- About us

- Company details

P.G. GROUP SRL, formerly known as Polese Automation, stands at the forefront of brush machinery innovation, focusing on the research and engineering of advanced solutions for various types of paint brush production. With a legacy of excellence and a future driven by innovation, we are committed to delivering unparalleled service and technology in the brush machinery sector.

Our expertise encompasses the design, construction, maintenance, and installation of a comprehensive range of paintbrush machinery solutions, from individual machines to complete plant setups.

Our portfolio includes:

- Automated lines for flat and round paint brushes

- Paint brush machine

- Paint brush making machines

- Paint brush cleaning machines

- Epoxy mixing and dispensing machines

- Industrial Automation

- Precision Industrial Robots - SCARA

- Spare parts for paintbrush machinery

- Maintenance and Installation services for paintbrush machinery

- Retrofitting and Upgrade services for existing paintbrush machinery

We believe in the power of technology to transform production processes, making them more efficient, reliable, and cost-effective. Our commitment to innovation is matched by our dedication to customer service, ensuring that each client receives personalized solutions tailored to their specific needs.

Stay connected with us through our media channels for the latest updates and insights into brush production technology:

- Website: https://thepgg.com/

- Instagram: https://www.instagram.com/pggroupsrl/

- LinkedIn: https://www.linkedin.com/company/pg-group-srl/

- Phone: +39 043 477 470

For inquiries, assistance, or to discover how our technologies can benefit your production line, reach out to us at +39 (376) 207-7510 (also available on WhatsApp) or via email at alex@pg-group.it, info@pg-group.it.

P.G. GROUP SRL is your partners in innovation, driving your brush production towards greater success.

Year of establishment:

2006

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2024

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of machinery and equipment nec

Manufacture of other general-purpose machinery n.e.c

Manufacture of distilling or rectifying plant for petroleum refineries and chemical industries

Manufacture of packing and wrapping machinery

Manufacture of other special-purpose machinery

Manufacture of all other various special-purpose machinery nec

- Videos

- Catalogue

MAP10 - Automatic assembling machine for producing paint brush heads with the precision of automatic insertion of 1 or 2 wedges. Production Range: - Ferrules: From 3/4" to 4" in width, 9 to 25 mm in thickness. – Material Compatibility: All types of bristle. Why Choose MAP10? - Compact Size: Just 12.25 sq. meters. - Low Consumption: 400 liters per min. of air, 1.2 kW power. - High Production Rate: 800 - 1000 Pcs/h. Invest in quality European equipment from PG GROUP. Invest in the growth and profitability of your company. Leave us a message: Corporate Business WhatsApp number: +39 (376) 207-7510 alex@pg-group.it or info@pg-group.it Visit our website: https://thepgg.com/ #manufacturing #paintbrush #automation #PGGROUP #investment #businessgrowth #efficiency

UNIVERSAL PRINTING AND WRAPPING MACHINE The new model MAP1-BTE proposed in a new version to satisfy completely productions capacity with possibility of using ecological materials, replaces the previous MAP1-BTE can be suppled as wrapping machine only. Completely automatic, designed to wrap brush heads and stamp handles without any intervention of operator. Can operate in automatic conjunction with any vendor operating line for finished products. Production range: - Flat brushes from 1/2” to 4” - Round brushes with diameter from 10 mm to 55 mm - With plastic or metal ferrules Contact us now at alex@pg-group.it or +39 376 207 7510 (WhatsApp). https://thepgg.com/

Automation line and machinery P.G. GROUP SRL - Automation lines and paint brush production machinery company from Italy. Follow us to stay tuned on modern machinery news. For inquiries on pricing and production times, visit us at https://thepgg.com or contact alex@pg-group.it, info@pg-group.it

Automatic line for producing flat paint brushes ranging from 1 to 4 inches - a pivotal stage in the production cycle that showcases the synergy of precision engineering and innovative technology. Featured Equipment: 1. MAP4 - Automatic feed and trimming machine with a brush loader. 2. MAP3 - Universal cleaning machine. 3. MAP1B - Automatic shrink-wrap packaging machine (with an optional labeling system). 4. MAP9 - Tampon-pad printing machine. Utilizing P.G. GROUP SRL's manufacturing equipment not only elevates the quality and volume of your production but also minimizes operational costs, saving resources and boosting your profits. Enjoy fully automatic operations, consistent product quality, low operational costs, and attractive equipment pricing. For inquiries about acquiring paint brush manufacturing equipment, submit your requests via the contact form on our website https://thepgg.com or through WhatsApp at +39 376 207 7510

AUTOMATIC GLUE LINE MAP 15 is a highly advanced automatic positioner specifically designed to optimize the glue line process for flat paint brush heads. It offers seamless integration with MAP 10/B Linear, MAP 10/Small, or other machines, effortlessly transferring and positioning the brush heads for precise and automated glue insertion.

