- About us

- Company details

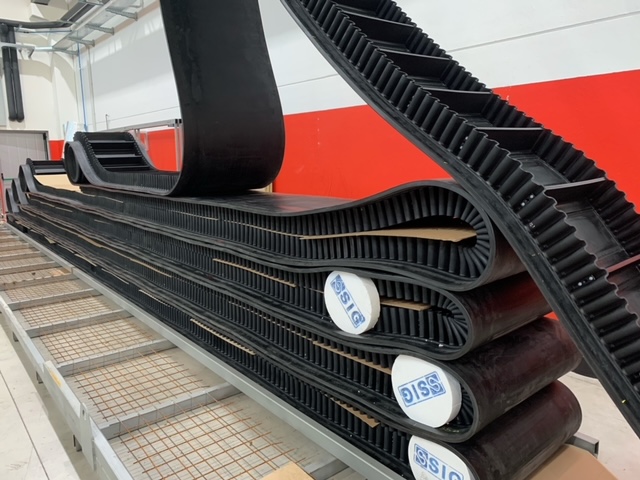

SIG is the Italian leading as one of the European most important producers of elevator as well as rubber conveyor belts.

With an experience of more than 50 years manufacturing SIG can easily supply high quality made in Italy synthetic and steel rubber belts worldwide.

Since the end of 60’s, our production plant is located in Gorla Minore, Northern Italy, close to Malpensa Airport and Milan city center. In this 12000 sqm area, you could also find SIG headquarter as all the company key position, from purchasing to commercial and technical teams work all together really next to the factory.

This specific organization allows all the company workers having a flexible approach to business, satisfying all customer’s needs as well as international market requests. The close cooperation between our technicians and our sales Department members enable SIG to find solutions to any type of problem.

Concerning the production process, our factory has a capacity of 400 km every year, manufacturing any type of rubber belt, up to 2200 mm of width and weight for every roll, covering any industrial field, from cement to iron factories, passing through coal power plants, ports and terminals, mines and quarries as well as chemical factories.

Specific rubber covers are available to efficiently and safely handle the most critic bulk materials like hot clinker, flammable coal, oily waste and fertilizers, highly abrasive bauxite and iron ore. Specifically talking, all the cathegories are:

❖ Abrasion resistant

❖ Heat resistant up to 200°C (390°F), with peaks of 300°C (490°F)

❖ Chemical, fat and oil resistant

❖ Self-extinguishing and antistatic as per to ISO 284 & ISO 340 or EN 12882-1

RUBBER BELTS:

➢ TEXTER: it has EP (nylon and polyester) carcass,

it is the most common category of rubber belts;

➢ SIDERFLEX: known due to its steel cord carcass used for heavy and long conveyors granting high resistance to cut as impacts, but still with high transversal flexibility;

➢ PIPEX & PIFLEX: manufactured in both steel and textile carcass, for tubular shape;

➢ ARABELT: as suggested by its name, it has got a special aramid carcass that lets it be the strongest product of our range, defeating any type of threat;

➢ RIPSAVE: multiple plies rubber conveyor belt with a transversal steel reinforcement in the top cover;

➢ TEXBIND: mono-ply polyester-nylon straight warp construction with double special reinforced weft;

➢ FLEXOBORD: sidewall belt for inclined applications.

ELEVATOR BELTS:

➢ ELEMET: it is manufactured with a steel carcass for heavy and hot applications;

➢ ELETEX: it is manufactured with a textile carcass.

All the elevator belts can be punched according to customers instructions. All rubber covers are antistatic as per ISO 284.

Meanwhile, SIG is not only rubber conveyor & elevator belts, but also manufactures special technical articles, including special tracks for snow mobile machines.

Year of establishment:

1980

Number of employees:

FROM 50 TO 99 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2001

Export turnover:

0

Activities:

Manufacture of other rubber products

Manufacture of plastic plates, sheets, tubes and profiles

Manufacture of tubes, pipes, hollow profiles and related fittings, of steel

Manufacture of lifting and handling equipment

Manufacture of machinery for mining, quarrying and construction

- Videos

- Catalogue

Our history from our day one since nowadays. SIG is the one and only Italian leading manufacturer of both rubber conveyor as elevator belts with EP or steel carcass since 1945. With our production centre based in Gorla Minore, near Milan, we have been supplying 66 countries all over the five continents.

Our company profile explains to you a bit about our history from the beginnings in 1945, the moment from which thanks to our four most important pilars, commitment, dedication, experience and knowledge, we have been able to meet all the different international market requests.

ARABELT® is a conveyor belt characterized by only one ply with a special construction named “straight warp”. This is a special weaving where the longitudinal filaments (warp) are not braided with the transversal ones (weft); furthermore, the connection between warp and weft is assured by a special nylon binder.

SELF-SUPPORTING CONVEYOR BELTS FOR COVERING AND SEALING APPLICATIONS. The ultimate solution to stop material spillage. Sealtex is supported over lateral holders and thanks to its high transversal rigidity stays over the underlying conveyor; in this way, material spillage is avoided. Then, when necessary, it can be lifted up to allow the passage of discharge tripper or loading hoppers.

