- About us

- Company details

Fava Giorgio Axel is the Italian leader in food industry automation since 1976.

OUR HISTORY

Our company started in 1976 to produce machines for meat products processing factories, but it already had years of experience in the mechanical field even making machines and overhead rails sold by other companies.

Gradually we extended our offer to other food industry sectors from cheese to sweets, from meat to fish.

These forty years and more of history made us a solid reality with a knowledge that can be acquired only through the experience of many generations.

OUR VISION

Technology in the service of man: smart systems and equipment with a low environmental impact capable of drastically improving the quality of life.

OUR MISSION

The customer and his needs are the center of our company. Our machines have been created, one after the other, on our customers’ requests, to solve different kinds of problems as peak of production, versatility, products standardization, economies of scale.

Needs analysis is always our starting point and every time the challenge is putting together innovation and customization to find the best solution for the buyer, because each company is different in space, logistics, organization. The customer’s special needs give rise to each single project.

Workers’ safety, sanitize, ergonomics and energy-saving are our priorities.

Our technical office designers use 2D and 3D CAD systems and the most advanced calculation models in collaboration with different Universities. All the production phases, from carpentry to assembly, are directly made in our 27.000 square feet factory, and they are supervised with great care by the designers themselves. In this way possible changes and improvements can be done during the executive phase thanks to the cooperation between the technical office and the high skilled personnel that work in the production department.

We believe that the best solution can be obtained only with the contribution of every one, in this way we are able to give to our customers long duration, reliable machines and systems (machines we made in the seventies are still working) and low maintenance costs.

We directly install, start and test the machines. Our customer technical service gives us the opportunity to be constantly informed of our customers’ needs and also to improve our products.

RESEARCH & DEVELOPMENT

We pay a lot of attention to innovations and we constantly improve our products, even thanks to important partnerships.

We developed and registered many patents as, for example, the multi-molds system Legostampo for products to be sliced and the automatic loading system for salamis TFRC.

OUR VALUES

Integrity, accountability, passion and respect for people and for the environment are always our values handed down from generation to generation.

Health, safety and life quality are the linchpins of our company, but also the inspiration of each project we realize.

We only choose partners that protect their employees and customers and that apply themselves in environmental safeguarding as we do.

Year of establishment:

1990

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2016

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of machinery for food, beverage and tobacco processing

Wholesale of agricultural machinery, equipment and supplies

Wholesale of other machinery and equipment

- Videos

- Catalogue

ROBOTIZED PACKAGING LINE FOR MORTADELLA

AUTOMATIC LOADING AND UNLOADING SYSTEM FOR SALAMI, BUTTS, BACON, ETC.

LEGOSTAMPO MULTI MOLDS ROBOTIZED SYSTEM

KEBAB SKEWERING MACHINE

LABELING MACHINE ETIFLEX FOR SALAMI, VEGAN, VEGETARIAN FOOD AND ALSO PET FOOD

No documents uploaded

- Contact Information

- Business Proposals

Company:

FAVA GIORGIO AXEL S.R.L.

Web site:

Address:

VIA CERATI 19/A

City:

PARMA (PR)

Zip Code:

43126

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

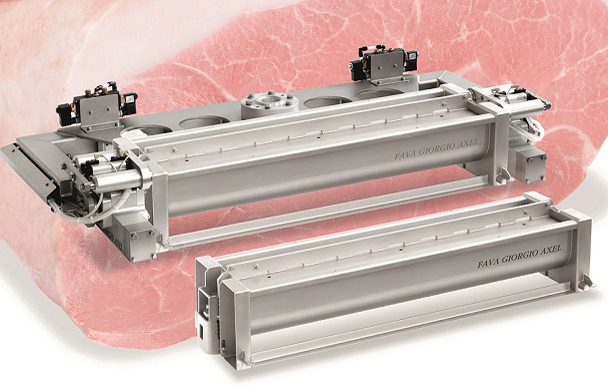

MULTIMOLDS SYSTEM LEGOSTAMPO

OUR LEGOSTAMPO SYSTEM COMES FROM THE NEED TO HAVE A PRODUCT THAT:

as the traditional molds permits to use the same mold during all the production phases and to manage any cooking weight loss, with any cooking technology; as the multi-molds systems optimizes the logistics and the thermal efficiency, enhances the ergonomics and reduces the use of labor for finished product kilo, reduces the request of m² and m³ for each kilo of finished product, improves the slicing yield, even with thinner slices.

