- About us

- Company details

Thanks to its experience of almost thirty years in manufacturing cable taping lines, single-twist stranding machines, cable sintering ovens and camera vision system for in-line quality inspection, WTM has become the reference for producers of special high-performance cables all over the world.

The cables produced wth WTM machines are designed for many different applications: aeronautical and aerospace sector, instrumentation, high speed data transmission, telecommunications, automation on industry, commercial and military strategic sectors, and more.

Thanks to the deep knowledge of cable construction, materials and their application methods and to the experience coming from hundreds of machines produced, WTM studies the specific production needs and designs the suitable solutions to optimize the production processes of its Customers.

Thanks to a highly qualified team and modern diagnostic tools, WTM provides timely analysis of the functionalities of its equipment: a key service to increase the operational efficiency and to reduce downtime costs.

WTM staff is ready to analyze in depth the technical characteristics of the cable to be produced and to support the Customer in identifying the machine that optimizes its production process.

Year of establishment:

1993

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2023

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of machinery and equipment nec

Manufacture of other special-purpose machinery

Manufacture of all other various special-purpose machinery nec

Architectural and engineering activities; technical testing and analysis

Architectural and engineering activities and related technical consultancy

- Videos

- Catalogue

Take a look inside WTM world

Look at the stability of this PTFE tape in the taping point. Despite the speed of 1750 RPM, there is no vibration due to the air pressure, generated by the rotation of the taping head: this thanks to the WTM dynamic dancer technology.

WTM different solutions for manufacturing high-quality special cables thorugh stranding process: single-twist cable stranding machines with double pintles or shaft design, rigid and planetary cable stranding lines and concentric backtwist pay-off units.

WTM highy specialized cable screening machine for the application of silver-plated copper tape, necessary for producing high frequency coaxial cables.

WTM sintering line for the polymerization of special cables (taped or extruded).

- Contact Information

- Business Proposals

Company:

W.T.M. SRL

Web site:

Address:

VIA AUSTRIA 12

City:

PADOVA (PD)

Zip Code:

35127

Social media:

Tag:

No business proposals uploaded

- Map

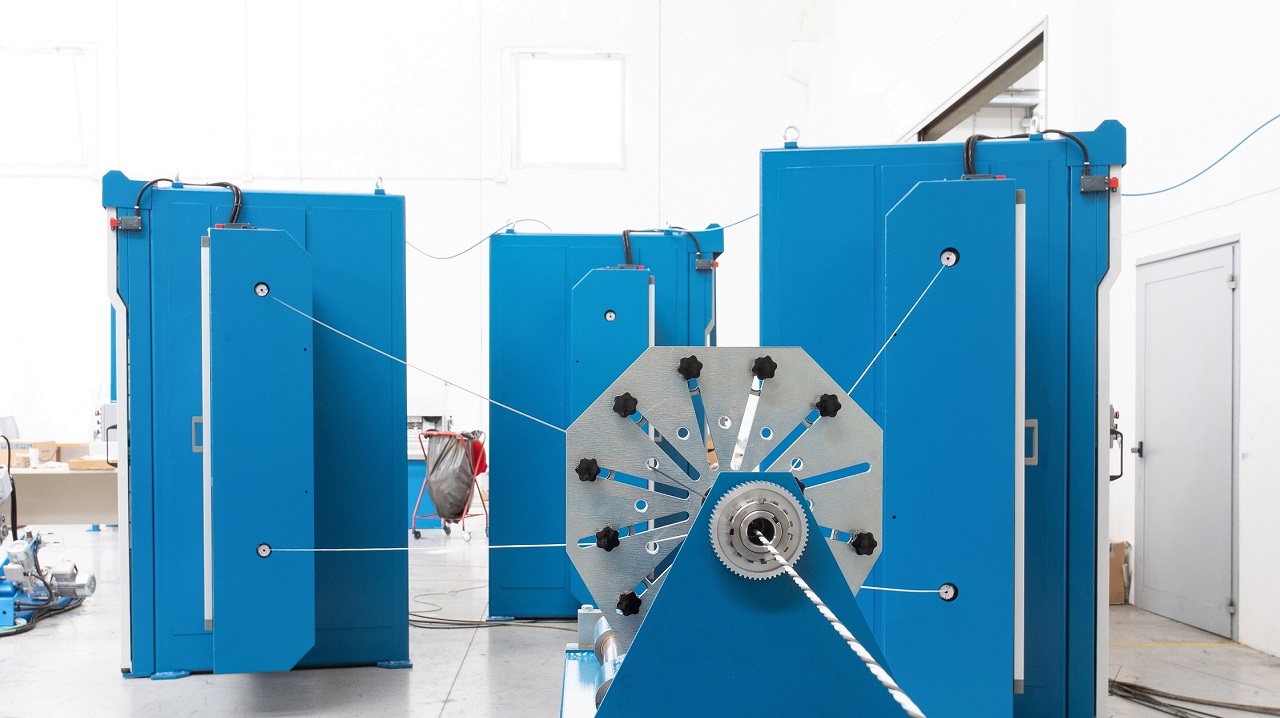

Cable Taping and Screening Machines

WTM designs and manufactures cable taping and screening machines for the production of a very wide range of cables.

