- About us

- Company details

Our company designs and manufactures heat treatment equipment for components made in steel or aluminum alloys (furnaces, quench tanks, charging machines and manipulators). Turnkey systems. Automatic or semi-automatic systems.

Our customers may be: steel producers, foundries, forging companies, heat treaters.

Year of establishment:

1995

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2023

Export turnover:

From 750.000 to 2.5 million Euro

Activities:

Heat treatment of metals

Manufacture of machinery and equipment nec

Manufacture of ovens and furnaces

Manufacture of other lifting and handling equipment

- Contact Information

- Business Proposals

Company:

HI-TECH ENGINEERING S.R.L.

Web site:

Address:

VIA OLIVETTI 13/9

City:

TORINO (TO)

Zip Code:

10148

Social media:

Tag:

No business proposals uploaded

- Map

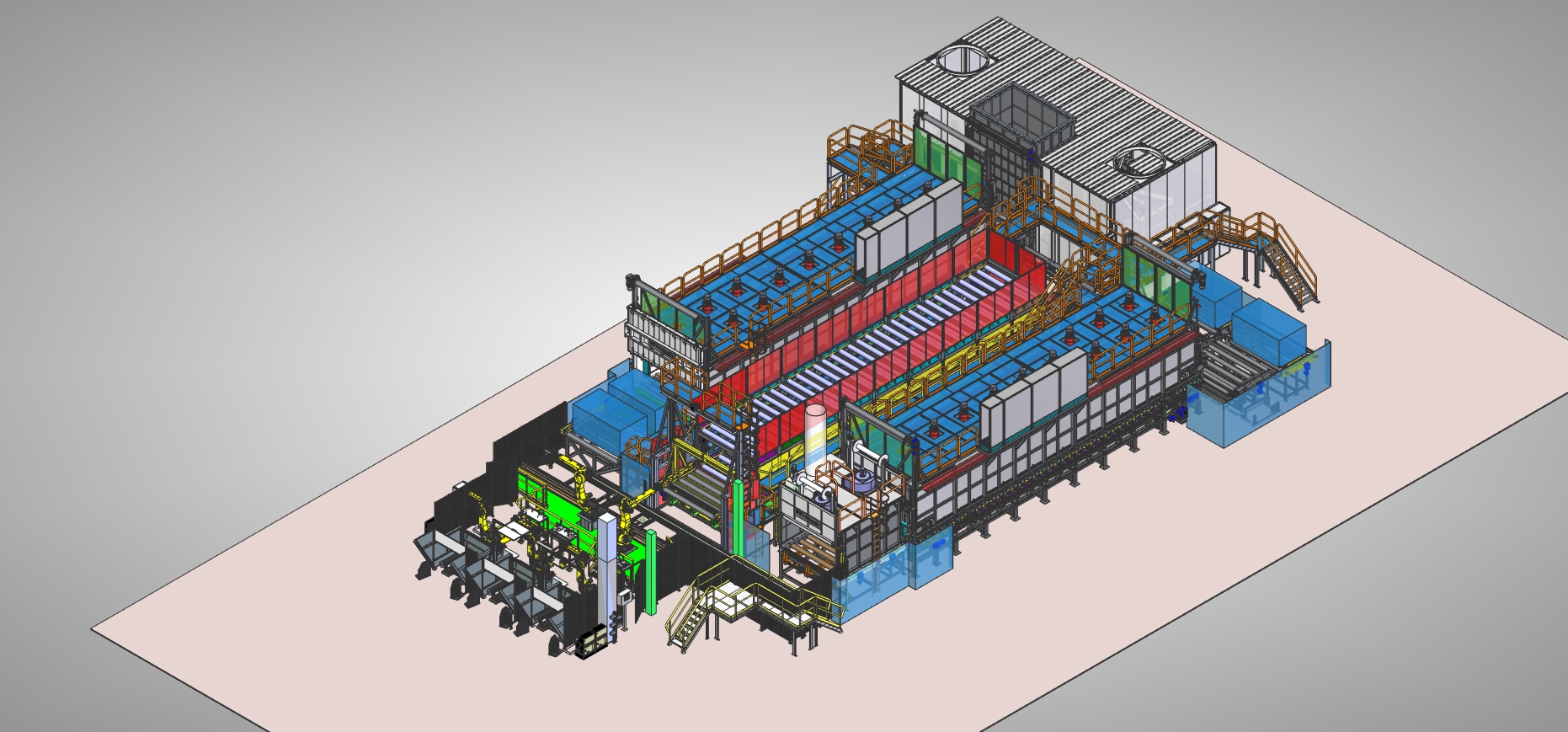

Aluminum - Heat Treatment Continuous Roller Line

Roller-type continuous line for parts placed in racks (e-mobility parts). Closed loop line for solution - air quench - aging with automatic loading and unloading of parts from the racks. Completely automatic. Electrically heated.

