- About us

- Company details

Carminati morse is a long-standing company internationally known for its precision vices. Since its establishment in 1975, it has continued refining its unique construction techniques, which guarantee exceptional results in terms of precision and duration. The company’s flagship is its wide range of clamping and gripping solutions, which can fulfill every need. The latest products Carminati Morse has developed are meant to solve problems related to CNC machining centers.

The product range offered by CARMINATI MORSE encompasses a vast array of vices including the following types:

• Standard vices

• Auto centered vices

• Clamping vices

• Blocking mechanical vises

CARMINATI MORSE SNC is member of CAMSER - Consortium for the Internazionalisation - www.camser.com

Year of establishment:

1975

Number of employees:

UP TO 2 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2018

Export turnover:

From 75.000 to 250.000 Euro

Activities:

MANUFACTURING OF METAL PRODUCTS (EXCLUDING MACHINERY AND EQUIPMENT)

Manufacturing of tools

Manufacturing of tools for manual use; interchangeable parts for machine tools

MANUFACTURING OF MACHINERY TO FORM METALS AND OTHER MACHINE TOOLS

- Contact Information

- Business Proposals

Company:

CARMINATI MORSE SNC DI CARMINATI VINCENZO & C.

Web site:

Address:

VIA BROLO 28

City:

BRESCIA (BS)

Zip Code:

25136

Tag:

No business proposals uploaded

- Map

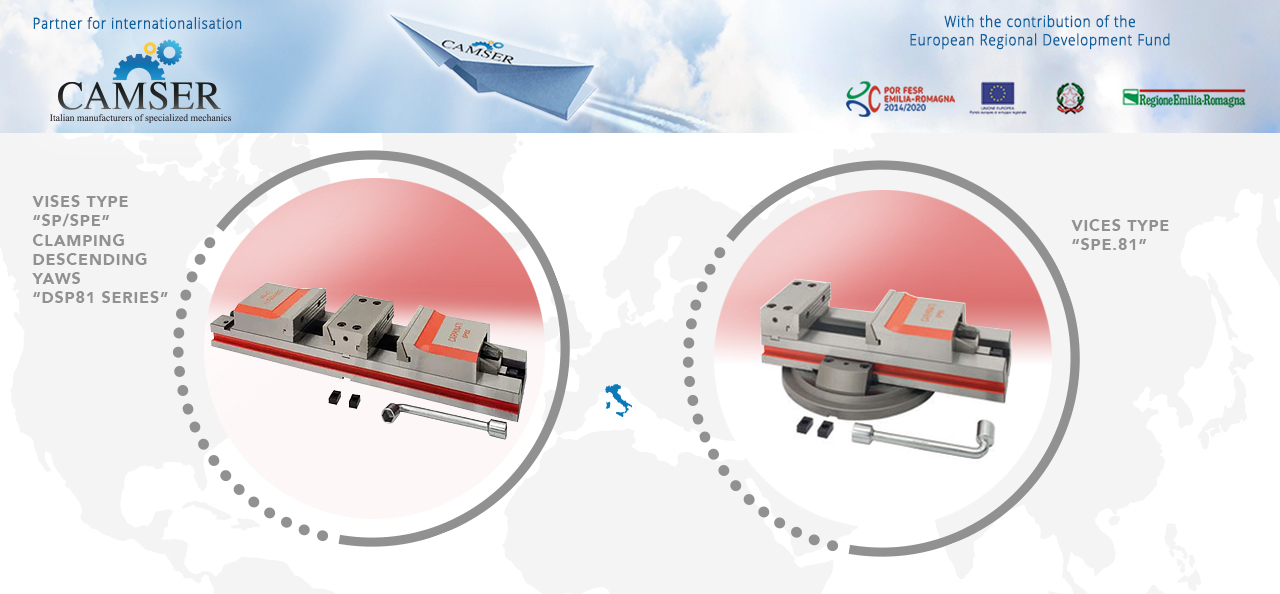

Vises type SP/SPE clamping descending yaws with mechanical/hidraulics/oleopneumatics

High precision SP81 vices are made of hardened nickel steel. They are the show-piece of the Carminati production. For holding piece with difficult shapes, the vice is fitted with optional components providing various solutions.