The types of cables produced with these WTM machines and their application fields are many:

• aeronautic, aerospace and defence;

• coaxial, high frequency, instruments,

• automotive, industrial, automation;

• twinax, telecommunication, networking;

• building, safety, control;

• energy, motors, generators.

WTM taping lines apply almost all types of tape available on the market, using both cross-wound spools and pads: mica, polyimide, polyester, PTFE and ePTFE, silver-plated copper, aluminium, fiberglass, mylar, paper, TNT, and more.

The strong point of the WTM cable taping heads is the extremely precise and accurate management of the tape tension by means of the electronic dancer: it allows to obtain an excellent tape application on the cables even in the case of the most complex materials.

With horizontal or vertical layout, the machine configuration is studied according to the cable to obtain and to the Customer production needs, and it is further completed with all necessary devices, such as:

• heating ovens for performing the sintering process;

• visio system, WTM inline quality control system with camera;

• laser gauges and spark tester, for furthe measurements.

WTM produces also cable spinning lines, for the specific application of fibers and textiles, and splittable taping machines, that offer the advantage of having 2 production possibilities in a unique equipment.

WTM supports the Customers, analyzing the specific production requirements in the wide range of cable constructions, and suggesting the most suitable technical solution to obtain the best performing cable and the optimal production process.

Single-twist Cable Stranding Lines

WTM designs and manufactures single-twist stranding machines for the production of a very wide range of cables.

The cables produced with this type of WTM machines are characterized by extremely high flexibility, which is an indispensable property for the sectors of application:

• automotive;

• robotics;

• telecommunication;

• instruments;

• data transmission;

• energy.

WTM offers both single shaft and cantilever construction, depending on the dimensions of the reels required by the Customer:

• single-shaft design for reels from DIN 400 to DIN 1250;

• cantilever design for reels from DIN 630 to DIN 2000;

The design of WTM stranding machines is conceived for maximizing the quality of the final cable: the wire path is studied to avoid excessive bending angle on the single elements composing the cable and to ensure th absence of any residual twist. Moreover, the absence of rotating electromechanical devices (such as motors, encoders, etc) reduces the stress on critical components.

The wire tension control is very accurate, and it is managed by direct torque control or by WTM innovative rotating dancer. Furthermore, high precision in the stranding pitch in granted by the integration of the rotating capstan in the machine lay-out. Nevertheless, WTM stranders reach 1000 RPM.

In addition to the stranding process, WTM manufactures also rigid stranding machines, dedicated to the production of twinax and data transmission cables: each stranding bay holds 4 or 6 reels, up to DIN 400.

WTM completes the rage of machines for this specific production process with backtwist cable pay-offs. With single, double or even triple reel position, from DIN 400 to DIN 800, the backtwist pay-off units feed with high efficiency the cable stranding lines. WTM rotating dancer perfectly controls the wire tension during the unwinding process, guaranteeing a regular detorsion without any interference.

WTM supports the Customers, analyzing the specific production requirements in the wide range of cable constructions, and suggesting the most suitable technical solution to obtain the best performing cable and the optimal production process.

