- About us

- Company details

Claren Tools boasts more than 35 years of experience in the design and manufacturing of plastic injection moulds and die-casting technologies, employed in a wide variety of sectors, such as AUTOMOTIVE, DESIGN, FURNITURE, HOUSEHOLD APPLIANCES. Our main goal is granting our customers a complete and continous supporting service and a full assistance from the design of the product up to its final production.

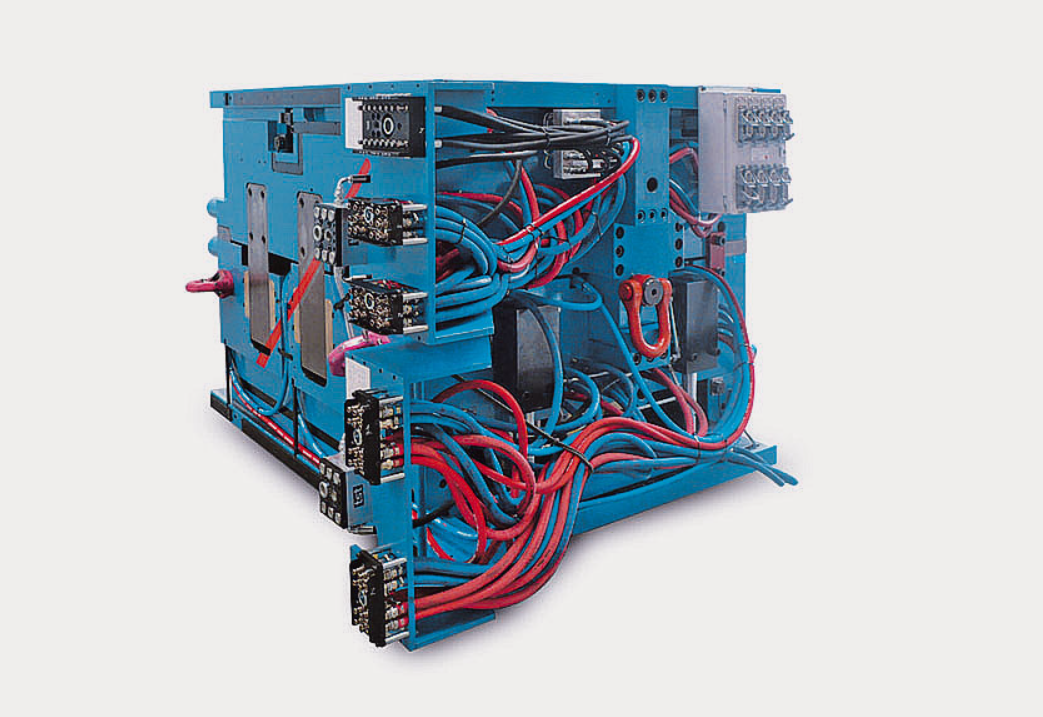

We are able to supply among the injection moulds aesthetic tools, two and three components tools, Stack tools, gas injection, Tandem, RHCM (by steam), Variotherm, and the die-casting moulds for aluminium.

In the past few years, thanks to important investments, we’ve widen our activity introducing a SERVICE ON DEMAND of special mechanic manufacturing processes, such as the DEEP DRILLING and the SPECIAL MILLING suitable to medium and big components.

Our company is also specialized in the NAUTICAL sector, thanks to the expertise in dealing with special materials such as staninless steel, aluminum, 17-4ph, 13-8ph, lead and titanium.

Year of establishment:

1987

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2025

Export turnover:

From 750.000 to 2.5 million Euro

Activities:

Manufacture of moulding boxes and moulds

Manufacture of other fabricated metal products nec

Manufacture of other various fabricated metal products nec

- Videos

- Catalogue

No videos uploaded

No documents uploaded

- Contact Information

- Business Proposals

Company:

CLAREN TOOLS SRL

Web site:

Address:

VIA DEI VETRAI 26/28/30

City:

Chiari (BS)

Zip Code:

25032

Social media:

Tag:

No business proposals uploaded

- Map

Injection Moulds

Thanks to the experience in the production of injection moulds we are now able to supply aesthetic tools, two and three components tools, Stack tools, gas injection, Tandem, RHCM (by steam), Variotherm oh a very high quality level.

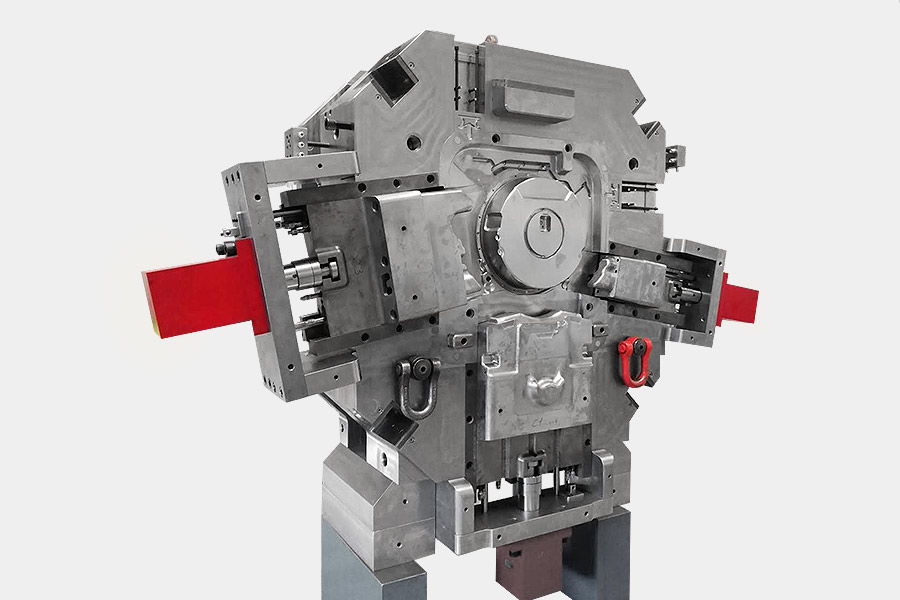

Die Casting Moulds

Our range of products is enriched by the Die Casting Moulds for aluminium.

CUSTOMIZED HIGH PRECISION MACHINING

Counting more than 35 CNC machines, our company is able to offer a complementary service on demand of special mechanical proceeses: the DEEP DRILLING and SPECIAL MILLING are particularly suitable for medium and big sizes components, to be employed in NAUTICS, AEROSPACE, and INDUSTRIAL SECTORS.