- About us

- Company details

Tropical Food Machinery SRL is an international company with headquarter and workshop in Busseto (Parma - Italy), a second headquarter and production center in Pouso Alegre (Brazil), two controlled industries for the processing of tropical fruit in northern Brazil, Flora and Mirca. Tropical Food Machinery owes its reputation to the independent design and construction of complete plants for fruit and tomato processing. It develops a range of "turn-key" lines, from receiving to filling, with a capacity ranging from 200 kg/h to 50 t/h. Designed for large industry and for small producers and cooperatives, they can cover the market at 360°.

The production of both technological poles is tailor-made to suit the customer's needs; the improvements made on the field and are then integrated in the newer projects. Tropical Food Machinery deals with the construction and commissioning of the machinery without intermediaries. This verticalization of production guarantees control over quality and unparalleled productive speed, as well as creating a strong sense of community within the company’s workforce. Tropical Food Machinery offers the customer the ability to connect by electronic means and receive assistance remotely for their plant: this way, our “vertical” style includes buyer’s assistance.

Year of establishment:

2016

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2018

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of machinery for food, beverage and tobacco processing

- Contact Information

- Business Proposals

Company:

TROPICAL FOOD MACHINERY S.R.L.

Web site:

Address:

VIA STRADIVARI 17

City:

BUSSETO (PR)

Zip Code:

43011

Social media:

Tag:

No business proposals uploaded

- Map

EXTRACTION LINES

Tropical Food Machinery manufactures units for feeding, sorting, pulp separation, thermal and enzymatic treatment, refining and proposes special solutions of single and multi-fruit processing lines. In addition, TFM’s lines start from very low working capacity (200 kg/h) until 50,000 kg/h with different level of automation

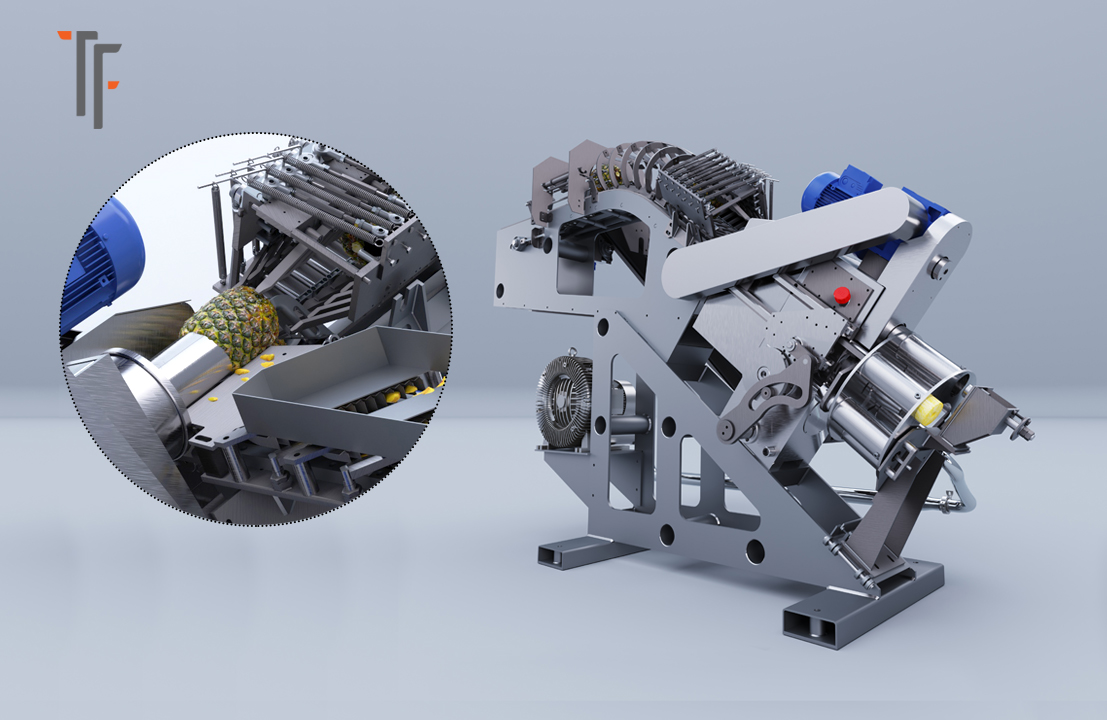

GINACA

This machine is capable to automatically form cylinders from pre-calibrated pineapple fruits. Tropical Food Machinery provides full solutions for pineapple-derived products: Cored cylinders - Slices in syrup Cubes - tid-bits in syrup. The high quality of products made through TFM equipment allows for the export to international markets

ASEPTIC FILLING MACHINES

Tropical Food Machinery can offer complete filling units according to the type of marketing and logistics: aseptic filling units for 200 and 1,000 L bags, aseptic filling units for small bags, filling nit of stand-up and flat pouches, filling in bottles, filling cans.

PASTEURIZERS AND STERILIZERS

Pasteurizers for sauces, juices, pulps and tomato. They are ideal for the treatment of whole pulps, concentrated juices and tomato sauce for frozen or hot fill bottling. TFM heat exchangers are designed with the most advanced technology, proof of that is the automated and computerized operation that allows extremely safe and reliable processing. We manufacture aseptic sterilizing and pasteurizing units for juice at high -low viscosity and diced product filled into bottles, pouches or tins. According to the product, we can offer a different kind of heat exchangers and pumps : single or multiple concentric tube in tube, tube nest, scraped surface, direct steam injection. The product is treated in complete hygienic and aseptic conditions.

EVAPORATORS

Tropical Food Machinery manufactures lines for the concentration of fruit juice or tomato. We manufacture lines from small capacity from 500 l/h to 50.0000 l/h of evaporated water, with different levels of automation from the simpler to the more complex ones.