OUR SYSTEM PUTS TOGETHER ALL THE ADVANTAGES OF TRADITIONAL MOLDS AND THOSE ONES OF MULTIMOLDS.

LEGOSTAMPO is the flexible system suitable to all production needs, for all the technologies and for all the cooking techniques; the system that satisfies all the requests, starting from R&D to arrive to the most performing and automatized plants.

The molds are easy to move in molding and de-molding lines; the automation is simple, reliable, inexpensive, not bulky, all the same for all the models. The molds are easy to stack firmly, without using straps, presses, compressible frames, ballast and the stacks are simple to move. The best homogeneity of cooking and cooling is guaranteed; the functional layouts are simple and compact.

THE LEGOSTAMPO MULTIMOLDS SYSTEM IS THE BEST TECHNOLOGICAL SOLUTION BECAUSE THE SAME SYSTEM CAN PRODUCE:

Ham in bars for slicing and whole ham

Products cooked in a traditional way with weight loss

Under vacuum, in bag, thermoformed, clipped cooked products

Products cooked with steam and with water, with plants side by side.

Why choose LEGOSTAMPO multi-molds system

It's an ergonomic solution and it doesn't need false molds and molding mechanical device. It's the solution that uses not bulky, inexpensive and reliable moving devices. It's the solution that optimizes the factory logistics, reduces the surface needed for the production and minimizes the energy costs. It's the safest solution with self-stabilizing pile, with no need of using fixing devices (weights, presses, straps…). It's the solution for a simple and gentle demolding, for all the kind of products.

THE INVESTMENT PAYBACK IS FASTER because it reduces the production costs for the automation, the manpower, the facility, and the energy. Because it guarantees the best standardization of all your products. Because it greatly reduces the slicing waste, even with very thin slices. Because it optimizes the yield of your slicing lines. Because it allows a step-by-step investment thanks to a system that grows with your technological and production needs.

WE DEVELOPED MOLDS THINKING TO AUTOMATION, THEY PERMIT US TO OFFER INTEGRATED AND ALL-INCLUSIVE SOLUTIONS:

- Compact and cost-effective molding stations, for all the kinds of technologies, with automations customized on your needs, that can be used even with traditional molds

- Water cooking and cooling units, that can be placed side by side your steam cooking units, without modifying your logistics

- De-molding stations, also for traditional molds, with universal molds washer and with automatic and semi-automatic systems to manage all kinds of molds

- Under-vacuum packaging lines, for bars and whole products, with handling system customized on your needs

- Continuous and intermittent pasteurizing and cooling plants

- Slicing lines feeding systems

- Molds with RFID devices for the complete product's traceability and for the best control of the production's standards.

LOADING AND UNLOADING SYSTEM FOR SALAMI, BUTTS, BACON, ETC.

Handling heavy loads, with hung or laid down products, often is hampered by reduced space and a great quantity of trolleys and frames that normally aren’t realized for automation. Our TFRC loadings handling system solves these problems, because it needs less space than competitors and it has a self-adapting SW to use the existing equipment, as many as possible. Moreover it can be completed with our simple and compact, automatic and semi-automatic products on rods loaders. The TFRC system and the automatic loaders MB are internationally patented.

We projected, patented and made a destructured pilgrim pace system, that is to say a system that permits to load and unload products also on opposite sides without having to rotate the products vertically. The result is a compact system that has the same loading capacity of bigger ones, using the same rods and frames, it doesn’t matter how they are made.

Our plant manages the proper products alignment, it avoids oscillations during handling, it checks the dimensions of each frame and then defines the specific inserting positions, also for quite deformed frames. It can work with very small tolerances and, if necessary, it can also insert bent rods into the horizontal level. No one has overtaken these obstacles.

Often the manual work is the simplest; our MB loaders for products on rods were inspired by the same concepts and for this reason we were able to project and patent a simple, reliable, very compact and in the same time flexible system.

