- About us

- Company details

Since 1930, here at SCAM we took the utmost from the very advanced technology related to Thermotechnics.

We become renowned, we gained our prestige and quality we are known for today by providing to public and private industries the best components, supplies and assistance. With our technological exptertise, we helped sectors such as energy, industrial engineering, petrochemical, and more, but also military and merchant navies, with clients over 70 different countries worldwide.

We are proud to design and manufacture in Italy our Vacuum Groups and Vacuum Pumps, Steam Ejectors, Steam Condensers, Heat Exchangers, Desalting Plants and Reverse Osmosis System, Air/Water/Oil Coolers, Salinometers, Deaerators.

Our main strenght is the lifespan of our products. After 40 years of continuous activity, our clients still use our vacuums, and we are always ready to supply them with new spare parts to extend further the pumps working life.

The mission of the SCAM Team is to pursue quality excellence in production, to guarantee a long life to our plants and equipments and to provide the best customer service. This is the vision that our CEO, Giorgia Garola has for the company, an excellent example of female entrepreneurship that is keeping SCAM reputation high.

Year of establishment:

1985

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2001

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of basic metals

Machining of metals

Manufacture of other pumps and compressors

Manufacture of other general-purpose machinery

Manufacture of non-domestic air conditioning equipment

Installation of other industrial machinery and equipment

- Contact Information

- Business Proposals

Company:

S.C.A.M. - S.R.L. - SOCIETA' DI CONDENSAZIONE ED APPLICAZIONI ME CCANICHE

Web site:

Address:

CORSO ORBASSANO 368/24

City:

Scam Srl TORINO (TO)

Zip Code:

10137

Social media:

Tag:

No business proposals uploaded

- Map

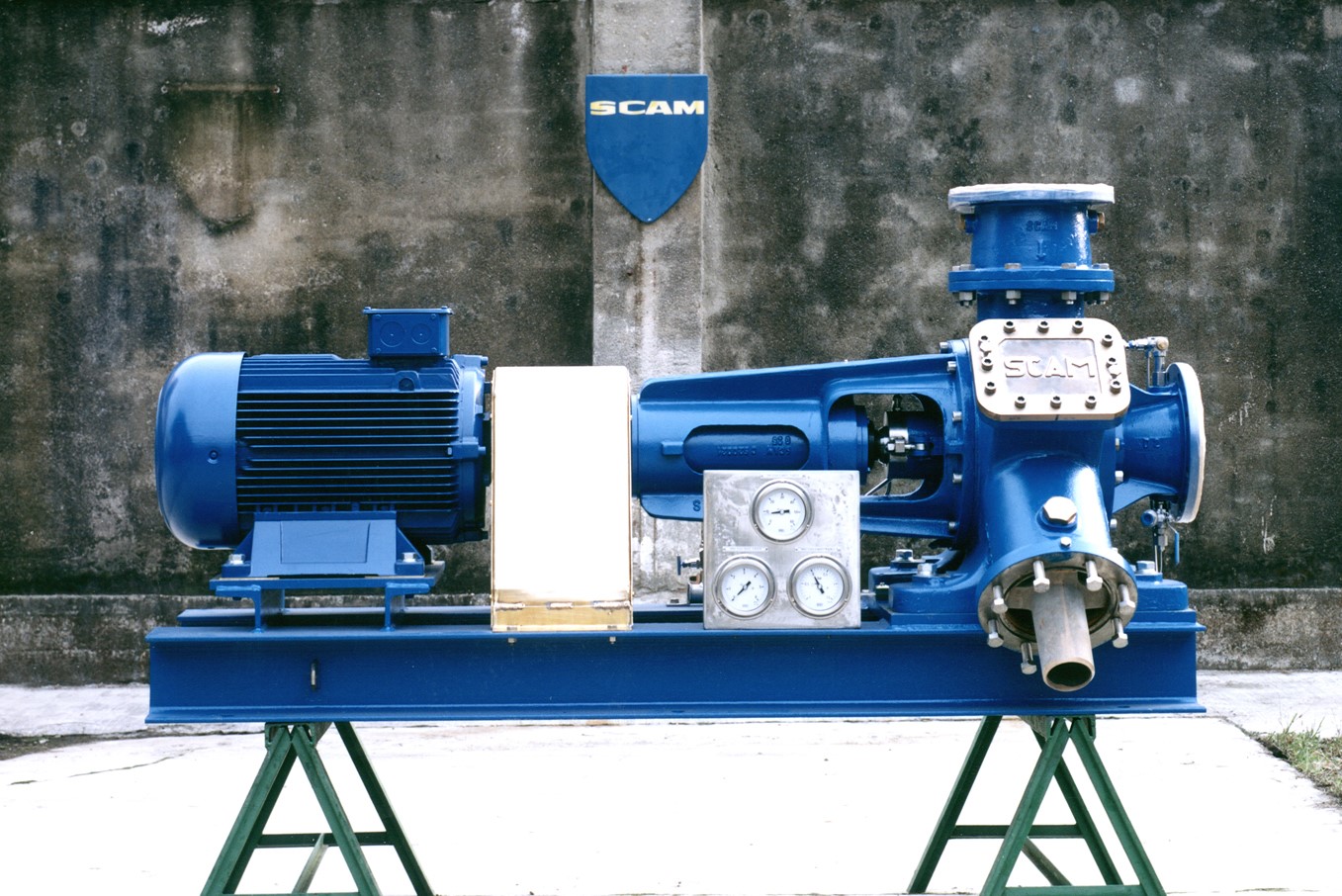

1 - SCAM VACUUM GROUP

SCAM has always met the various customers’ requirements who demanded not only each component but a whole-package plant, which includes all accessories in order to reduce the installation time, order numbers, tests, inspections, ect.

