- About us

- Company details

FSC Project is a company specializing in industrial automation, able to support you with a 360-degree approach: from design to construction, from installation to after-sales service.

We design and build tailor-made machines and systems developed according to your specific needs. We operate in various sectors: food, automotive, eyewear, defense, and plastic molding, offering broad and consolidated cross-sector know-how.

Automation provides significant advantages: process optimization, cost reduction, error reduction and 100% quality control. We make these benefits tangible by calculating the return on investment, helping you make well-informed decisions as possible.

What sets us apart is our ability to offer truly customized, tailor-made solutions: we do not limit ourselves to building the requested machine, but adapt it perfectly to your specific situation, taking into account the critical aspects like footprint, ergonomics, operating cycle, to ensure the best possible result.

In addition to working on a project basis, we also provide support in Research & Development: if you have a project but are unsure of its feasibility or lack specific skills, we guide you with a step-by-step approach, defining the operational phases together and developing feasibility checks and prototypes along the way. This method allows you to validate solutions during development and minimize investment risk.

Year of establishment:

2018

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2024

Export turnover:

Less than 75.000 Euro

Activities:

Manufacture of machinery and equipment nec

Manufacture of other general-purpose machinery

Manufacture of other machine tools

Manufacture of machinery for food, beverage and tobacco processing

Manufacture of plastics and rubber machinery

- Videos

- Catalogue

This corporate video presents our identity. FSC stands for Fiorani Synergetic Connections. We design and build machinery driven by passion and by the synergy between people, technologies, and skills. Passion and synergy are our pillars; without them, we would be just another company.

This video tells the bond with our territory. We are based in Acqualagna, a small town known worldwide as the truffle capital. We wanted to be part of this tradition, helping to keep it alive and strong. That’s why we chose to combine innovation and tradition, listening to the needs of those who work with this precious product every day and turning them into solutions that respect its value. The video shows the operation of the truffle sorting machine that separates truffles by size. Another solution dedicated to the truffle sector is the truffle washing machine.

- Contact Information

- Business Proposals

Company:

FSC PROJECT SRL

Web site:

Address:

Via dell'Agricoltura 1E

City:

Acqualagna (PU)

Zip Code:

61041

Social media:

Tag:

- Map

Box forming machine

The box forming machine is a compact, space-saving solution designed to significantly reduce intralogistics costs.

The customer already had an efficient forming machine, but its large footprint forced operators to frequently move boxes from one warehouse to another. A new compact solution was therefore developed, fully integrated into the existing operational line with a working pace synchronized to the operator’s rhythm, preventing material buildup and optimizing the available space.

The machine can be customized according to the type of box and the required operating speed.

Web site

https://youtu.be/NEseOsiyyEM

Machine for assembling breechblock components

Machine for precise assembly of breechblock components: retaining pin, check valve, lever.

3D Printer

The 3D pasta printer, based on the principle of additive manufacturing, enables the three-dimensional creation of the product by adding the dough layer by layer, allowing for complex and customized shapes.