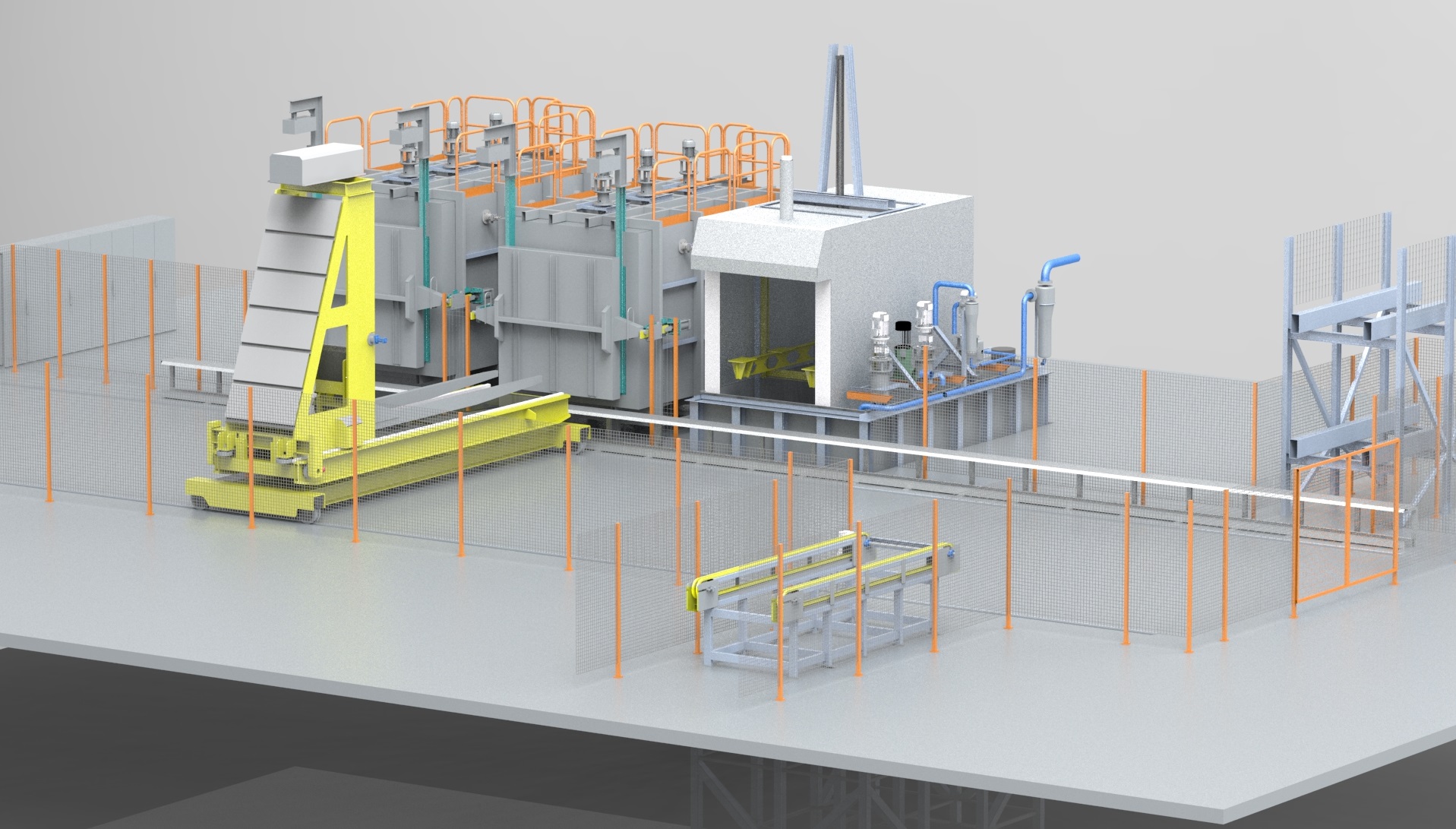

Aluminum and Steel - Modular Batch Type Line

Box type furnaces - automatic charging machine - quenching systems (air, water, polymer, oil). Manual - Semi-automatic - Completely automatic. Electrically or gas heated. Modular, expandable and versatile.

STEEL - Continuous Heat Treatment Line for bars

Roller Type Heat Treatment Line for Bars (square or round) with austenitizing furnaces, quench systems, tempering furnaces, colling systems. U-shaped, L-shaped or I-shaped. Electrical or gas heated. Completely automatic (robot loading) or manual (ergonomic).

Charging Machines

Charging Machines attending the box type furnaces and modular heat treatment lines. Transfer time: 35-60 seconds. Capacity: 2 tons-40 tons. Self-rotating solution or one-side solution.