- About us

- Company details

Setecna EPC S.r.l. started its activity in 2002. Over the years Setecna has specialized in the design and production of electronic systems that can manage and control (also remotely) HVAC and DHW production systems. These regulation and remote-control electronic systems can manage both the distribution of the energy in the building (indoor temperature, indoor air quality and humidity management) and the production of the energy in the thermal/cooling power stations (heat pumps and gas boilers management).

We offer products and services for System Integrator, Installers, Maintainers and Heat Pumps and Gas Boilers Producers.

We are able to design and produce customized solutions, combining the skills gained in 20 years of activity:

- Hardware design,

- Software development on Windows, Linux and Web platforms,

- Cloud supervision system development,

- Firmware development on 8-bit (Atmel AVR) and 32-bit (ARM) microcontrollers

- Telecommunications on wired and mobile networks (GPRS, 4G, 5G).

Setecna EPC is a complete company with a technical-know-how acquired in almost 2 decades that allows to follow the customer from the product design to the delivery of the final product, by going through all the intermediate phases (specification definition, engineering, production and hardware testing, firmware development).

The internal production department, optimized for prototypes and small series production, completes the offer towards customers.

Year of establishment:

2019

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2021

Export turnover:

Not available

Activities:

Manufacture of computer, electronic and optical products

Manufacture of other instruments and appliances for measuring and testing nec

Other manufacturing

- Contact Information

- Business Proposals

Company:

SETECNA EPC S.R.L.

Web site:

Address:

VIA ALESSANDRO VOLTA 19/B

City:

DOSSOBUONO VILLAFRANCA DI VERONA (VR)

Zip Code:

37062

Social media:

Tag:

No business proposals uploaded

- Map

DOT is a complete platform, based on an ARM Cortex M4 microprocessor and a 4.3” color TFT display, for the HVAC system control and supervision.

In its most complete version, DOT integrates on board:

- a temperature and humidity sensor;

- an air-quality sensor;

- an analogic / digital input contact;

- an OpenTherm bus for the managements of boilers that support this protocol;

- a Modbus bus for the management of heat pumps for heating and cooling and for the domestic hot water production, for the management of ventilation, integration and/or dehumidification units and energy meters with dedicated firmware;

- a REG bus for the management of the REG System I/O modules (REG-IOA, REG-IOB, REG-IOC, REG-EXP-8), of the temperature/humidity sensors via bus (REG-TH and REG-THL) and air-quality sensors via bus (REG-AQ);

- a Wi-Fi modem for connection to the www.s5a.eu remote system management;

- a mini USB type B 2.0 port to connect via PC.

DOT can be supplied with different hardware configurations and with a completely customizable firmware that allows the total supervision of an HVAC system and its remote management via Web and mobile app.

DOT looks like an elegant display with a 480×272 pixels resolution framed in a rigid white plastic package. This display can be mounted on the wall in a domestic environment in order to be used as a thermostat or in the central heating/cooling station as a control panel.

The end user can interact with DOT via touch on the display or via remote control via Web or mobile app when the Wi-Fi modem on board is connected to Internet. The firmware can be updated via Wi-Fi or via USB using the USB port.

The DOT graphic interface is simple to use: the main functions are shown intuitively for the end user, while the additional configurations are available in advanced menus for the installer and the technical assistance.

Finally, there is the possibility of associating a QR code to each device through which the user can access to the manual or other technical documentation.

Web site

https://www.setecna.it/en/dot-2/

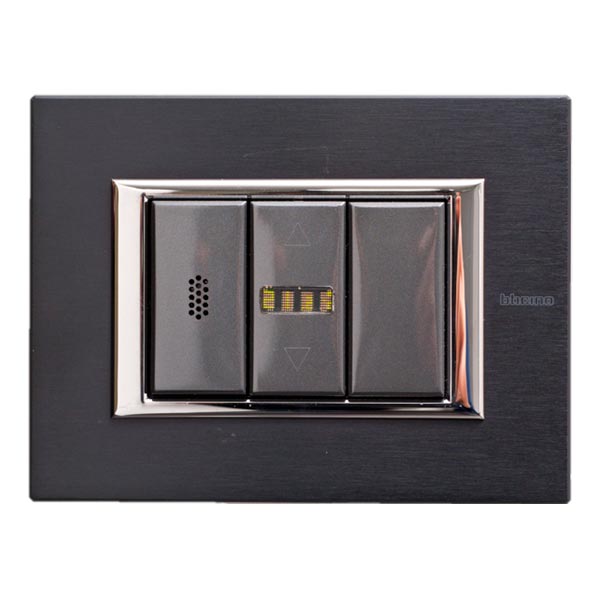

Passive indoor ambient Temperature Probes for coordinated installation with the main flush-mounted civil series

Thanks to the know-how and production processes developed for the REG and Modbus microprocessor sensors, we can realize Passive indoor ambient Temperature Probes for coordinated installation with the main flush-mounted civil series available on the market (BTicino, ABB, Vimar, Gewiss etc.).

