- About us

- Company details

ergolines is a market leader company in stirring technology, providing customized EMSs for continuous casting machines to produce billets, blooms, rounds, BB and slabs.

Besides, the EMS family includes stirrers for electric furnaces, ladle furnaces, Al furnaces and non ferrous casters.

Alongside EMS, ergolines provides high efficient mould powder feeding systems for any kind of casting products also fitted with powder thickness detectors for the closed-loop control. Besides, ergolines’ product range includes a set of technological sensors for mould level and powder thickness detection as well as standard devices for the preventive maintenance of EMS, ladle slag carry-over, mould oscillating monitoring.

All ergolines products are designed to achieve the highest standard in molten metal quality and production efficiency.

We export to over 50 countries, having excellent references worldwide.

Year of establishment:

1998

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2019

Export turnover:

0

Activities:

Manufacture of basic metals

Manufacture of basic iron and steel and of ferro-alloys

Manufacture of machinery for metallurgy

Repair, maintenance and installation of machinery and equipment

Installation of measurement and testing equipment

Wholesale of computers, computer peripheral equipment and software

Scientific research and development

Other research and experimental development on natural sciences and engineering nec

- Videos

- Catalogue

ELECTROMAGNETIC STIRRER VIDEO

ULTRASONIC TEMPERATURE MAP

POWDER THICKNESS MEASUREMENT AND CONTROL SYSTEM

STIRRER FOR CONTINUOUS CASTING OF COPPER ALLOYS

ALUMINUM FURNACE STIRRER

No documents uploaded

- Contact Information

- Business Proposals

Company:

ERGOLINES LAB - SOCIETA' A RESPONSABILITA' LIMITATA

Web site:

Address:

PADRICIANO 99

City:

PADRICIANO (TS) TRIESTE (TS)

Zip Code:

34016

Social media:

Tag:

No business proposals uploaded

- Map

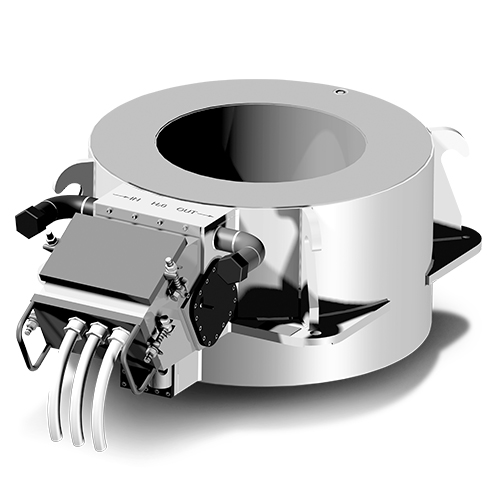

EMS

The electromagnetic stirrer is one of our core products and it is used in the continuous casting process to improve the product quality and to increase steel production. Contrary to the main market offer ergolines offers taylor made solutions to achieve the highest standard in molten metal quality and production efficiency.

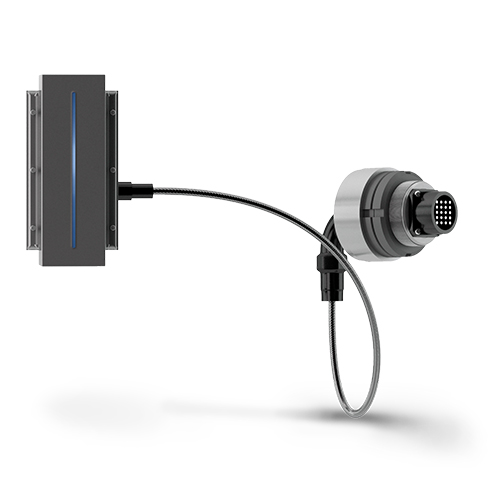

FLUX FEEDER + POWDER THICKNESS MEASUREMENT AND CONTROL SYSTEM

Mould powder feeder is a device useful to automate the powder feeding on the liquid bath into the mould. It can be used in combination with ergolines' ultrasonic level detector (ULD) , an innovative sensor which measures in real-time the mould powder thickness, or with ergolines' IPD, a new generation poeder diffuser equipped with an optical system.