EpP: polyester-nylon straight warp construction with double special reinforced weft. Texbind belts have been originally designed as an universal mining conveyor belting to provide maximum flexibility together with high resistance. Now, Texbind are available as profitable alternative of multiply conveyor belts in case of heavy applications where impacts with big-sized materials are present.

- Contact Information

- Business Proposals

Company:

S.I.G. SOCIETA ITALIANA GOMMA S.P.A.

Web site:

Address:

VIA SELLA Q. 0004

City:

GORLA MINORE MILANO (MI)

Zip Code:

20121

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

TEXTER: rubber conveyor belt with EP carcass suitable for flat material conveying.

TEXTER is SIG most known rubber conveyor belt with EP carcass, composed of nylon as polyester fibers.

Available in many different rubber compounds from abrasion to heat and oil resistant, but also self-exstinguishing, it conveys several crucial advantages:

- It is an EP carcass #rubberconveyorbelts with excellent flexibility but also having a reduced permanent elongation;

- It is high resistant against cut and tears;

- Insensitive to humidity;

- Excellent adhesion between nylon and polyester carcass and top as bottom covers

- It is suitable for a wide range of industrial applications, such as cement or steel plants, grain industry and also mines & quarries.

Web site

http://www.sig.it/

SIDERFLEX: rubber conveyor belt with steel carcass perfect for any long distance bulk handling conveying

The carcass of SIDERFLEX belts consists in a brass coated steel fabric with low elongation characteristics which gives to the belt a high tensile strength.

The greatest advantage of the low elongation for conveyor belts with a center distance not extremely long is the possibility to replace textile belts without significant modifications of the conveyor system.

This type of carcass gives to SIDERFLEX belts special qualitative characteristics of:

• Excellent cut and tear resistance

• Low elongation

• High tensile strength

• Good impact resistance

• Excellent longitudinal flexibility

• Very good troughability

Web site

http://www.sig.it/

PIPE CONVEYOR: PIPEX is the tubular rubber conveyor belt with EP carcass whereas PIFLEX is the tubular rubber conveyor belt with steel carcass

Pipex and Piflex are conveyor belts designed for tubular conveyor systems equipped with a textile or a steel cord carcass, respectively.

The special production method for this important product is the result of exhaustive tests and proper theoretical evaluations which allowed to obtain Pipex and Piflex

belts whose main characteristic is a significant transversal flexibility.

The tubular conveyor system is designed to allow the belt to wrap around the conveyed material while it remains flat at loading, discharging areas and takeup zone.

Consequently, over the full conveying length, Pipex and Piflex belts are shaped into a tubular section by idler frames properly arranged in hexagonal form.

Main advantages of this technology are:

• Horizontal and vertical curves with reduced bending radius

• Little space requirement by compact plant design

• Reduced spillage of materials loaded from the belt

• Dust free transportation

• Low maintenance

Web site

http://www.sig.it/

ELEMET & ELETEX: rubber elevato belts with steel and textile carcass respectively

Due to the high quality of steel cord, it is possible to design ELEMET with very low safety factors.

➢ ELETEX – TEXTILE ELEVATOR BELTS

Belts designed to be used in bucket elevator plant only. The special construction of the reinforced polyester-nylon fabrics assures the use of such belts also for severe loading requirements.

The result are the following:

• Polyester warp assures high resistance to heavy working conditions.

• Nylon weft guarantees transverse tearing strength and strong bolt holding.

All ELETEX are supplied with cut edges because synthetic fabrics used for their production do not need protection against humidity as they can’t absorb any liquid. The 2 mm thickness both for top and bottom cover is designed to protect the carcass and at the same time assures the best bucket

support without bolt loosening.

Web site

http://www.sig.it/

FLEXOBORD: sidewall belt for inclined applications.

Flexobord is a conveyor belt used for conveying material, particularly

useful when the inclination angle of the elevation system is very steep.

Its strength is given by the increasing of handling capacity, the absence of

material spillage, the low power and maintenance required.

The main application fields of this belt are:

• Steel plants

• Mines

• Cement Plant

• Foundries

• Batching plants

• Power plants

• Tunneling

The correct choice of each component in relation to the final use is one of the

most important contribution to the overall plant performances.

The complete range of SIG belts is produced according to the international standards; therefore the cross reinforcement of the carcass ensures the necessary transversal stiffness and prevents from hitting the full width return idlers.

According to the heaviness of the application, the following base belt typologies are available:

XR Composed by only textile fabrics with high transversal stiffness, feature provided by 2 additional special synthetic layers set in the cover rubber, assure the correct cross stabilizing properties.

They are provided with cut edges for light and medium applications. This base construction can be sold as independent product with the brand name TEXRIGID®

SR Composed by a mix of multi-ply synthetic carcass and suitable steel reinforcement to ensure high transversal stiffness for heavy Flexobord applications.

They are provided only with moulded edges. This cross stabilized base belt can be sold as independent product with the brand name CROSSRIGID®.

ST Designed for the heaviest applications where high elevation and/or conveying capacity are involved, it is composed by longitudinal steel cords with a special transversal steel reinforcement to assure the required stiffness.

This cross stabilized base belt can be sold as independent product with the brand name CROSSRIGID HR®. This belt type has a steel cords internal structure.

Web site

http://www.sig.it/