- About us

- Company details

COMEZ is a first-rate company in the technology of crochet and warp knitting machines and it's a member of the Jakob Müller Group.

Our knitting machines are used for the production of narrow fabrics (lace, ribbons, bands) both for classic sector, such as passementerie, fancy yarns, underwear, and for technical fields applications, like sport bands and 3D fabrics, technical nets for automotive, fishing, construction and agriculture, orthopaedic and medical fabrics, house cleaning fabrics and many more.

The COMEZ production range includes:

* Crochet knitting machines, with numerous models, both mechanical and electronic;

* Electronic single and double needle bed warp knitting machines;

* Accessory machineries;

* Software programs for pattern programming, both for crochet machines and warp knitting, and for production control.

COMEZ offers several services:

* Production of prototypes, special executions

* Global sales

* Global service and spare parts for locally manufactured machines

* Training centre

* Worldwide helpdesk

* Machine demonstration showroom

Year of establishment:

1953

Number of employees:

FROM 50 TO 99 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2022

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of other general-purpose machinery

Manufacture of machinery for textile, apparel and leather production

Manufacture of textile machinery

- Videos

- Catalogue

General presentation of the applications for Comez crochet and warp knitting machines. You can produce an extensive range of fabrics for a variety of applications, both for apparel and technical uses: UNDERWEAR, PASSAMANTERIE, FASHION, SPORT, SHOE UPPERS, TECHNICAL, ORTHOPAEDIC AND MEDICAL, HOUSE CLEANING, AUTOMOTIVE, GEO AND INDUSTRIAL TEXTILES

High efficiency circular knitting machine for chainette cords and ear loops for face masks. 1700/20 is a high efficiency machine for the production of chainette cords (“tripolino”), widely used in passementerie, in the medical and trimming industry, for knitwear and accessories. This machine is especially suitable for the production of elastic ear loops for protective face masks, both disposable and reusable. The 1700/20 machine can be equipped with a bobbin creel with 40 positions and a finished product collector with 2 rollers for high boxes.

MULTIAXIAL/EL-32 is an electronic double needle bed warp knitting machine for the production of technical articles and multi-axial fabrics.

CT-8B/600NET is an electronic COMEZ crochet knitting machine for the production of nets, fabrics with locked stitch, in particular for technical applications.

COMEZ ACOTRONIC with special configuration for the production of complete face masks. This electronic crochet knitting machine, equipped with long throw device, produces reusable face masks including elastic bands. COMEZ ACOTRONIC con una speciale configurazione per la produzione di mascherine protettive. Questa macchina a crochet elettronica, equipaggiata con un dispositivo a lunga tramata, può produrre mascherine complete di elastici.

No documents uploaded

- Contact Information

- Business Proposals

Company:

COMEZ INTERNATIONAL S.R.L.

Web site:

Address:

VIA ENRICO FERMI 5

City:

CILAVEGNA (PV)

Zip Code:

