- About us

- Company details

Simply passion for our job, desire to share our knowledge, pride of meeting our customers’ expectations: for this reason, when we talk about packaging machines, we give priority to the human being. We exactly know that the value of each machine is rated by the ability of doing properly what it has been built for. Every customer becomes a partner who imagines the possibilities and who looks for the solution to which we give shape and substance.

Any idea is evaluated to be the most rational as possible; it is designed, tested and applied. Every project becomes an opportunity to further improve what we do. We offer customized solutions aimed to satisfy the needs of that person that will employ it; machines with reduced maintenance time and operating costs, machines easy and intuitive to be programmed. This is our thought, that is realized with the help of all means that modern technology offers to reduce energy consumption, but without losing sight of the needs of those who will daily use the machines we build.

Simplicity is the ultimate sophistication.

Year of establishment:

2011

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2024

Export turnover:

From 2.5 to 5 million Euro

Activities:

Manufacture of packing and wrapping machinery

Manufacture of machinery for food, beverage and tobacco processing

Packaging activities of beverages and food

Packaging activities of other goods

- Videos

- Catalogue

No videos uploaded

- Contact Information

- Business Proposals

Company:

LAFER PACKAGING SRL

Web site:

Address:

VIA LAGO DI GARDA 104

City:

SCHIO (VI)

Zip Code:

36015

Social media:

Tag:

No business proposals uploaded

- Map

Disko: wrapper for hard candies

High-speed horizontal packaging machine for candies and lollipop individually wrapped in pillow bag.

DISKO basic version provides single packing of hard candies and can be equipped with proper optional devices to obtain bags in chain with pre-cutting, multipack, packing of chicklets, packing of lollipops, inclusion of gift.

The electronics developed directly by our technicians and the high-speed sealing can grant better performances, making us highly competitive in the market.

Web site

https://www.laferpack.com/disko-192

Planet: full servo flow wrapper with three Brushless motors especially designed for manual loading.

Medium speed full servo horizontal wrapping machine suitable for manual loading or to be linked in low/medium speed automatic feeders.

PLANET project is developed based on friendly use concept: balcony frame execution and intuitive HMI graphic software, are only few highlights which added to a wide range of optional and the high flexibility bring Planet to revolution the concept of entry level machine.

Motion: horizontal packaging machine for products with gas flushing packaging (MAP)

Motion is the ideal packaging machine for products like meat with MAP, bread with MAP, cheese with MAP, sandwiches with MAP.

The box motion sealing system ensures welds hermetically sealed for MAP packaging.

Motion is suggested to obtain high aesthetically good-looking design with side gussets and in case of packing with thick materials.

Web site

https://www.laferpack.com/motion-189

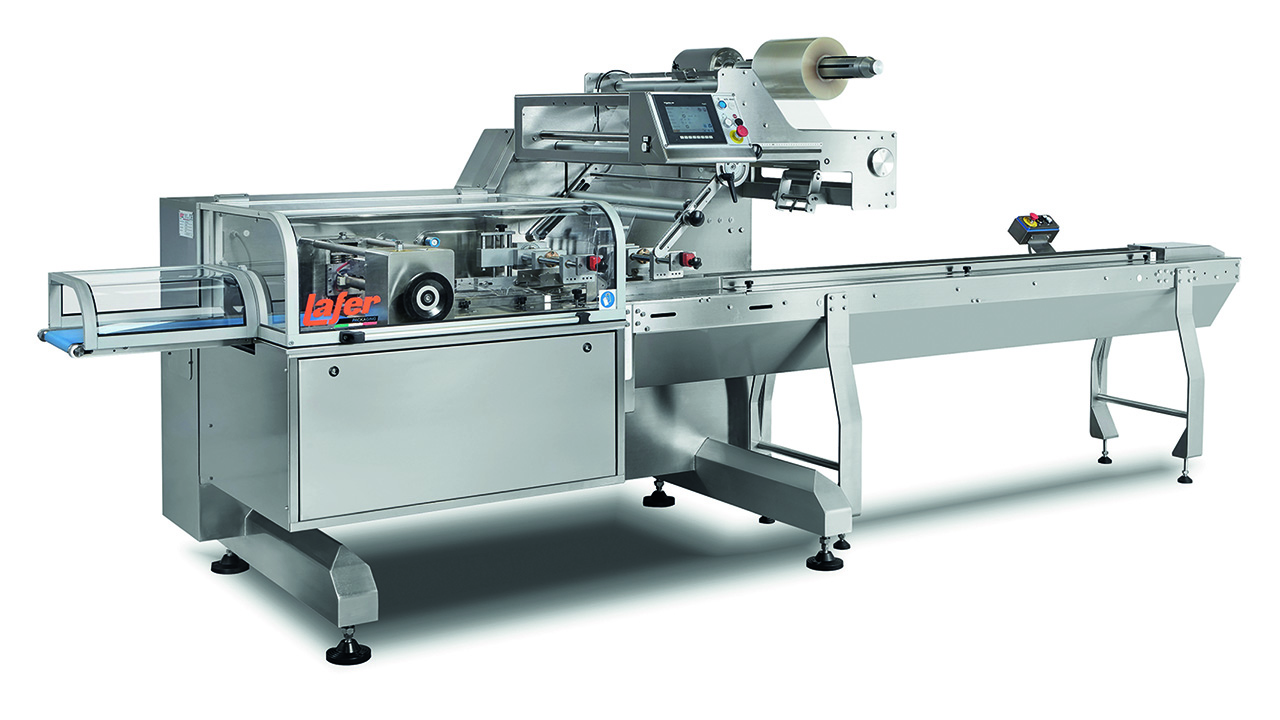

Cosmic: horizontal packaging machine, suitable for manual loading or to be integrated with low/medium speed automatic lines.

COSMIC project is coming from the Lafer Packaging high speed wrapping machines technology.

The same musts of the gamma’s top machine are applied on COSMIC: balcony frame execution, friendly use HMI graphic software, complete access to the operation area of the machine protected by wide safety covers are only few highlights which added to a wide range of optional.

COSMIC is a great solution for bakery products:

- baguette, bread, buns, hot dog, sliced bread

- breadsticks

- small panettone.

Web site

https://www.laferpack.com/cosmic-187

Fast: fully electronic packaging machine developed for high performance platform.

The FAST horizontal packaging machine is designed to work continuously while combined with automatic feeding systems.

Equipped with double pneumatic reel holder shaft, automatic reel splicer, longitudinal seal assembly with preheating device, cross sealing head with double jaw, friendly use HMI graphic software with provision for printer and up-stream/down-stream control interface.