ULD& UT-MAP

The ultrasonic level detector is an innovative sturdy system applicable to billets, blooms and Beam Blanks CCMs for measuring and controlling the steel level in the mould.

It enables significant cost saving and fast return on investment.

In addition to information regarding the steel level, the data provided by ULD sensor can be used by UT-MAP, a specific software designed for the real time thermal mapping of the copper mould.

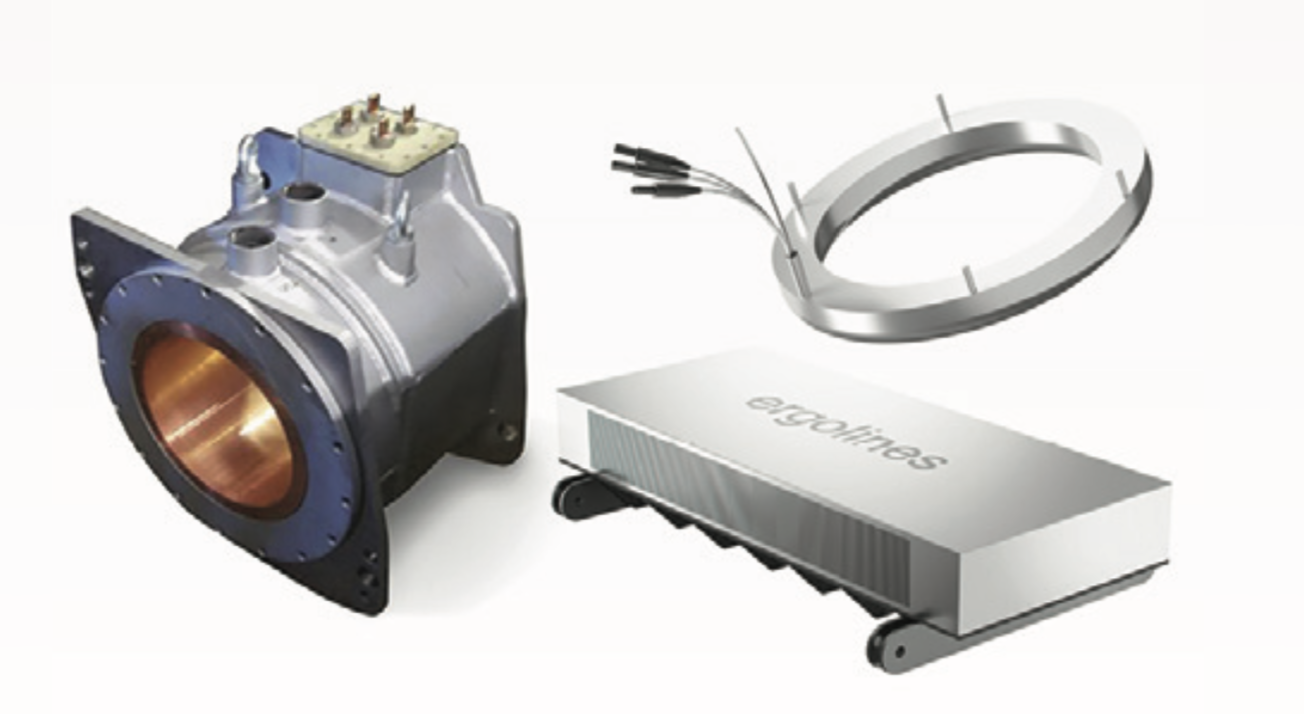

EMS FOR NON FERROUS ALLOYS

Besides electromagnetic stirrers for continuous casting, ergolines offers a wide range of stirrer for non ferrous alloys such as aluminum, brass and copper alloys