- About us

- Company details

THE COMPANY

Aircom is based in the province of Turin, and has a 50 years experience in the production of automatic spray guns.

We design, produce and assembly all the automatic spray guns in our catalogue.

The products included in our range are automatic spray guns, accessories for spray guns and feed pumps.

VALUES

Every day we strive to offer you the highest quality products, keeping an eye on our core values: constant innovation, unique design, reliability of the products through time, sustainability and attention to the environment.

TRANSFER EFFICIENCY CERTIFIED

Our products are tested in advance to ensure the highest level of quality for the consumer: they have transfer efficiency certificates, attesting their quality during the atomization process.

SECTORS AND MATERIALS

We guarantee our products for the painting of leather, wood, plastic and metals; in recent years, we developed technologies that also work in the food industry, in the agricultural sector and in footwear businesses.

Some of the materials which can be sprayed are paints, pigments, glues, release agents, lubricants and much more.

ONLINE SERVICE

Our website is constantly updated with the latest technical innovations of the company: you can download the catalogue, navigate through our product pages, find all the information you need and request assistance.

We also provide our customers with tutorials for each product, explaining how to correctly use them or how to replace spare parts.

Year of establishment:

1973

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2020

Export turnover:

0

Activities:

Machining of metals

Manufacture of other general-purpose machinery n.e.c

Manufacture of other various general-purpose machinery nec

- Videos

- Catalogue

One of our core values is innovation: that is why we constantly improve our products and the way we create them.

Design is one of the key features of our spray guns: we believe it is important to pay attention to all the details of a product, especially during the design phase. We use 100% Made in Italy materials, which are certified and safe to use.

Reliability is fundamental during industrial processes: we guarantee high standards over time and an excellent transfer efficiency on all the materials.

Thanks to investments in technological innovation, research, development, valorisation of the human capital and promotion of an ethic and sustainable company culture, Aircom Original managed to become one of the most trustworthy companies in its field.

We provide our customers with tutorials on how to use our spray guns: from the first setting of the spray gun, to the replacement of spare parts, you can find all the information you need for every product.

- Contact Information

- Business Proposals

Company:

AIRCOM S.R.L.

Web site:

Address:

VIALE AMERICA SNC

City:

CASTELLAMONTE (TO)

Zip Code:

10081

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

ECO Spray Gun

The ECO spray gun was designed to reduce painting costs and to address the ecological aspect of industrial working and its impact on the environment.

We conceived a product able to work at very low atomization pressures with both great saving in painting products and a significant reduction in emissions into the atmosphere.

The gun body is made of three detachable parts so that only the part that is subject to most wear over time needs to be replaced.

50TH Spray Gun

The Aircom 50-TH is a high-quality automatic, reliable spray gun designed to meet the requirements of the most demanding markets.

It allows a conventianal gun to be converted to a HVLP gun by simply replacing the nozzle and head, while maintaining its outstanding finishing quality.

The spray gun is guaranteed in terms of durability and ease of maintenance.

LR Spray Gun

The LR spray gun, in addition to its ease of use and maintenance, offers versatility, excellent spraying quality and a low overspray.

Aircom LR spray gun is highly adaptable for different types of machining, meeting many market needs.

Its innovative design in the head-rod-nozzle kit and in the inside of the gun body allows an easy maintenance when replacing the spare parts.

QCC Quick Color Change

The QCC color change block allows you to make a product change on a set of guns by going from one process to the next without having to stop the production of the system.

This device, made with nickel-plated brass body and anodized aluminium covers, is characterized by 3 pneumatic actuators that enable passage on the colour ring “1” or “3” and solvent “2”.

Appropriately interfaced with the control unit, the Aircom QCC allows, in the various operating modes, to wash and/or load the circuit not connected to the gun power supply, resulting in a considerable saving of time by being able to carry out this operation in “shadow time”.

During the colour change phase, there is a rapid washing of the nozzle and the spray head of the gun, then moving on to the next programmed processing enabling the previously loaded circuit.

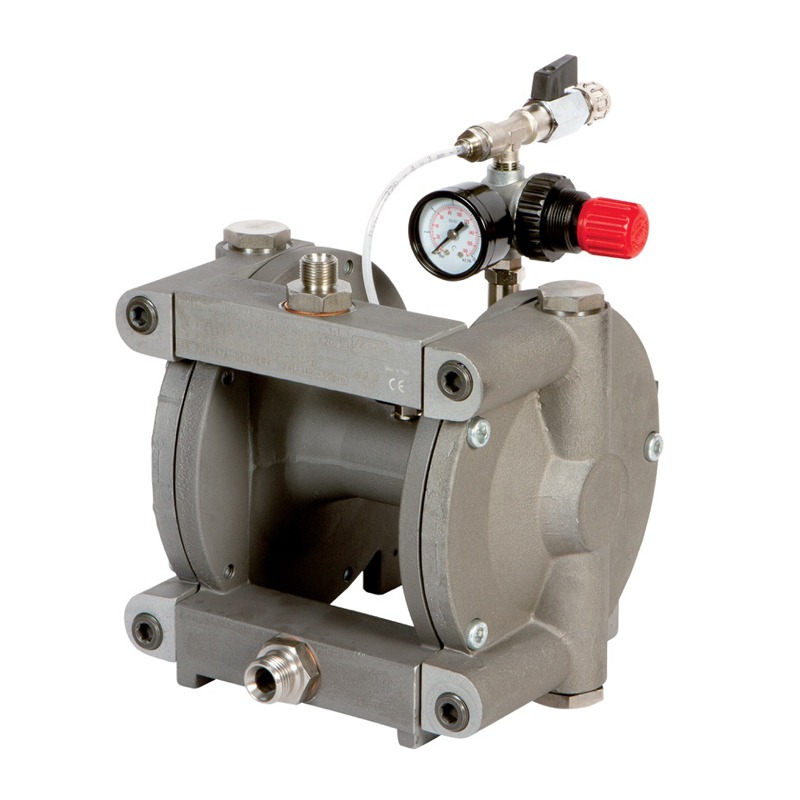

AST 24 Pump

Aircom AST24 is a double diaphragm pump suitable for water- or solvent-based products, enamels, lacquers, dyes, undercoats, glues and adhesives.

BODY AND HEADS

They are made of anodized aluminium and heat-treated to offer greater mechanical strength.

HOSE AND DIAPHGRAM

The intake and outlet hose fittings are made of stainless steel. Special diaphragms can be mounted for products requiring temperatures up to 80 degrees centigrade.

CONTROL VALVE

In the event of stalling, the pump control valve can be rearmed manually. Fluid can be delivered already at 1.5 bars.