant end cap distributor, or in the “free-standing” version of the dispenser and end cap.

ROTARY LABELLERS

With the rotary labellers, CIMEC completes its range of labelling machines to cover speeds starting from 2000 b/h. Constant research has allowed us to provide the customer with simple and reliable machines, to guarantee all this.

CIMEC offers systems cam bottle rack handling systems in a grease bath or with electronically controlled movement. It is possible to equip these machines with various optical and mechanical controls in order to detect and orient UV spots, corks with logos or lettering, brands or silk-screen printing on the various containers.