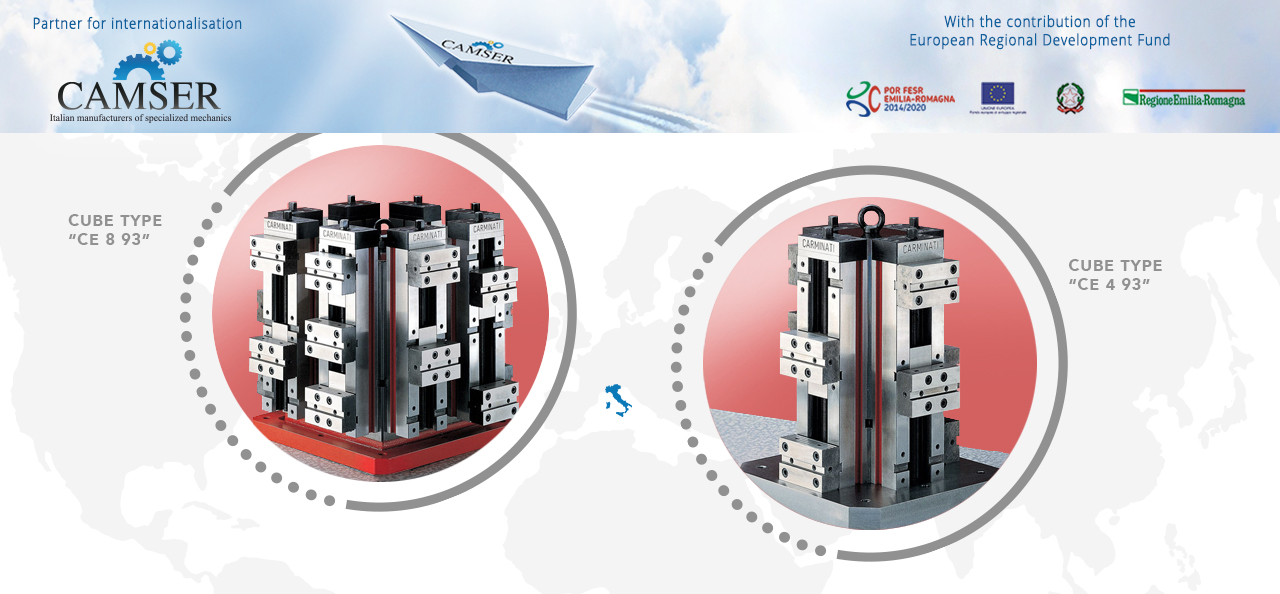

Standard series Vices and cubes

The cube type is the ideal solution projected by CARMINATI for using contemporaneously 4 vices of the series Europe 99 vertically. Dimensional and compact, assure maximum rigidity to exploit at best the power of C.N. Buildt in stabilized steel, rectified with centesimal tolerance further max precision.