- Contact Information

- Business Proposals

Company:

P.G. GROUP S.R.L.

Web site:

Address:

VIA COL DE RUST 9/A

City:

SARONE CANEVA (PN)

Zip Code:

33070

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

MAP1-BTE - Universal Automatic Printing and Wrapping Machine

UNIVERSAL PRINTING AND WRAPPING MACHINE

The new model MAP1-BTE proposed in a new version to satisfy completely productions capacity with possibility of using ecological materials, replaces the previous MAP1-BTE can be suppled as wrapping machine only.

Completely automatic, designed to wrap brush heads and stamp handles without any intervention of operator.

Can operate in automatic conjunction with any vendor operating line for finished products.

Production range:

- Flat brushes from 1/2” to 4”

- Round brushes with diameter from 10 mm to 55 mm

- With plastic or metal ferrules

Processing phases:

Loading unit

Brush collection

Wrapping with new ecological film or other types of film

Film sealing

Trimming the wallet

Film heat-shrinking

Unload for printing

Printing with ink-pad

Unloading unit

Main features:

Electronic control with PLC

Remote assistance (optional) available with wired or Wi-Fi connection

The constructive system and materials used, tested in more than 200 working plants, have demonstrated endurance, efficiency, and simplicity in maintenance

Technical specification:

Operators: 1

Production: 800 / 1200 Pcs/h

Patching Material: single-fold heat-shrinkable film

Film thickness: 10 to 25 microns

Film width: 100 to 150 mm

Power Supply Voltage: 230/400 VAC 50/60 Hz

Power Consumption: 2.6 kW/h

Setup Time: < 5 - 10 minutes

Air Consumption: 500 l/min at 6 bar

Dimensions: LxW = 3100 x 2400, H = 1500 mm

Weight: 500 kg

->> Ideal for businesses aiming to increase their production efficiency while maintaining a commitment to sustainability.

MAP10-LB - Automatic paintbrush Head Assembling Machine

AUTOMATIC HEAD ASSEMBLING MACHINE MAP10-LB WITH NEW BELT TRANSPORT SYSTEM

Model MAP10-LB , is an automatic assembling machine for production of brush heads with automatic insertion of 1,2 or3 wedges. (3 wedge optional)

It is designed to work in conjunction with an automatic system for ferrules loading MAP16, glue insertion in finished heads (MAP31 or MAP15)

Production range:

Ferrules range: from 3/4" to 4" in width and from 7 to 25 mm in thickness

Material: Natural, synthetic or mixed filaments

Processing phases:

Feeding of both bristles

Insertion of bristles in ferrules

Insertion of wedges

Alignment of bristles by vibration

Setting of bristles for desired height

Transfer of finished heads

Key features:

Electronic control with PLC and HMI.

Remote assistance (optional) available with wired or Wi-Fi connection.

Ready for Industry 4.0 (Optional)

Constructive system and the materials used, have demonstrated endurance, efficiency and ease of maintenance

Technical specification:

Operators: 1

Production: 900 - 1500 Pcs/h

Material: Natural, synthetic or mixed filaments, All types of bristle

Power Supply: 230/380 VAC 50/60 Hz

Setup Time: < 20 minutes

Air Consumption: 500 l/min at 6 bar

LxWxH: 4700x2300x1900 mm

Weight: 750 kg

->> Ideal for businesses aiming to increase their production efficiency while maintaining a commitment to sustainability and relatively low initial costs.