In order to satisfy such requirements, SCAM has included in its production lines, the Vacuum Group, especially for vacuum sector.

These are divided into:

- Vacuum Group with SCAM vacuum pumps

- Vacuum Group with steam jet ejectors

- Vacuum Group with hybrid system SCAM pumps plus ejectors

Each one has as a middle element the pump or the ejector but to these can be added:

- Exchangers

- Regulation Valves

- Storage Tanks

- Pipeline

- Instrumentation

- Electric Wires

- Insulations

- Single bedplate

In this way the installation is enormously facilitated by reducing the connections to a few pipes and electric cables.

2 - SCAM EJECTORS

SCAM has been designing and manufacturing more than 17,000 ejectors of different typers for various applications: single or multi-stage types with intermediate or final surface, or even mixture condensers.

The most frequent applications are in energy and production industries. Furthermore, countless chemical and petrochemicalplants adopt ejectors for keeping the vacuum necessary for processing fractional distillation, crystallization, drying, deaeration, filtration and impregnation. Particularly, all the plants for deodorization and fatty acid treatment built are fitted with steam jet thermocompressor ejectors which allow very low final residual pressures.

The possible appilcation are multiple and very diversified: the "flash effect" cooling (instant vacuum evaporation), the maintenance of vacuum in test rooms for the simulation of flights, the degassing of moulded steel during casting operations in steel mills, are just some of the most recent ones.

3 – SCAM VACUUM PUMPS

We can easily affirm that SCAM pumps are part of all the biggest Thermo-electric and Conventional Power Plants, Steel Mills and Desalination Plants throughout Italy. The continuous technological development and recent modifications brought on SCAM pumps and on vacuum auxiliaries, which are integrated thereto, make the pumps suitable for all kinds of applications. Also, SCAM air pumps also solve vacuum problems, starting from high pressure.

Ranging from 2 KW to 75 KW, SCAM air pump keeps incondensable substances at a very low level and with the best efficiency in terms of reliability and consumption. Our pumps intake, at a high vacuum degree, a mixture saturated with air and saturating steam at a much higher temperature than the plant cold water.

After 40 years of continuous activity, our clients still use our vacuums, and we are always ready to supply them with new spare parts to extend further the pumps working life.

4 – SCAM STEAM CONDENSER

SCAM can supply various steam condensers construction types thanks to the experience and design in this sector which dates back to 1930.

Our technical research here at SCAM has never stopped, it continued on many lines.

We improved fluidics by studying tubes distribution and open spaces in order to:

- reduce the load losses

- improve the steam distribution inside the tube bundle;

- improve the thermal exchange capacity;

- reduce the total dimensions

We carried out mechanicals improvements sych as:

- reduction of load losses

- improved steam distribution inside the tube bundle;

- better thermal exchange capacity;

- reduction of the total dimensions

We used new materials for various components (tubes, plates, shell ect.) to guarantee the maximum duration period without need of special maintenances and we adoptednew assembly technics to reduce the thermal stresses on various components (waviness according to Brown Boveri method, flexible head plates ect.)

5 – REVERSE OSMOSIS SYSTEM

For many years, SCAM has been active in the design and manufacture of on-shore and marine plants for the production of fresh water from sea water, the SCAM Reverse Osmosis Plants (or RO Plants/Reverse Osmosis System).

Experience, new studies, and the technical co-operation with Engineering Companies and Test Institutes, allowed us to develop a line of package type "Reverse Osmosis Sea Water Desalting Plants", with a capacity ranging from 1 to 2,000 T/day. For higher outputs, SCAM-RO plants are designed every time according to our Customers' requirements.

Pure and ultra-pure water produced by means of the Reverse Osmosis system is specifically recommended for the following uses:

- Water for irrigation and cultivations of vegetables and fruits in dry places and in ostile seasons

- Water for industrial uses (pharmaceutical, cosmetic, microcircuits, soft drinks/beer, ice) and optimal for high pressure boilers

- Plants both for military and merchant navies

Package type SCAM-RO units are very easy to install: they are pre-assembled on a sturdy frame and can also include optional auxiliary accessories. All our SCAM-RO units are tested at our Workshop before the delivery.

We put our experience and hard work into optimizing those systems on all sides. The energy recovery of our SCAM-RO systems provides a substantial reduction in plant running costs and we provide a wide range of membranes for any specific requirements our customers have.