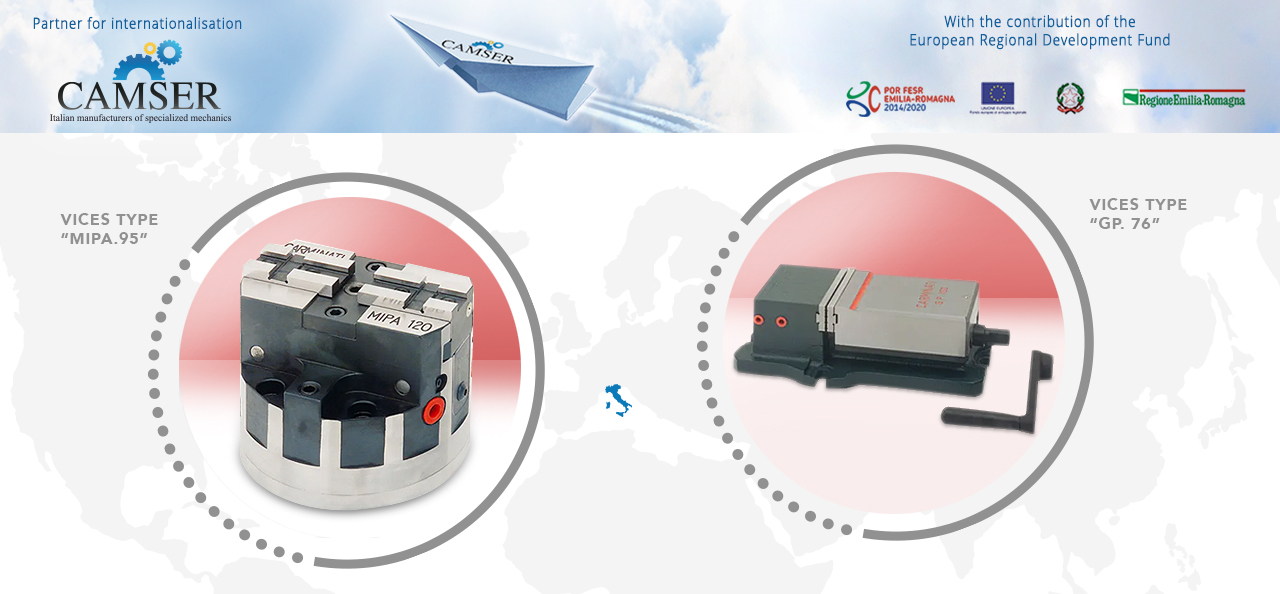

Pneumatic vice type

The vice type MIPA. 95 is the ideal too to block pieces on rotating table machines in their various stationary positions, for mechanical zork, assemblage or movement of pieces.

Entirely buildt in chromium nickel steel, hardened in 58 HRC, rectified, assure max precision, perfect function, unlimited duration. Inserting jaws in proper slides, sited in vice bogie, it s possible to block pieces of various form.

Function with air or oil until 20 BAR. Buildt in three models to satisfy various request.

Vises Europe auto centred locking mechanical/oleopneumatics, single, double and self centering vises

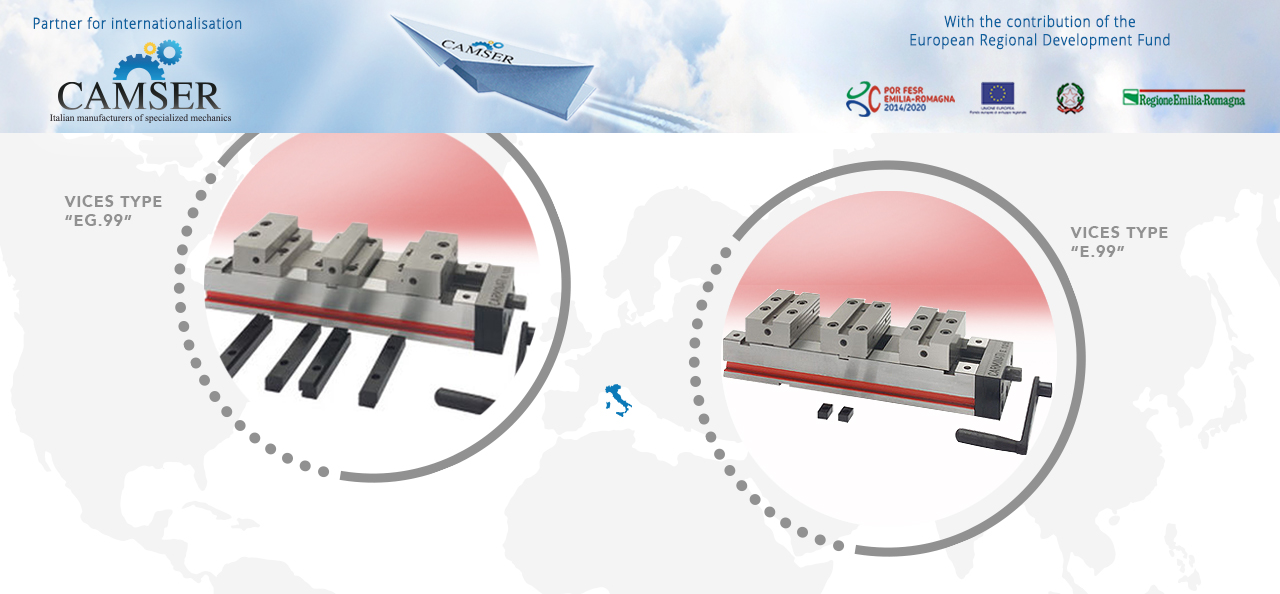

The Europa type is a high precision, modular vice. It has a mechanicalmechanical locking facility, and a covered manoeuvring screw. It can be assembled in three different solutions according to locking requirements.