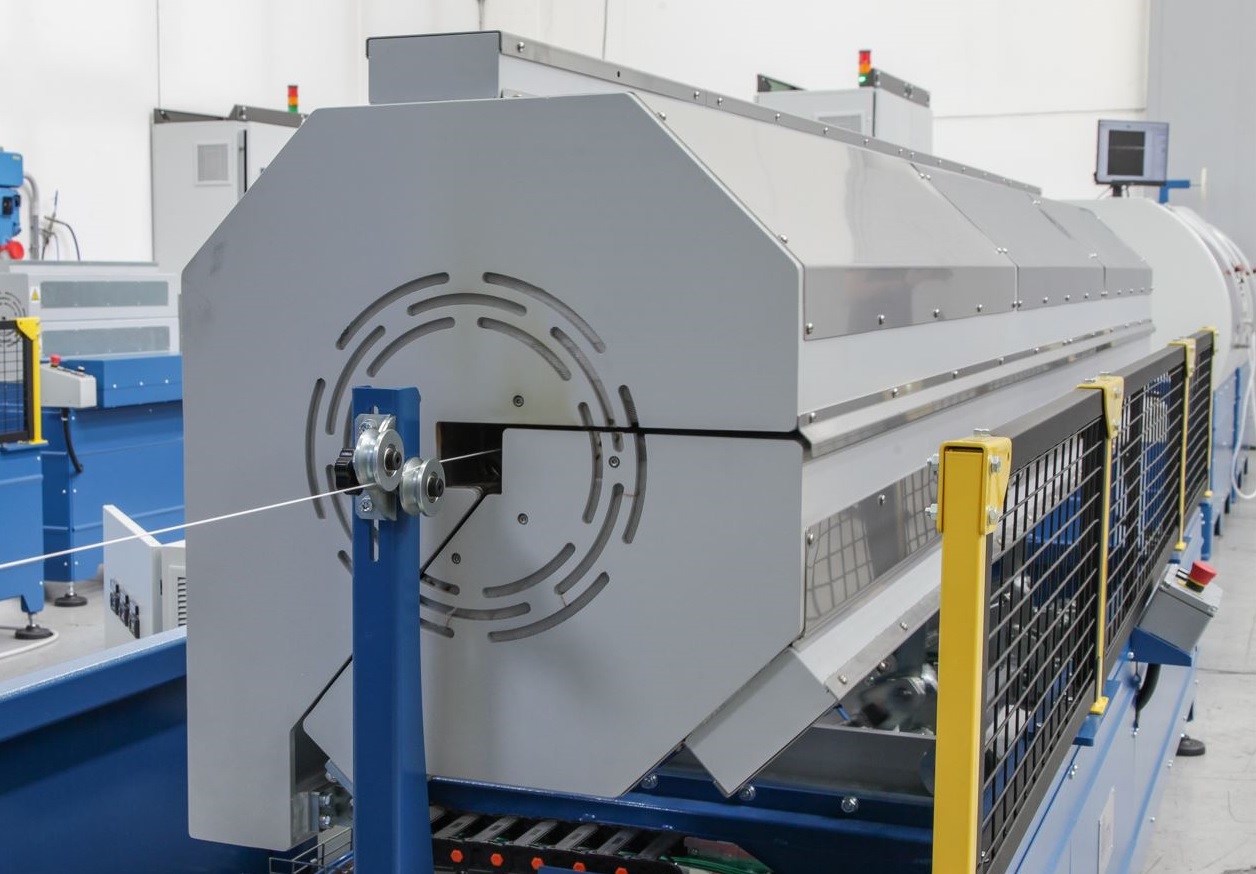

Cable Heat Treatment Systems

WTM completes its range of machines for producing high-quality cables with heat treatment systems: vertical and horizontal sintering ovens, with related cooling units.

The strong point of WTM in cable sintering is the possibility to choose among different heat treatment technologies, depending on the Customer's specific production requirements:

• infrared technology, offering optimal sintering process and improving the oven efficiency, together with reduced maintenance due to dirt;

• hot air technology, that has the advantage of avoiding the thermal layers effect by continuously circulating the air inside the heating chamber;

• mixed technology, giving the possibility of mxing the 2 effects by adjusting their percentages and optimizing the process.

The heat treatment process is completed by the cooling units, which can be by means of water or compressed air.

Moreover, the horizontal furnaces can be of different lengths and placed in succession, according to the characteristics of the finished cable.

WTM supports the Customers, analyzing the specific production requirements in the wide range of cable constructions, and suggesting the most suitable technical solution to obtain the best performing cable and the optimal production process.

Visio System: in-line Cable Quality Inspection

WTM has developed its visual control system for supervising the cable taping process: VIsio System, that with high-speed cameras acquires images of the tape application process on the conductor; these are then processed by a specifically developed software, which extrapolates numerous production data.

The main functions of the Visio System are therefore:

• magnifying function, to be able to visually monitor the taping process in real time;

• measuring function, and the measurement data obtained are displayed on the monitor (taping pitch, angle, tape edges, CPK indexes, etc.);

• further statistical analysis, using the WTM data analysis software, which post-processes all the collected data and performs further statistical analysis (Statistical Process Control and Fast Fourier Transform.

WTM supports the Customers, analyzing the specific production requirements in the wide range of cable constructions, and suggesting the most suitable technical solution to obtain the best performing cable and the optimal production process.