It is also possible to order probles with various type thermistors:

- PT 1000

- PT 100

- NTC 10 K beta 3435

- NTC 10 K beta 3980

- NTC 12 K beta 3977

Other types available on request

The probes occupy only one position in the normal flush-mounting boxes 503.

Modbus Flush-mounting microprocessor sensors for ambient temperature and humidity measurement

The Temperature and Humidity Sensors are made directly on the modular components of the main flush-mounted civil series (BTicino, ABB, Gewiss, Vimar, AVE, etc.): they integrate perfectly with any customer aesthetic choice; the high visibility LED display and the touch technology buttons allow to add elegance and functionality to the Sensors.

The sensors are available in 2 versions:

- Ambient Temperature and Humidity Sensor without display

- Ambient Temperature and Humidity Sensor with LED display and Touch Interface

In particular, the versions with LED display and Touch Interface allow to:

- View the ambient temperature and the humidity (% RH)

- View an “Active System” indicator

- View and modify the Room Temperature setpoint

- View and modify the work mode of the room (ON/OFF/AUTO)

The “Active System”, “SetPoint” and “Work Mode” functions can be controlled by the MODBUS Master, which can enable or disable them and set the values.

All sensors are compatible with the Modbus RTU protocol and both versions are available with both 19200 and 9600 baud rate; other configurations can be supplied on request.

Web site

https://www.setecna.it/en/modbus-2/

The REG System is ideal for the radiant systems control and for HVAC systems Management

The REG System main features are:

- Easy to install and configure

- Elegant design components perfectly integrated with the main civil series

Modular and complete functionalities

- Possibility to be integrated with home automation systems and BMS (Konnex, Modbus)

The REG System can manage:

- up to 32 zones;

- up to 8 independent weekly timer

- up to 8 distribution manifolds or 8 direct and/or mix circuits (with mixing valves both with 3-points and 0/10V control);

- both single and twin circulation pumps and their block signal (failover included);

- up to 8 dehumidification, integration and renewal units;

- up to 3 generators via dry contact or 0/10V (Boilers, Heat Pumps, Fireplaces, etc.)

- up to 8 generators via OpenTherm protocol (with specific interface) or Modbus RTU (with specific interface with dedicated firmware) through cascade algorithms;

- Domestic Hot Water production;

- the DHW recirculation pump also through a dedicated clock;

- the solar thermal circuit;

- the dew point control through sensors for cooling radiant system and internal algorithms;

- different generators based on the external temperature, for systems with mixed generators (Heat Pumps and Boilers);

- electrical energy meters;

- a dry contact from the Photovoltaic system;

- up to 8 free analogic probes, 8 free digital inputs and 5 alarm signals (these signals do not affect the regulation, but they are only for control/monitoring).

REG System Main Advantages:

- The Ambient Temperature and Humidity Sensors are perfectly integrated with the most common flush-mounted civil series design (BTicino, Vimar, Gewiss, ABB, …)

- The innovative sensors with LED display combine an elegant design with high functionality for all use conditions.

- Simple and fast installation, easy configuration and commissioning thanks to the built-in display and free configuration software.

- The modular structure via Bus allows to optimize connections, reducing the cables number and installation costs.

- The system is equipped with dozens of presets, suitable for most systems.

An ecosystem of products and services to simplify installation and use:

- can be Remotely managed via PC, Smartphone or Tablet (go to the remote management portal www.s5a.eu).

- the configuration software automatically generates the wiring diagrams to simplify installation operation and reduce errors.

Modbus to OpenTherm Gateway allows a Modbus RTU Master system to manage generators as an OpenTherm Master

The gateways available are with 1 channel or 4 channels.

The gateways provides both in read- and write-mode all the parameters defined by the OpenTherm protocol: it is possible to read the sensors and the errors, to change the set point and the working mode of the generator (heating or DHW production).

Also for the Gateways, by simply modifying the Dip Switch present below the cover, it is possible to set the baud rate (19200 or 9600) and the parity (NONE or EVEN).

Web site

https://www.setecna.it/en/modbus-2/