- About us

- Company details

RAN Innovation offers comprehensive digitalization services for industrial assets, leveraging advanced artificial intelligence.

We conduct surveys of any industrial asset using 3D laser scanner technology. The collected data is processed within a dedicated reference system, and with proprietary software developed by RAN Innovation, a digital twin of the tank is created—a parametric model containing detailed information about the asset’s real geometry, materials, and thicknesses.

Year of establishment:

2012

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2023

Export turnover:

Not available

Activities:

Project management activities related to integrated engineering

- Videos

- Catalogue

RAN AIM – THE ASSET INTEGRITY MANAGEMENT PLATFORM RAN Innovation has developed RAN AIM, a cloud-based Asset Integrity Management platform that enables you to monitor the reliability and efficiency of your assets over time, while ensuring health, safety, and environmental protection. RAN AIM centralizes all asset information, supporting advanced analyses for risk management, inspection prioritization, and corrective action planning.

No documents uploaded

- Contact Information

- Business Proposals

Company:

RAN INNOVATION S.R.L.

Web site:

Address:

VIALE DELLA PIRAMIDE CESTIA 1/C

City:

ROMA (RM)

Zip Code:

00153

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

ASSET DIGITALIZATION POWERED BY ARTIFICIAL INTELLIGENCE

We conduct surveys of any industrial asset using 3D laser scanner technology. The collected data is processed within a dedicated reference system, and with proprietary software developed by RAN Innovation, a digital twin of the tank is created—a parametric model containing detailed information about the asset’s real geometry, materials, and thicknesses.

Our artificial intelligence software module streamlines and accelerates the digitalization process. RAN Innovation’s algorithms automatically recognize industrial assets, defining their position and geometric characteristics with precision.

RAN AIM – THE ASSET INTEGRITY MANAGEMENT PLATFORM

RAN Innovation has developed RAN AIM, a cloud-based Asset Integrity Management platform that enables you to monitor the reliability and efficiency of your assets over time, while ensuring health, safety, and environmental protection.

RAN AIM centralizes all asset information, supporting advanced analyses for risk management, inspection prioritization, and corrective action planning.