27024

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

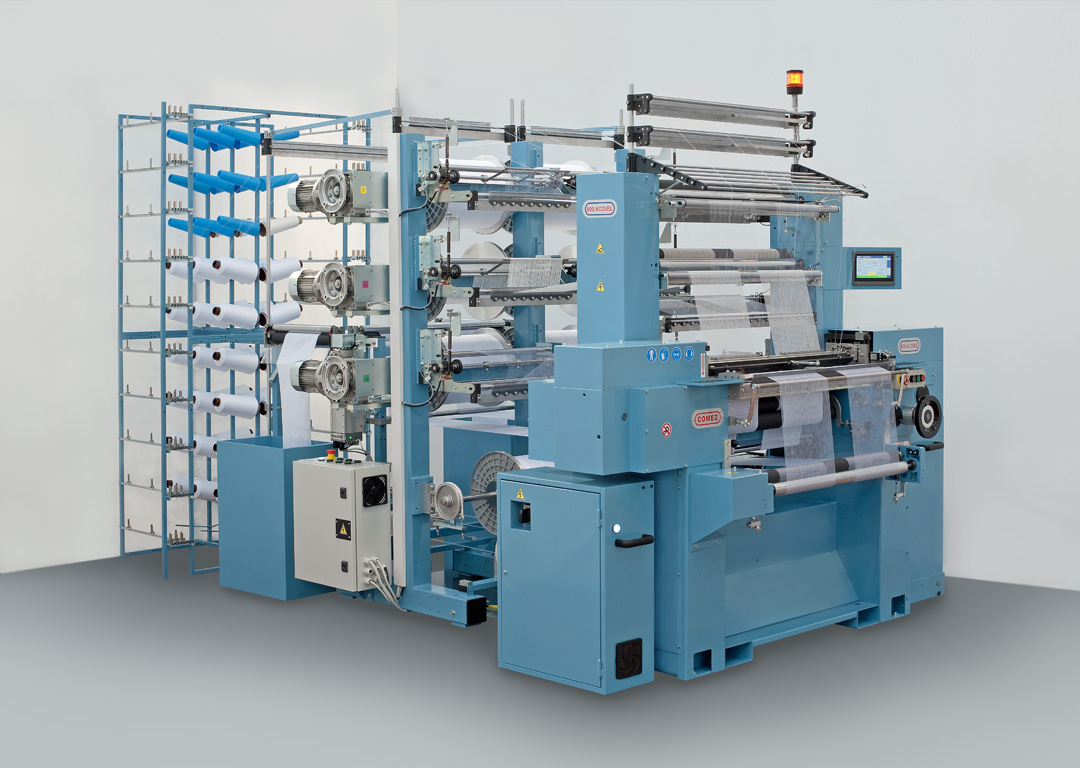

DNB/EL-32-12B: electronically controlled warp knitting machine with double needle bed for technical and garment textiles

DNB/EL-32-8B • DNB/EL-32-12B is an electronically controlled warp knitting machine with double needle bed for the production of technical and garment textiles. The machine is equipped with 8 or 12 guide bars with electronic control and with 2 knockover bars. Any type of yarn can be processed according to the machine gauge: natural fibre yarns such as wool and cotton; synthetic yarns; special yarns such as aramid, glass fibre yarns, metallic yarns; high tenacity PP and PES yarns, monofilament yarns, etc. Programmable electronically driven feeders and take off rollers allow a variable stitch density and tension setting of the elastic yarns in warp and weft within one single product. Two needle beds and the guide bars allow the production of double face structures, i.e. both sides of the fabric look identically. The two needle bed technology furthermore allows the production of 3-dimensional structures, like nets in flat or tubular version - both elastic and rigid. The distance between the two needle beds is adjustable up to a maximum of 20mm. USER BENEFITS: • Higher efficiency: reduced working width allowing fast article change overs for small and long runs • Compact machine design with all integrated devices including the beam support • Fluid movement of the machine’s knitting mechanisms. APPLICATIONS: • Technical textiles such as nettings, geo textiles and industrial fabrics) • Medical textiles such as nettings, bandages, dressings and disposable pants • Shoe uppers • Garment textiles

