- About us

- Company details

Zanasi S.r.l. is the sole italian company which manufactures industrial ink-jet printing systems for CIJ (Continuous Ink Jet) and DOD (Drop On Demand) technologies.

Our company has been growing steadily since its establishment in 1978 and is now able to rival with the major competitors on the global market and to offer to its customers a first-class service, thanks to the support provided by a widespread network of highly qualified distributors. Besides that, continuous investments into research and development have allowed Zanasi printing systems to reach superb quality levels.

The headquarters are in Sassuolo (Modena). Zanasi has also a commercial branch in Milan, in Rome, in USA (Minneapolis) and in China (Guangzhou and Beijing).

Year of establishment:

1982

Number of employees:

FROM 50 TO 99 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2023

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of machinery and equipment nec

Manufacture of packing and wrapping machinery

Manufacture of printing and bookbinding machines

- Contact Information

- Business Proposals

Company:

ZANASI S.R.L.

Web site:

Address:

VIA MARCHE 10

City:

SASSUOLO (MO)

Zip Code:

41049

Tag:

No business proposals uploaded

- Map

CIJ.Z

Inkjet printer for coding on primary and or secondary packaging.

High Definition Ink-jet printer Z640

The high-resolution system designed to meet the traceability and communication needs of secondary packaging. The Z640PLUS e-JET system uses patented high contrast inks that allow you to reproduce in high definition any text, barcode or graphic on porous and non-porous surfaces for the total branding of the product.

The system is equipped with a stand-alone console, which can manage a maximum of 2 Graph e-JET print heads with a working range up to 50 mm (2 ") or up to 102 mm (4"), to adapt to the most different printing areas and marking the product on one or both sides, of one or two independent production lines.

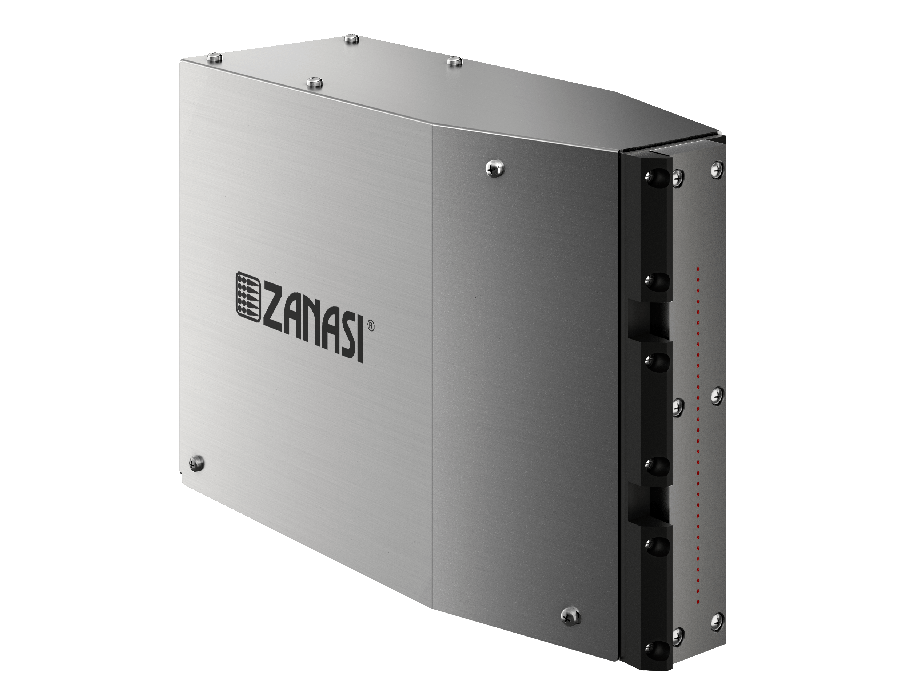

Large character marking Z402 DOD

Z402 is a system designed to ensure uniform and constant performance even in particularly difficult production environments. It can control up to 2 NZ heads, 1 16 dot head or 2 7 dot heads, with a series of fonts and matrices essential to obtain high quality prints with up to 2 lines and a height between 5 and 60 mm, on the side, on the top and on the bottom of the packaging.

The constructive reliability of the system is ensured by the compact and solid stainless steel structure, equipped with internal ventilation and a high IP protection to withstand humidity, dust and high temperatures.

POWERED BY

The modern 7” colour display with touch screen allows to create messages, images and shapes using an intuitive graphic editor, facilitates data entry and the selection of printing processes. The interaction with the system is guided by the revolutionary Orkestra management software with customisable user interface for each operator. NZ printheads allow to print alphanumeric texts, barcodes and logos with a maximum height of 190 mm on absorbent (paper, cardboard, wood), semi-absorbent and non-absorbent surfaces (PVC, polyester, rubber, aluminium, steel, glass, ceramic) thanks to the use of a wide range of inks.

Large character marking Z408 DOD

The wide range of fast-drying, high-adhesion water-, alcohol- and solvent-based inks allows Z408 to print high quality texts, barcodes and logos on any type of surface. Particularly suitable to mark paper and plastic bags, cardboard packaging, wooden profiles, laminates and sheets, panels, construction and extruded materials, the system guarantees efficiency and reliability in numerous applications and sectors, such as metallurgical, extrusion, construction, petrochemical, ceramic, cement, food, livestock and automotive.

Thermal Ink-Jet Z4

The wide range of high-contrast solvent-based, pigmented, non-pigmented and food grade inks, available in various colours in smart ink cartridges, makes the Z4 coding solution suitable for the most varied materials, both with porous and non-porous surfaces.

TJET printheads

The flexibility of the range, with a maximum height of 50,8 mm (2”), allows to print alphanumeric texts, logos, 2D barcodes and QR codes, on primary packaging, secondary packaging and multipacks, with a porous or non-porous surface, such as paper, cardboard, aluminium, flexible film, plasticised and painted boxes, labels and many others.