OUR SYSTEMS TFRC AND OUR LOADERS MB OFFER MANY BENEFITS:

- exceptional compactness

- modular realization, easy to enlarge

- very limited floor obstacles for a simpler environmental sanification

- limited oscillations that reduce the contact between the products and the lifting and inserting forks, making sanification easier

- big dimensioning that guarantees a very long life of the components, with negligible maintenance costs

- plant engineering solutions of new generation permit to realize in field connections free from electromagnetic pollution and that can be easily managed inside the cable holder chains, all positioned at the structure top. The structure can be free-standing or it can be fixed at the ceiling and/or at the walls

- the specific choice of the safety devices allowed to reach PL difficult to find in other plant engineering solutions, above all when there is manual handling of frames and trolleys

WHY CHOOSE LOADING SYSTEMS TFRC AND LOADERS MB

- because they are the best solution for small spaces, both in plan and in height

- because they are the solution that fits best the existing equipment, with clear economic profit

- because they are the only front-back systems that guarantee not to lose loading capacity of frames, trucks, trolleys, trees, bars and consequently of the seasoning rooms

- for the exceptional flexibility in the products management, even the biggest ones

- because the great solidity guarantees a long duration system, without expensive maintenance need

- because they are modular and they can grow with your needs

- because the operator interface is simple and easily understood

- because they have remote control and they can dialog with connected machines and means of transports.

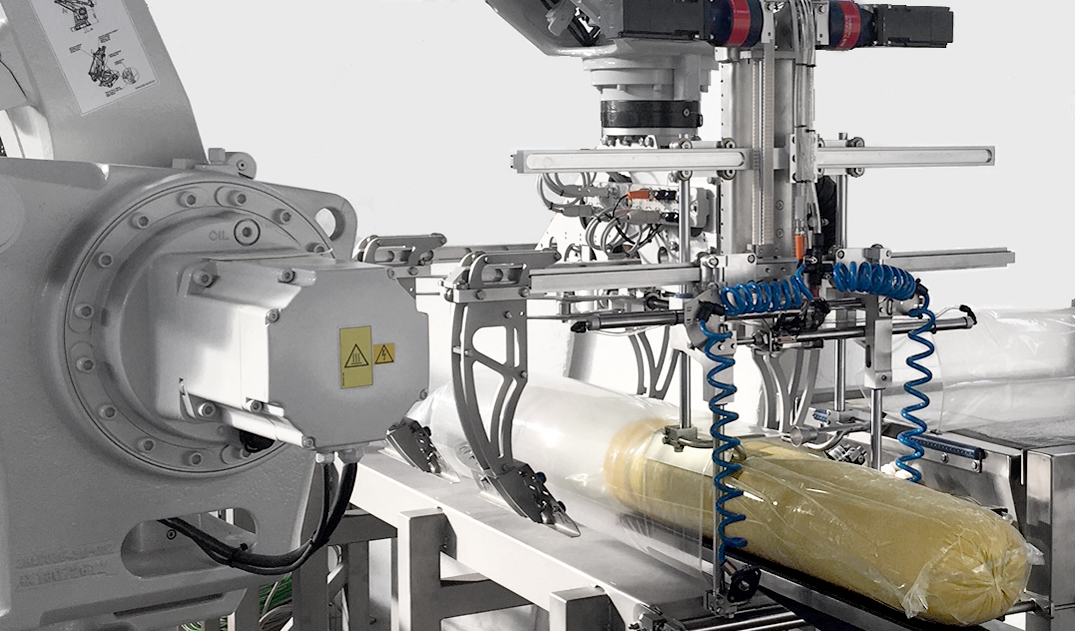

UNDER-VACUUM PACKAGING ROBOTIZED SYSTEM

Robotized system for under-vacuum packaging, for round, square, rectangular products as Mortadella, cold cuts, cheese, vegetables, vegetarian and vegan.

The special patented gripper permits to the robot to pick up the packaging bag, giving it an octagonal profile in a way to reduce plastic consumption, and to put it around the product that is supported by a specific conveyor belt.

The same tool transfers product on an under vacuum welding machine conveyor belt and it flattens the bag mouth to arrange it for welding.

