- About us

- Company details

Bulltec, an Italian manufacturer specialized in innovative machinery for the sort. With over 40 years of experience in the horticultural sector, Bulltec develops tailor-made solutions to meet the specific production needs of small, medium, and large-scale growers. Our systems combine efficiency, precision, and user-friendly technology, ensuring the best results for your production line. Key strengths of our solutions include:

-Electronic sorting by weight, size, and color – with millimeter and gram accuracy

-Industry 4.0 ready systems with advanced data analysis features

-Modular, low-maintenance designs tailored to your crops and volumes

-Versatile lines for products like peppers, onions, zucchini, cucumber, eggplants, potatoes, fennel and more

We design full processing lines — from raw product handling to final packing — to help you optimize quality and productivity.

Year of establishment:

2017

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2022

Export turnover:

Less than 75.000 Euro

Activities:

Manufacture of food products

Processing and preserving of fruit and vegetables

Processing and preserving of potatoes

Other processing and preserving of fruit and vegetables

Manufacture of other general-purpose machinery

- Contact Information

- Business Proposals

Company:

BULLTEC S.R.L.

Web site:

Address:

M5UXCR1

City:

cesena (FC)

Zip Code:

47521

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

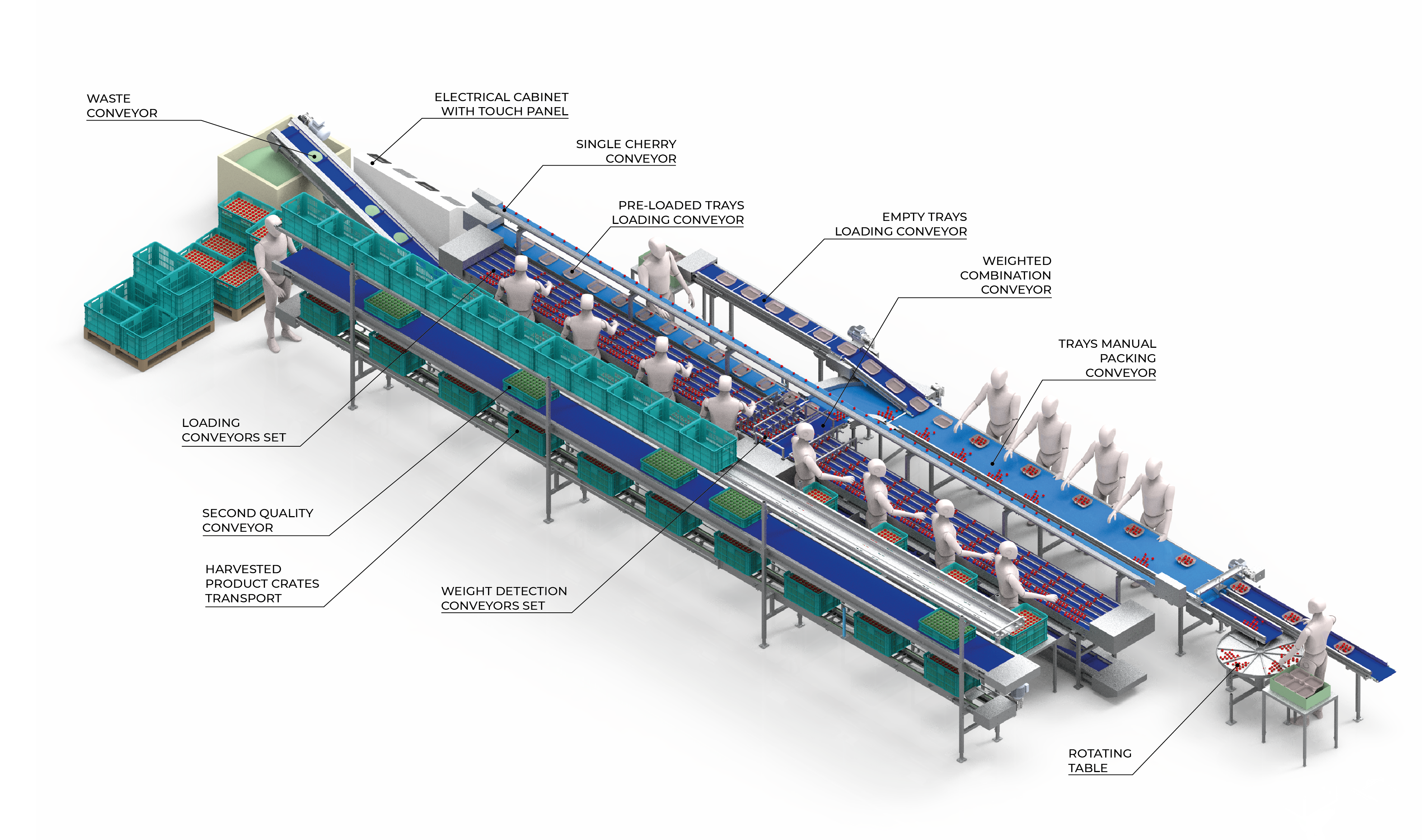

COMPLETE LINES FOR THE PROCESSING, SORTING AND PACKING OF YOUR VEGATABLES AND TUBERS

GUARANTEED MINIMUM WEIGHT TRAYS PROCESSING

LINE - THE NEW BULLTEC SOLUTION

A NEW SOLUTION by BULLTEC for the packing trays/baskets with GUARANTEED MINIMUM WEIGHT.

Thanks to the conveyor belt technology combined with a battery of seversal load cells, we are able to achieve the maximum optimization of weight combinations while minimizing excesses.

At the same time, the line configuration allows to keep the trays packing conveyor constantly feeded, for a continuous processing, reducing downtime to a minimum.

The last manual phase will also allow you to obtain the best

configuration for each tray.

A new approach that guarantees MAXIMUM VERSATILITY of use in the horticultural field.