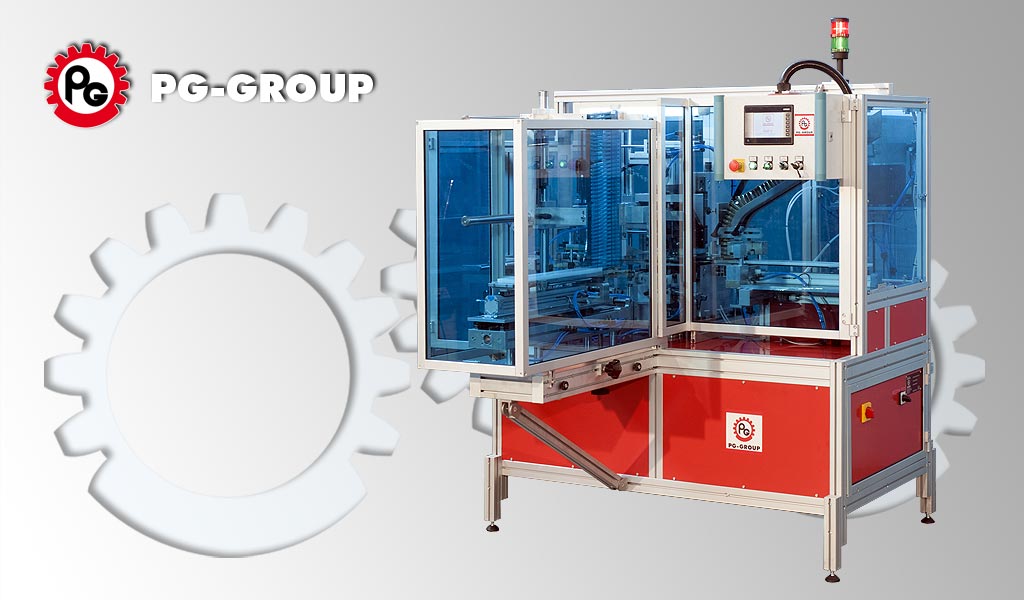

MAP10-S/12 stations - Fully automatic paintbrush head-making machine

AUTOMATIC HEAD ASSEMBLING MACHINE

Model MAP10-S/12 stations, is an automatic assembling machine for production of brush heads with automatic insertion of 1 or 2 wedges.

It is designed to work stand alone or in conjunction with an automatic system for glue insertion in finished heads.

Can operate in automatic conjunction with any operating Line for finished products.

Production range:

Ferrules range: from 1" to 4" in width and from 9 to 25 mm in thickness.

Material: All types of bristle.

Processing phases:

Feeding of bristles

Insertion of bristles in ferrules

Insertion of wedges

Alignment of bristles by vibration

Setting of bristles for desired height

Transfer of finished heads

Key features:

Electronic control with PLC and HMI

Remote assistance available with wired or Wi-Fi connection

Ready for Industry 4.0

Constructive system and the materials used, have demonstrated endurance, efficiency and ease of maintenance

Technical specification:

Operators: 1

Production: 900 - 1200 Pcs/h

Material: All types of bristle

Power Supply: 230/380 VAC 50/60 Hz

Setup Time: < 20 minutes

Air Consumption: 500 l/min at 6 bar

LxWxH: 2700x2600x2200 mm

Weight: 750 kg

->> Ideal for businesses aiming to increase their production efficiency while maintaining a commitment to sustainability and relatively low initial costs.

MAP6-E - Fully Automatic Assembling Machine for paint Brushes

AUTOMATIC ASSEMBLING MACHINE FOR BRUSHES - MAP6

The MAP6 is a high-performance paintbrush assembling machine with nailing and trimming designed for efficient brush assembly.

- It features a standard model with 4 nails, and the option to have 6 nails upon request. The machine securely inserts the handle onto the brush head, nails it in place, and trims the bristles with precision. For enhanced versatility, it can be equipped with two trimming units

- With its impressive production speed and quick set-up time, the MAP6 is suitable for both large-scale and small-scale production runs. It can be seamlessly combined with the MAP3 flirting machine or any other compatible flirting machine. The machine allows for swift size changes, ensuring flexibility in production

Key features:

Operating the MAP6 requires only one operator, and there is an option for automatic handle loading using the MAP16. The machine incorporates automatic control for nail presence, independently monitoring each nail. If a nail is missing, the machine automatically stops and indicates the issue

The MAP6 is equipped with electronic control featuring a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface). Additionally, it offers the option of remote assistance, accessible through wired or Wi-Fi connections, for prompt support and troubleshooting

The construction system and materials utilized in the MAP6 have been extensively tested in over 200 working plants, demonstrating exceptional durability, efficiency, and ease of maintenance

Fast size changing

Technical specification:

Production rate: 1200 pcs/h

Product Range: ferrules from 20 to 100 mm, handle up to 400 mm (all type of handles)

Nail dimension: diameter 1.2 - 1.4 mm, head 2.4 - 2.8 mm, length 7 - 9 mm

Power Supply Voltage: 230/400 VAC 50/60 Hz

Air Consumption: 400 l/min at 6 bar

LxWxH: 1700x1800x1700 mm

Weight: 540 kg

--> Experience the future of brush manufacturing with our 4 nails semi-automatic nailing machine. Streamline your production process, achieve remarkable quality, and stay ahead of the competition.