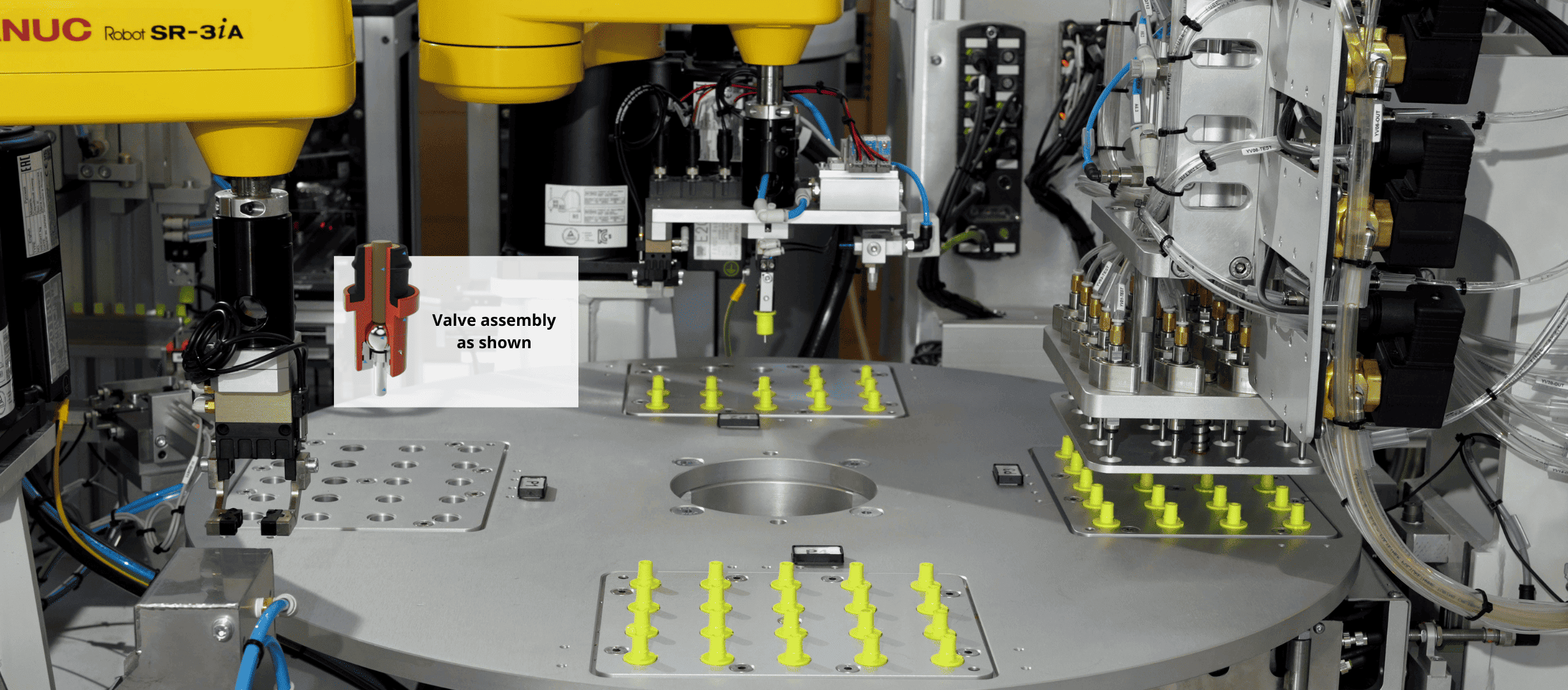

Rotary table for assembly and testing

The rotary table allows a continuous production flow and ensures fully automatic operation, increasing efficiency and productivity.

The machine is designed for the assembly and testing of valves intended for chicken drinkers.

This is an example of an assembly and testing operation that can be customized according to your specific requirements.

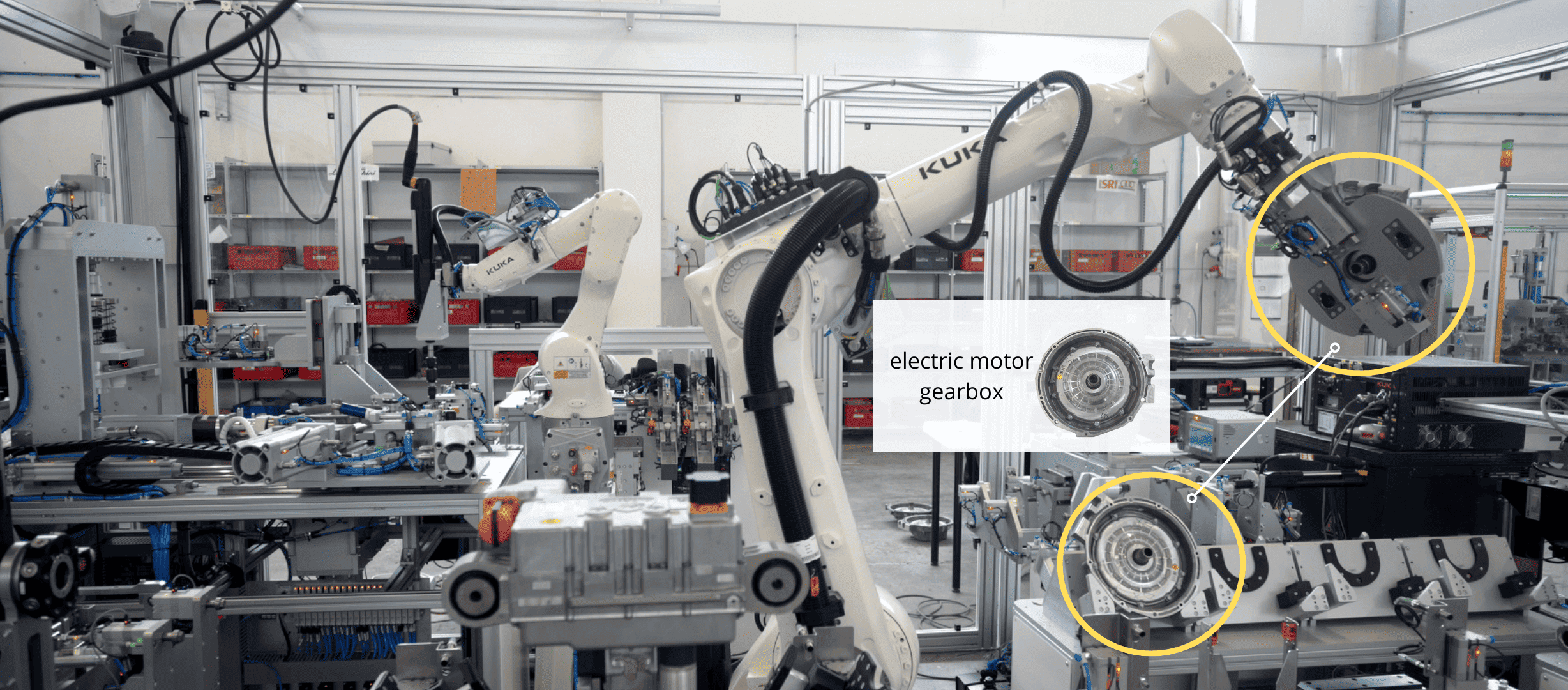

Gearbox automatic assembly

It is a robotic cell that transformed a fully manual process into a fully automated solution for the assembly and testing of electric motor gearbox.

This automation was implemented to reduce the margin of error, ensure precise screwdriving control, provide traceability, and integrate testing.