The gripper is really flexible and it can treat in the same line products having diameter from 100 mm to 290 mm, till one meter long.

If the requested productivity is high two robots can load the same under-vacuum machine with double welding bars, reaching a productivity of 720 pieces per hour.

The same system can be used for flow packed products. Each plant is custom-made.

KEBABS SKEWERING MACHINE for making skewers with meat, fish, cheese, vegetables and fruits

The project of our kebab skewering machines arises from the need to have machines easy to clean, that can be used with different products, that can change with the different production needs, not bulky, not noisy and inexpensive.

WE REACHED THESE GOALS MAKING KEBAB SKEWERING MACHINES:

- modular, in a way to increase the number of operators that load the products molds to make the kebabs, so that the machines can grow together with the customers production needs

- with molds easy to pull out, for a simple sanitization with suitable washers, consequently easy to substitute to produce kebabs with different number of pieces, with different shapes and different lengths

- that can use sticks having different diameter and length, with or without protruding tip

- that can use paddle sticks, of different lengths, and also round sticks

- with pre-piercing unit for more compact and resistant products

OUR KEBAB SKEWERING MACHINES HAVE THE FOLLOWING BENEFITS:

- the same sticks insertion head for all the different models

- simple and functioning realization, for the best reliability, for low noise and moderate price

- operator panel simple and easily understood, to adjust the production frequency on the machine dimensions and on the kebab complexity

- simple sanitization not only for the detachable molds, but also for all the machine with special attention to the molds conveyor belt

- easy access to all the parts of the machine

It’s very simple to customize the machine on products dimensions, for example inserting 2, 3, 4 sticks in one time with clear production increase.

We have, in our production range, a basic, pneumatic model named SPDP and modular, electronic models called SPDE and SPDEF.

The SPDE model, for round sticks, in the different modular configurations, can produce from 1,800 to 7,200 kebabs/hour, with a number of operators at loading that can vary depending on the complexity of the kebabs and on the requested productivity.

The SPDEF model, for round sticks and paddle sticks, in the different modular configurations, can produce from 1,200 to 3,600 kebabs/hour, with a number of operators at loading that can vary depending on the complexity of the kebabs and on the requested productivity.

We also produce a small Kebab (arrosticini) manual skewering machine, an inexpensive solution for small production.

THE MODELS SPDE AND SPDEF CAN HAVE THE FOLLOWING OPTIONS:

- finished kebabs receiving belt

- finished kebabs receiving belt - lower - and their transfer to the working table

- automatic kebabs insertion device in preformed trays to be thermo-sealed

- molds conveyor belt inner side washing device.

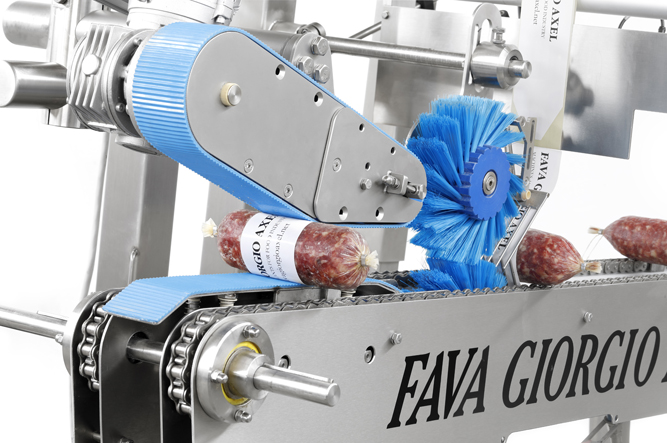

LABELING MACHINE ETIFLEX for labeling salami, vegan, vegetarian food as well as pet food

Automatic labeling machine not only for salami, but also for vegan and vegetarian food as well as pet food.

The automatic labeling machine ETIFLEX is suitable for cylindrical products, but even for flat and U-shaped salami.

The machine can label products having diameter between 30 to 120 mm and length between 120 and 600 mm.

The machine can use, with simple adjustments, labels having a width included between 30 to 220 mm and the production can reach 2600 pieces/hour, depending on the product and label characteristics.