--> Contact us today to learn more about this exceptional machine and how it can transform your business.

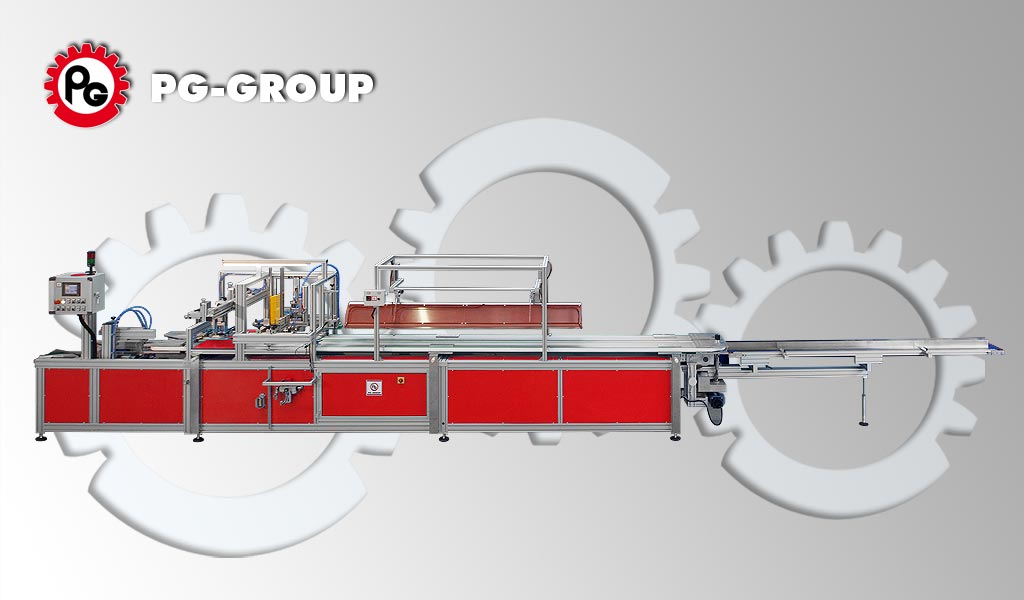

MAP31 - Automatic Glue Line with Brush Handles Loader

AUTOMATIC GLUE LINE WITH BRUSH HANDLES LOADER - MAP31

Model MAP31 from P.G GROUP Srl is an innovative automatic positioner and glue line system designed for transferring and processing flat paint brush heads. It efficiently handles heads from MAP 10 or from other manufacturers, aligning them for automatic epoxy glue insertion. This system is capable of processing brush heads with a thickness ranging from 9 to 25 mm and a width from 20 to 150 mm, making it versatile for a variety of brush sizes.

Production Range:

Handles brushes from 9 to 25 mm in thickness and from 20 to 150 mm in width.

Compatible with all types of brush handles.

Processing Phases:

Accurate positioning of heads in the clamp

An electronic eye ensures the bristle is correctly placed in the brush head

Bristle pusher adjusts to the required length

Resin distribution over bristles

Smooth progression of glued heads through the heating tunnel

Optional automatic handle loading enhances efficiency

Main Features:

Advanced electronic control with PLC for precise operations.

Constructive system and high-quality materials ensure durability, high efficiency, and ease of maintenance.

Remote assistance capabilities via wired or Wi-Fi connection, ready for Industry 4.0 standards.

Technical Specification:

Operators needed: 1 for handling

Production capacity: 800 - 1400 Pcs/h

Power Supply Voltage: 230/400 VAC 50/60 Hz

Air Consumption: 100 l/min at 6 bar

Dimensions (LxWxH): 10000x1100x1750 mm

Weight: 1150 kg

--> Ideal for businesses looking to enhance their production capabilities with automated efficiency, the MAP31 system offers a high-tech solution for brush head gluing and assembly. This system not only boosts production rates but also ensures consistent quality and reduced labor costs, aligning with modern sustainability and efficiency goals