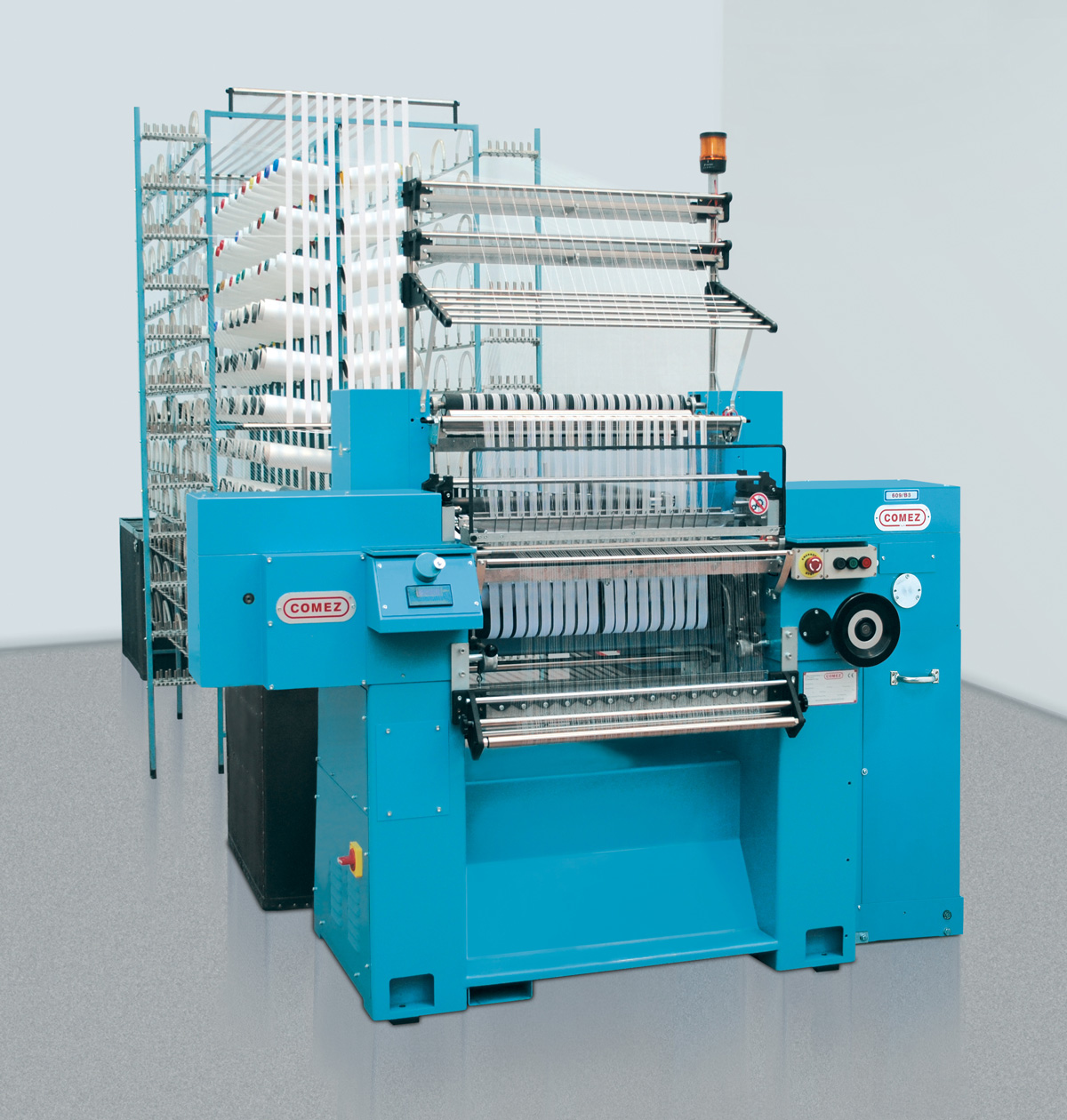

800 ACO/EL: Hybrid crochet knitting machine with electronic control of yarn tension and stich density regulation for narrow fabrics with lock-stitch structure

800 ACO/EL is a crochet knitting machine with electronically controlled yarn tension and stitch density regulation for the production of elastic and rigid fabrics and tapes as well as for products with lock-stitch structure ADVANTAGES FOR USERS The compound needle makes the machine highly versatile as it allows the processing in the warp – in addition to classic synthetic yarns (polyester, polyamide, polypropylene) – of natural yarns (cotton, wool) and special fibres (aramid, fibreglass). It is equipped with 8 weft bars controlled by chain links, composed of links presenting an involute profile, allowing weft movements of up to 30 mm and allowing high operating speeds and low noise emission levels. As an alternative, two bars can be driven by the weft device for weft movements of up to 50 mm. The electronic operating system allows to choose different stitch density values on one single product as well as different values for weft feeding and elasticity. The yarn tensioning and the stitch density are programmed by our exclusive COMEZ DRAW 3 or SYSTEM.WIN PC textile software. Datas are transferred from a PC to the controller on the machine by means of an USB key. MAIN APPLICATION SECTORS: The machine offers a wide range of product options and applications such as: • Astrakhan with close loop • Articles for house cleaning • Furnishing ribbons and tapes • Sportswear ribbons • Medical and orhopaedic textiles (bodybelts, gauzes and bandages)

