- About us

- Company details

EQUIPMENT THAT MAKES THE DIFFERENCE - We design and supply equipment with a high technological content that represent a concrete solution to the complex problems that are common in the world of plastic injection molding. Satellite injection unit, manifold, rotary table, sequentials.... Everyone has different molding needs and we are here to listen and meet you, creating equipment which suit your needs (for example: “injection unit + rotary table + protective cage” etc…). After a in depth study, we help our customer in improving the entire production process.

Year of establishment:

1990

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2020

Export turnover:

0

Activities:

Manufacture of moulding boxes and moulds

Manufacture of general-purpose machinery

Manufacture of plastics and rubber machinery

Activities of agents involved in the wholesale of machinery and industrial equipment for use in industry and trade

Wholesale of machine tools

Wholesale of other various machinery and equipment nec

- Contact Information

- Business Proposals

Company:

DIVISIONE PRODOTTI SPECIALI SOCIETA' A RESPONSABILITA' LIMITATA IN FORMA ABBREVIATA "DPS S.R.L."

Address:

VIALE DEL LAVORO 4/I

City:

MONSANO JESI (AN)

Zip Code:

60035

E-commerce:

Tag:

No business proposals uploaded

- Map

Satellite Injection unit

It allows to produce products in two or more components on traditional presses. The device can be easily adapted to each press and moved from one work island to another. It allows the programming of all injection settings (speed, pressure, times, backwash, back pressure)

Web site

https://dps-srl.biz/it

Sequentials

Management system for the opening of the shutter nozzles in a sequential way, for objects of important dimensions or complex geometries. The settings by means of the software offer the use of the system in two ways: related to position of the plasticizing screw or according to a set intervention time

PLUS:

Maximum of 4 openings and 4 closures per cycle

Control up to 30 moulds

Homogeneous and high aesthetic quality results

Web site

https://dps-srl.biz/it

MCS-NET

Equipment for managing from 8 to 128 independent circuits and adjusting the temperatures in the mould; a probe detects the temperature of the outgoing water and compares it with the set value determining the opening or closing of the pneumatic valve. The graphical interface with Ethernet connection in Windows has an unlimited memory capacity.

PLUS:

Achievement of optimal conditions in a very short time

Web site

https://dps-srl.biz/it

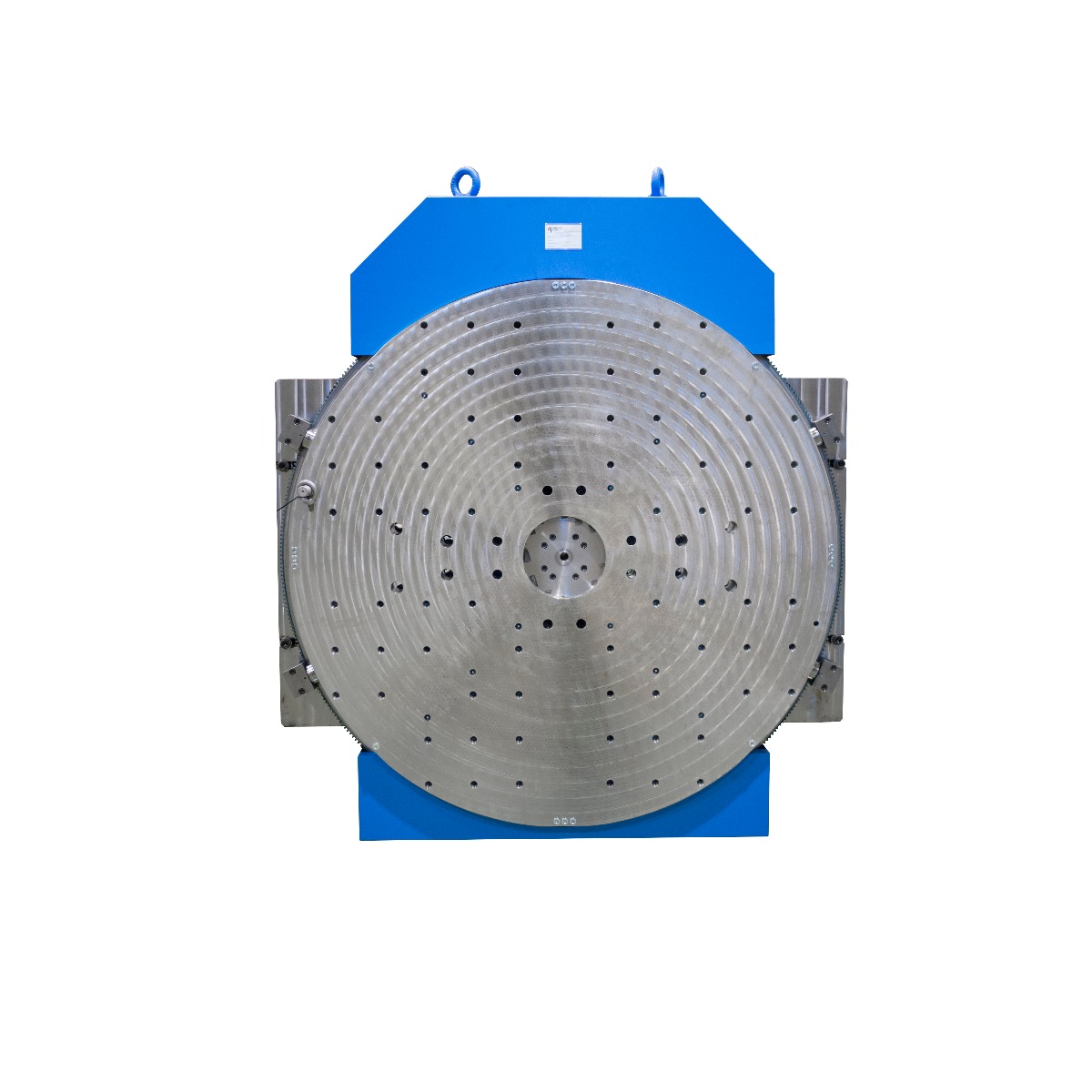

ROTARY TABLE

Rotating plate that can be installed on any type of press for the injection on the bi-material moulding. After the injection of the first material, the rotary table moves the mould and positions it so as to also inject the second material.

PLUS:

Applicable on each press with hydraulic jack

Three independent circuits for mechanical movements: water, air or oil pressure

No scratches

Web site

https://dps-srl.biz/it

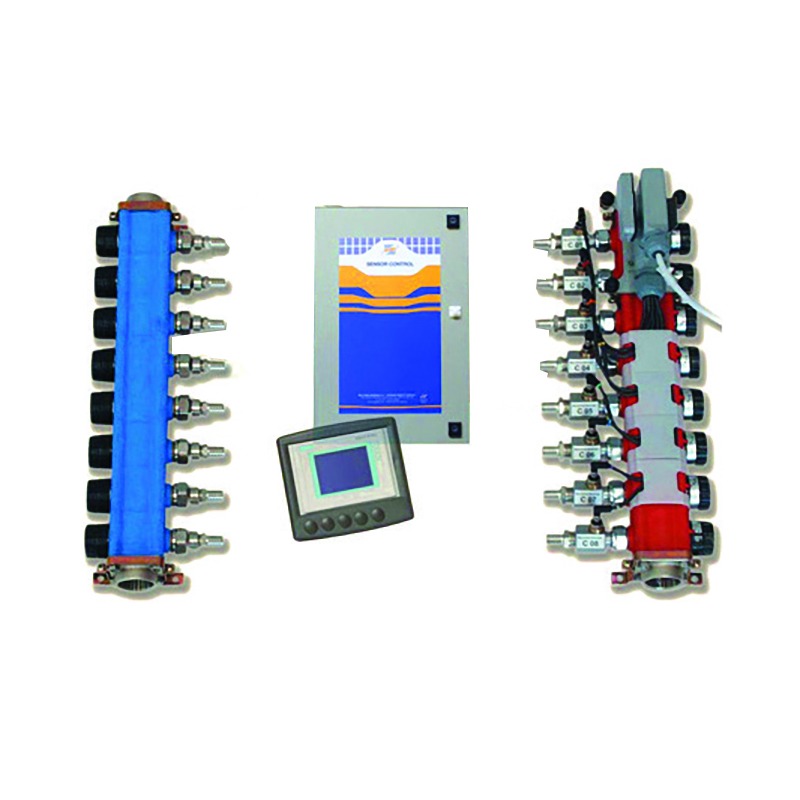

SENSOR CONTROL

Modular manifolds designed to regulate the water flow in the cooling circuits with a remote viewing of the output temperatures of each individual circuit which is also able to highlight any malfunctions of the systems.

PLUS:

Flow regulation in relation to the detected temperature

Verifiability of the channel status

Application on the press plane or on the mould

Web site

https://dps-srl.biz/it