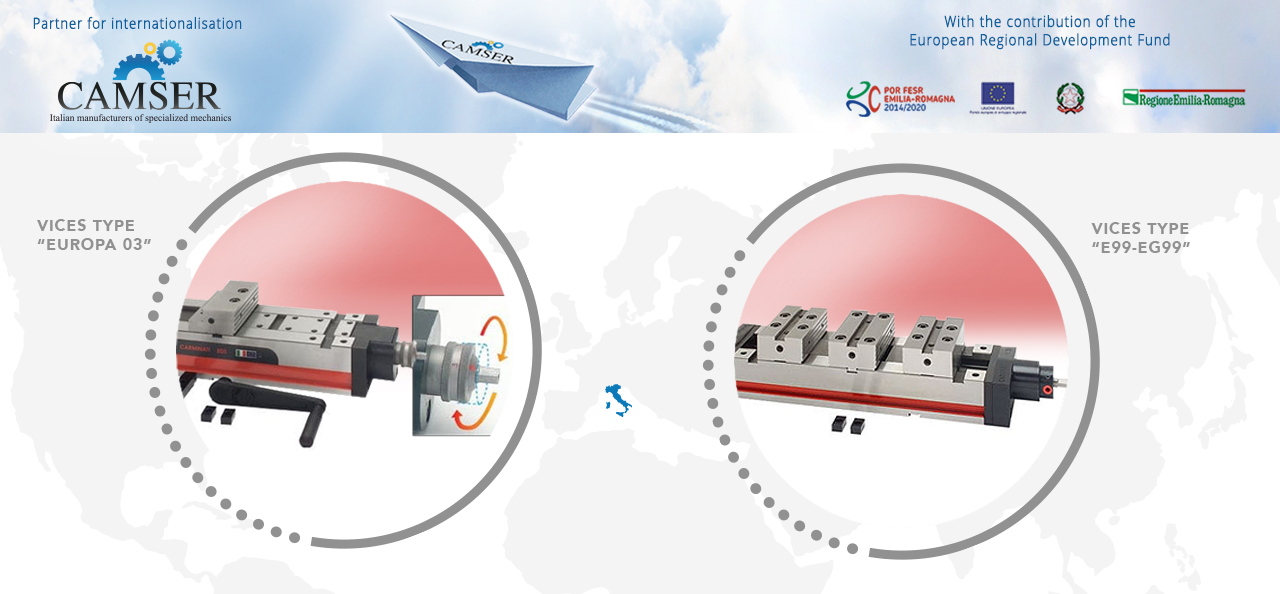

Machine tool vise Europa 03 series / E99-EG99

The Europa 03 type is a high precision, modular vice. It has a mechanicalmechanical locking facility, and a covered manoeuvring screw. It can be assembled in three different solutions according to locking requirements:

- TYPE ED03: DOUBLE SELF-LOCKING VICE with facility for closing the two pieces simultaneously, with tolerance up to 2mm.

- TYPE ES03: SINGLE VICE WITH THRUST-LOCKING

- TYPE ET03: SINGLE VICE WITH PULL-LOCKING.

The covered spindle screw and use of chromium-nickel materials hardened to 58 HRC, assure almost unlimited long-life. The vice, ground on all surfaces., can be used onplane or squared with a tolerance of +/-0.02. Locking is by a mechanical-mechanical multiplier and a force selector to ensure constant thrust control.

By using the stepped jaws, you can position the piece at three different heights, thus avoiding use of parallels.

Hydraulic locking is provided for vices TYPE E99-EG99. These vices are known as TYPE OE99-OEG99. Secure locking, without tiring the operator, is obtained by the use of a hydraulic cylinder fitted in the cover and an air-oil pressure multiplier. The carriageis positioned by screw rotation. To lock the piece, just activate the air-oil multiplier valve - the hydraulic stroke is 6 mm.