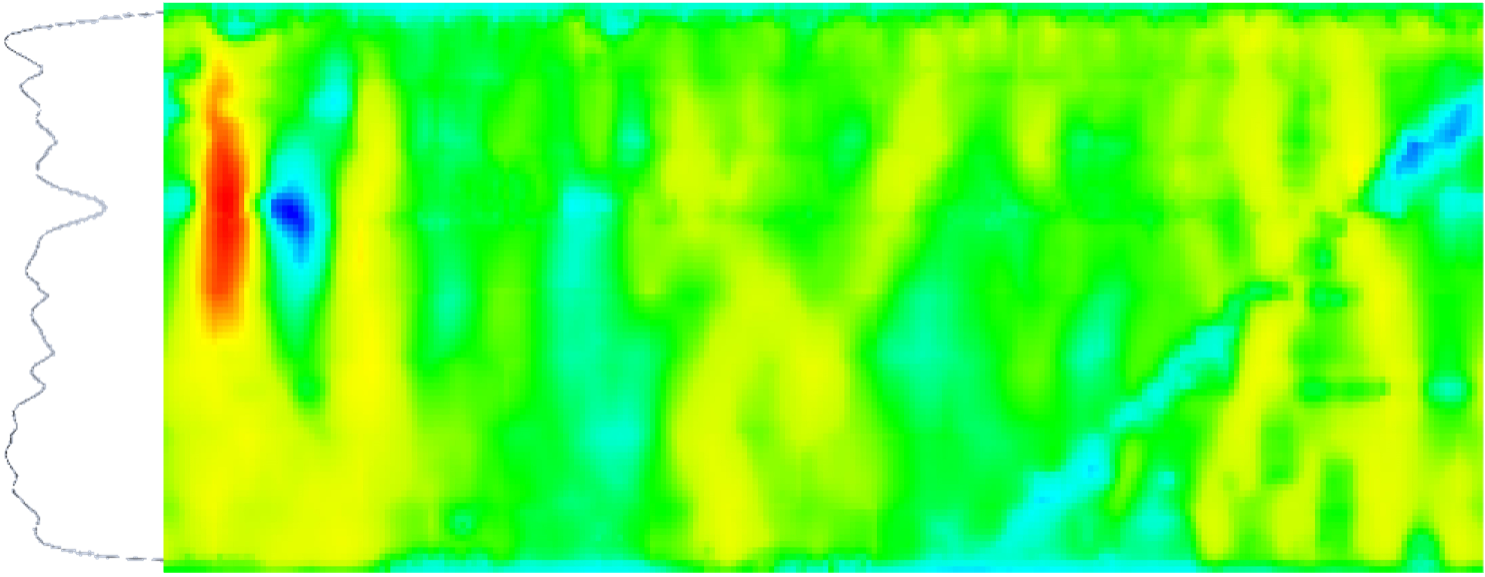

The platform displays real-time data from sensors installed on your assets. It is compatible with new or existing sensors of any brand or model, allowing configuration of multiple alarm levels and automatic reporting to the control room when preset thresholds are exceeded.

RAN AIM integrates a virtual reality 3D visualization module for digital twins, enabling remote review of technical characteristics, analyses, inspections, and interventions without on-site visits. Augmented reality features allow 3D asset information to be accessed directly on site.

REAL-TIME SETTLEMENT MONITORING OF INDUSTRIAL ASSETS

RAN Innovation provides continuous monitoring services for industrial assets, from initial survey and plant layout design to system supply and real-time monitoring platform integration.

Sensor data is transferred via a control unit to the RAN AIM platform, enabling real-time visualization and analysis. Our monitoring system is ATEX certified and suitable for installation in any industrial plant, including hazardous and explosive environments.

Multiple alarm levels can be configured for each sensor, and the control room is automatically notified when values exceed preset thresholds.

By choosing RAN Innovation, you gain a single, reliable partner offering durability, long-term reliability, and a wide range of specialist services to support data interpretation. This empowers you to make rapid, informed, and sustainable decisions.

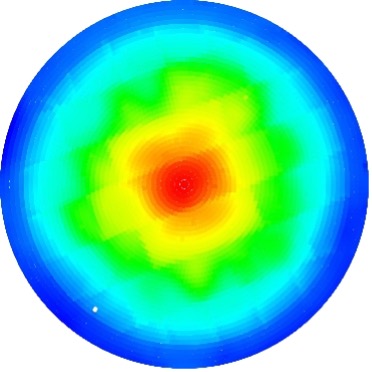

STORAGE TANK CALIBRATION

RAN Innovation offers calibration services for:

• Vertical axis atmospheric tanks (fixed or floating roof)

• Pressure tanks (underground or above ground)

Surveys are conducted using 3D laser scanning:

• Internal surveys for new or maintained tanks

• External surveys for tanks in operation (note: bottom geometry cannot be scanned in this case)

Data is processed to create a digital twin—a parametric model with detailed information about the tank’s real geometry, materials, and thicknesses.

From the digital twin, we generate calibration reports that consider:

• Actual geometry

• Effects of operating temperatures

• Effects of hydrostatic pressure (atmospheric tanks) or internal pressure (pressurized tanks)

• Tank element stiffness

Custom reports are available in compliance with international standards (ISO 7507, API, etc.) and can be exported in electronic formats (xlsx, csv, etc.), both full and reduced versions.

Our method eliminates the need for water to determine internal volumes, relying entirely on optical laser scanning for fast, repeatable, and highly reliable results.

RAN Innovation has decades of experience in tank calibration and is a trusted supplier to major Italian oil companies.

GEOMETRIC CHECK ACCORDING TO API 650 AND API 653

RAN Innovation provides geometric verification servicea for storage tanks:

• new tanks (API 650)

• existing tanks(API 653)

Checks include:

• out of plumbness check

• roundness check

• settlement evaluation

• floating roof traveling check

Surveys are conducted using 3D laser scanner:

• internal survey for new or maintained tanks

• external survey for tanks in operation, (bottom geometry cannot be scanned in this case)

Data is processed in a specific reference system and, using software exclusively owned by RAN Innovation, the digital twin of the tank is created, i.e. a parametric model that contains detailed information relating to the real geometry, materials and thicknesses of the tank itself.

The digital twin enables comprehensive calibration reports, considering:

• Effective geometry

• Tank axis rotations

• Shell course alignment (internal, axial, or external)

Final reports summarize all checks and provide recommendations for resolving any identified issues. For floating roof travel, we analyze the gap between the roof and tank shell at each reference height, assessing all geometrically admissible configurations.