609/B8 : high efficiency crochet knitting machine for a wide range of elastic and non-elastic narrow fabrics

It is built with a modular system that allows application in an easy way of a great number of devices that only COMEZ offers, completing the basic machine and giving it a very high versatility. The versatility comprises: • a wide range of products that can be made, including laces, bands and ribbons, both elastic and non-elastic • multiple pattern possibilities, using the 8 weft bars and the chain links extensions • several gauges available, allowing many different types of article. In designing this machine, particular importance has been given to the easiness of use and accessibility, so that all operations for regulations and maintenance are facilitated. The particular features of the weft bars (protected by international patent) eliminate any vibrations of the thread-guides and avoid breakages of needles and of thread-guide tubes.

Web site

http://www.comez.com/en/underwear/

High speed warp knitting machine with double needle bed for sportswear accessories and technical articles

WARP KNITTING MACHINE WITH DOUBLE NEEDLE BED FOR THE PRODUCTION OF SPORTSWEAR ACCESSORIES AND TECHNICAL ARTICLES GENERAL FEATURES

The machine is equipped with:

• 3-roller feeder for non-elastic threads, with mechanical control

• Differential 3-roller feeder for non-elastic threads, with mechanical control

• Electronic speed variator INVERTER

• Shock absorber feet

• Warning light

• Work area safety device

• Finished product take-down rollers

• Automatic stop motions for incorrect product winding onto the rollers

• Automatic stop motions for thread breaks or empty cones

• Reed unit for oscillation thread guiding

• Standard supply package of consumables and accessories

The machine is equipped with 2 guide bars with mechanical control and can process any type of yarn, both synthetic and natural, according to the machine gauge. Mechanically driven feeders and take off rollers provide a variable stitch density and tension setting.

Two needle beds and the guide bars enable the production of double face structures, i.e. both sides of the fabric look identically. The distance between the two needle beds is adjustable up to a maximum of 5 mm.

USER BENEFITS

• Best consistency fabrics, difficult to obtain on single-needle bed machinery for traditional fabrics

• Very high productivity thanks to the operating speed along with the low stitch density value required by fabrics produced

• Higher efficiency: compact design and reduced working width enabling fast article change overs for small and long runs

APPLICATIONS

Wide range of articles, such as:

• Outerwear (scarves)

• Sportswear (ribbons applied to fabrics as binding)

• Fabrics for technical uses

ON REQUEST

• Customized devices for rolling up or plaiting the fabric outside of the machine

• Some products require thermofixation to be applied to the machine

Web site

https://www.comez.com/en/sport/

High speed circular knitting machine for chainette cords

High performance machine for the production of any chainette cords, to be used in passementerie as well as ear loops for surgical face masks

The 1700/20 machine is suitable for the production of any tripolino, whether for passementerie, knitwear production, accessories and in many other sectors including the medical field. This machine is especially designed for the production of elastic, resistant and soft to the touch chainette cords. The specifications of these elastic cords enable easy connection to the fabric and make them ideal as ear loops for protective face masks, both disposable and reusable.

Main benefits for users

- Wide number of applications. Hole diameter and quantity of needles can be defined according to each sample

- Easily interchangeable knitting heads. Needle cylinders are available with 4, 6, 8, 12, 16 and 24 needles each

- Possibility of processing all yarn types. Latch needles allow natural, man-made and synthetic yarns to be employed