- About us

- Company details

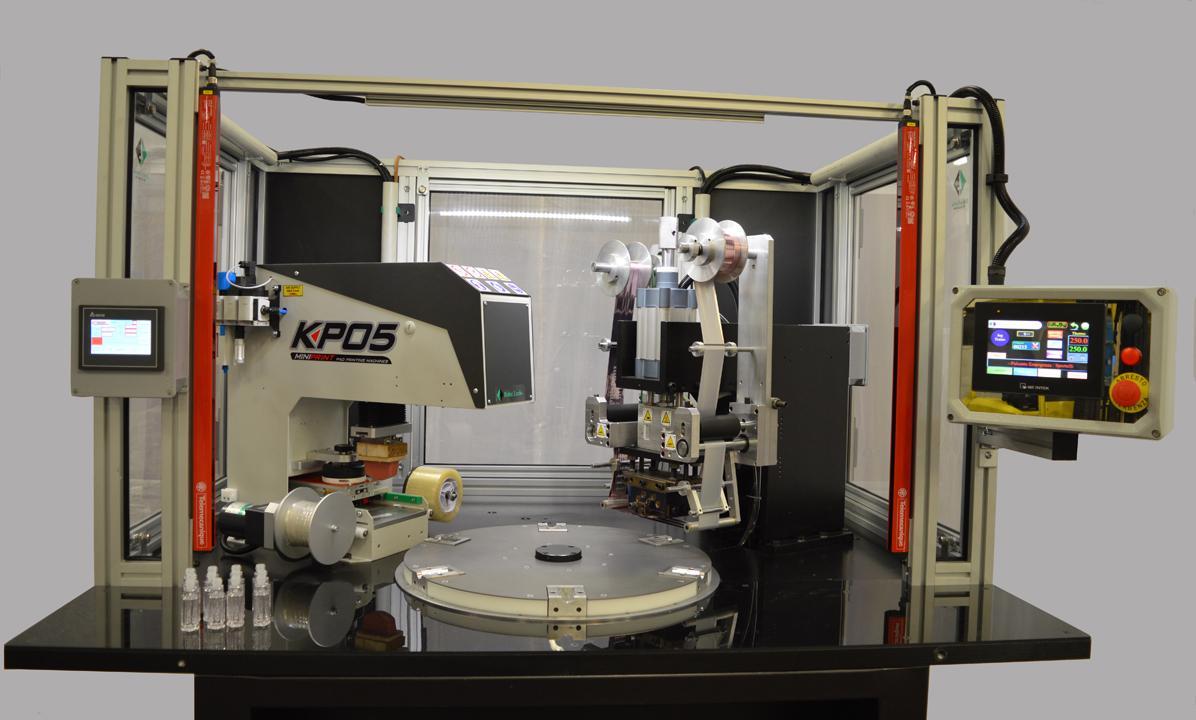

We are designers and manufacturers of HOT FOIL MACHINES

Wide range of hot stamping machinery intended for various application sectors, with particular regard to: wine & spirits, cosmetics, paper converting, ecology, clothing, household appliances, automotive. All our machines can be customized to the customer's needs, and can be equipped with vision systems and automations for the management and movement of the pieces. We also create prototypes for specific needs and equipment to be installed on the customer's production lines.

Machines available with techniques combined with hot foil: embossing, pad printing, transfer, digital, etc

Examples of products that can be hot decorated: metal or plastic capsules and bottle caps, shopping bags, roll paper, coat hangers, cardboard boxes, special papers, bottles, jars, lids, mascara, lipsticks, containers of various kinds, wooden or plastic caskets, cages and bins of various sizes, parts of household appliances, leather labels for clothing and much more.

Our strengths: over 60 years of know-how, reliability, great flexibility, problem-solving aptitude, pre- and post-sale customer support, remote connection assistance, onsite assistance.

(*) technique for decorating objects: the color contained in the tape called "foil" is transferred to the object by means of the heat and pressure exerted by the machine. The settings are managed by PLC

Characteristics: high color rendering, exceptional brilliance and greater resistance over time compared to ink techniques. “Green” solution: it does not require solvents and does not produce dangerous waste.

Used on: plastic, paper, cardboard, special papers, leather and similar, wood, painted metals, glass, etc.

Year of establishment:

1963

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2023

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of leather machinery

Manufacture of printing and bookbinding machines

Repair and maintenance of machinery

- Contact Information

- Business Proposals

Company:

DOLCE LUCIO SRL

Web site:

Address:

Via Buonarroti 8

City:

PERO (MI)

Zip Code:

20016

Tag:

No business proposals uploaded

- Map

HOT FOIL MACHINE ON CAPSULES

MACHINES FOR HOT FOIL PRINTING ON aluminum or plastic CAPSULES with a closing function for bottles of wine, spirits, oil, cosmetic or pharmaceutical bottles, etc. Various models available for printing on the head, on the side of the capsule or both, also with the possibility of creating relief (on aluminum capsules).

All machines can be customized and equipped with vision systems and automations for the management and movement of pieces

HOT FOIL MACHINES FOR COSMETIC

MACHINES FOR HOT FOIL PRINTING ON COSMETIC PACKAGING of various types: caps, lids, jars, bottles, mascara, lipsticks, boxes, caskets, etc. of various materials: plastic, metal, cardboard, glass, etc.

Printing flat, round, elliptical, etc. Possibility of printing in combination with other techniques: embossing, pad printing, transfer, digital, etc.

All machines can be customized and equipped with vision systems and automations for the management and movement of pieces

HOT FOIL MACHINES FOR SHOPPER OR SPECIAL CARDS

HOT FOIL PRINTING MACHINES ON ROLL PAPER specifically dedicated to the decoration of roll material intended for making SHOPPER, packaging products, etc.

Hot foil printing and embossing on low to high weight paper, laminated paper, etc.

Reel-to-reel and reel-to-sheet machines

Machines for decorating already packaged bags are also available.

All machines can be customized and equipped with vision systems and automations for the management and movement of pieces

HOT FOIL MACHINES FOR BINS / CRATES / BASKETS / BOXES

HOT FOIL PRINTING MACHINES equipped with anvil for printing on waste bins, boxes and baskets for various uses (e.g. fruit and vegetables), boxes and bags, caskets, etc.

Application sectors: ecology, pharmaceuticals, cosmetics, paper industry, agriculture, oenology, jewellery, gifts, etc.

All machines can be customized and equipped with vision systems and automations for the management and movement of pieces

HOT FOIL MACHINES FOR AUTOMOTIVE / HOUSEHOLD APPLIANCES

MACHINES FOR HOT FOIL PRINTING ON HOUSHOLD APPLIANCE OR AUTOMOTIVE PARTS of various shapes, sizes and materials such as refrigerator drawers, knobs, dashboards, etc.

Possibility of printing in combination with other techniques: pad printing, transfer, digital, etc.

All machines can be customized and equipped with vision systems and automations for the management and movement of pieces