- About us

- Company details

Ortelli Technologies is an Italian company officially founded in 2014 at the behest of the current CEO Maurizio Ortelli, who managed to carry out a pioneering project in the early 90s following a particular request from a well-known multinational to whom the first prototype was then sold.

Year of establishment:

2014

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 250.000 and 500.000 Euro

Reference year of turnover:

2023

Export turnover:

From 250.000 to 750.000 Euro

Activities:

Manufacture of measuring testing instruments, clocks and watches

Manufacture of other instruments and appliances for measuring and testing nec

Manufacture of plastics and rubber machinery

Activities of agents involved in the wholesale of photographic and optical equipment

- Videos

- Catalogue

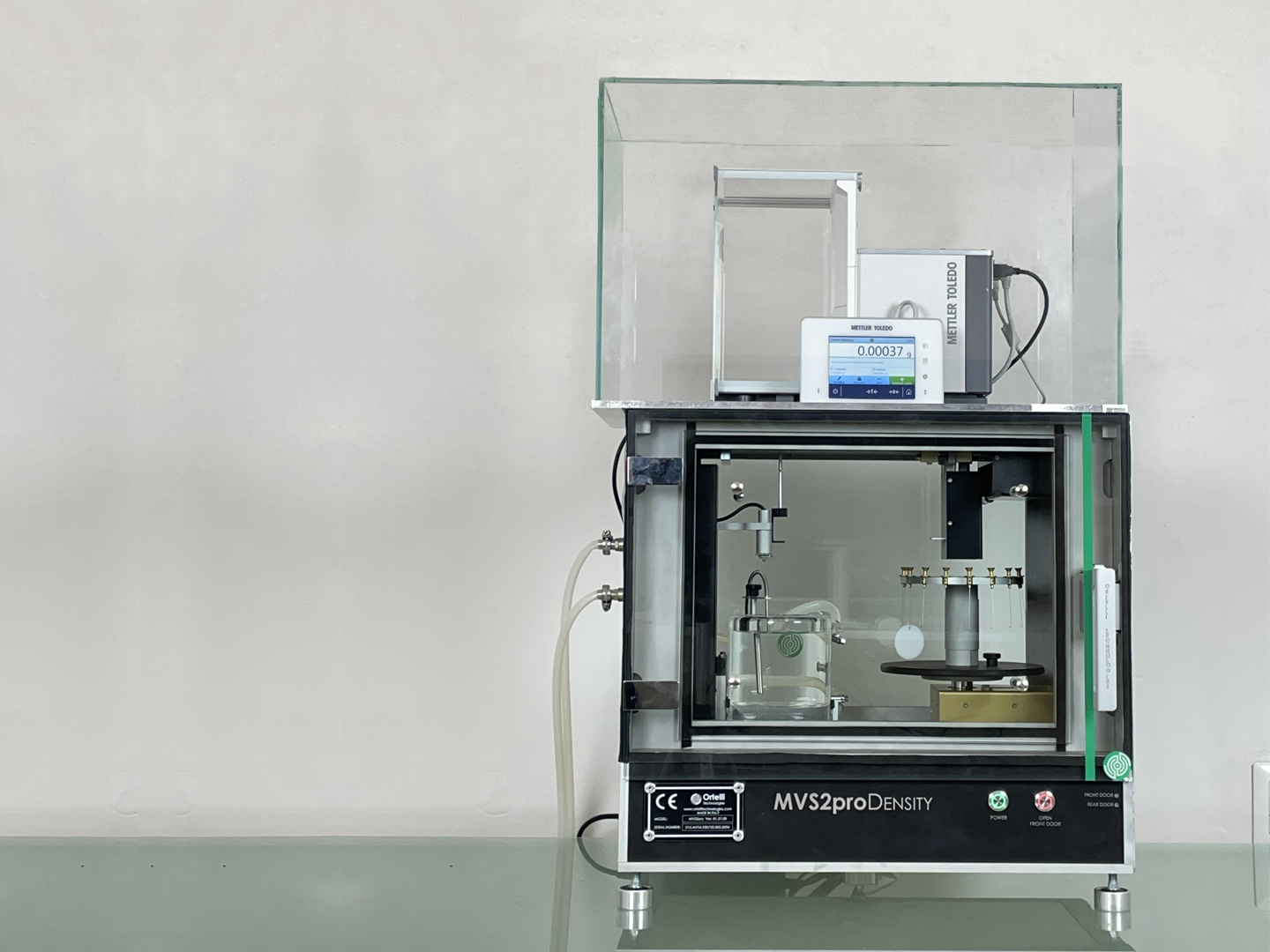

How improve quality control of solid material? MVS2pro Density is an Innovative and fully Automated system which to obtain Quality results quickly with accuracy and precision. A true revolution for measuring the density of all Polymers (such as rubber and plastic)and gems with a simple click and following exaclty the ISO 1183 regulation. How it works? ◼Step 1 - the autosampler brings a sample closer to the measuring system ◼Step 2 - the sample is measured in air by a Mettler-Toledo balance ◼Step 3 - the sample is dipped in the liquid ◼Step 4 - the analytical balance takes the measurement ◼Step 5 - the Orelli software processes the obtained data ◼Step 6 - the results are shown on the screen in few seconds

Density in 2 Minutes - MVS2pro Measurement demo

In questo webinar Maurizio Ortelli, CEO di Ortelli Technologies, in collaborazione con Mettler Toledo, presenta gli aggiornamenti e le soluzioni per la misura della densità dei materiali soldi non porosi con particolare attenzione alla norma che regola questa misura a livello internazionale, la ISO 1183 parte 1 e focalizzandosi su MVS2pro Density, un sistema completamente automatico che, collegato ad una bilancia analitica Mettler alla quinta decimale, permette in brevissimo tempo di misurare con accuratezza e precisione la densità dei polimeri termoplastici non porosi.

- Contact Information

- Business Proposals

Company:

ORTELLI TECHNOLOGIES S.R.L.

Web site:

Address:

VIA PISTOIESE, 601

City:

PRATO (PO)

Zip Code:

59100

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

MVS2pro Density System

MVS2pro is a robotic system for the determination of the Density or Standard Absolute Density (MVS) of solids by means of the hydrostatic push principle suitably corrected to obtain the result expressed in the MV (S) unit. MVS2pro determines the density in a fully automated cycle that replaces the old system used for this measurement, the Gradient Columns method, which is characterized by typical human errors and slowness in the measurement, as well as for the large measurement uncertainty that a manual system brings with it and which also affects the truthfullness of the data produced. The MVS2pro system is seamlessly integrated into the ISO9001 quality standard process. It is already supported by all control procedures for measurements performed using 5 different types of standards:

-1 certified glass density standard,

-1 certified mass standard,

-1 certified volume standard,

-1 polymer density standard,

-1 temperature standard (certified thermometer ).

All integrated into a statistical control plan of controls to check the validity of the analytical determinations of the samples.

MVS2pro Density System provides continuois, realt-time material density measurements with an accuracy of ± 0,01%. It has been designed for easy integration with existing control systems and is compatible with a wide range of industrial protocols.

Thanks to the precise, accurate and constant control of material density, MVS2pro improves the efficiency of production processes, minimizes material waste, ensures compliance with quality standards, guaranteeing uniform and high quality final products.

The system has an autosampler with a maximum of 16 samples and/or standard of density mass or volume and it makes the measure of a sample in about 120 sec; it is also equipped with an analytical balance which can vary in precision and accuracy based on customer needs.

Web site

https://ortellitechnologies.com