- About us

- Company details

We produce dosing, filling, labelling and capping machines, complete industrial lines and many other typologies of industrial machines for the food and beverage, cosmetic, chemical and pharmaceutical industries.

CM3 Engineering is a leading manufacturer of Filling machines: tabletop volumetric, automatic and semi-automatic, dosing and filling machines. The proper configuration for the product allows accurate dosing for any typology of product: liquid, semi-dense and dense. It is possible to dose products containing parts too.

Construction dosing units made of Aisi 304 are robust and space-saving, designed to be installed on manual, automatic and semi-automatic machines.

Parts in contact with the product are made of Aisi 316. Quick and easy to sanitise. Special gaskets are available for personalized CM3 ENGINEERING design.

Dosing volume adjustments are made by means of a graduate handwheel in the pneumatic version and through a touch-screen panel in the electronic version.

Micrometric adjustments and product suction and delivery are integrated.

Our standard dosing machines are designed to be heated according to the products’ requirements, for example for chocolate, butter or honey dosing. Adjustable temperature up to 120° C.

Year of establishment:

2020

Number of employees:

UP TO 2 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2021

Export turnover:

Not available

Activities:

Manufacture of packing and wrapping machinery

- Videos

- Catalogue

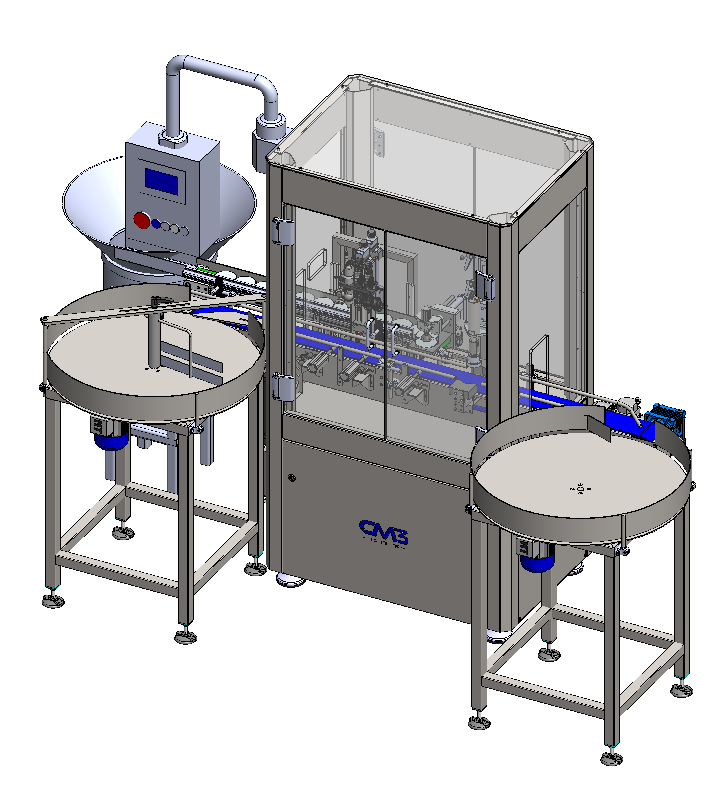

Dosing monoblock with thermosealing and capping monoblock with stainless steel base and protections in polycarbonate with access doors to the line and security checks via electrical microns. Electric panel with operator interface via touch screen panel and dedicated program where you can save the production recipes and adjust the operation of the machine.

Automatic Easy Line. Designed and designed for the food and cosmetic industry in a single unit, it manages dosing of dense, semi-dense and liquid products. Automatic capping with pick & place for positioning caps. It can be integrated with an additional doser to reach productions of up to 1,700 pcs. Specifically designed to reduce footprint in production.

Semiautomatic line for cosmetic sector. Recipe settings from touch screen panel that allows remote control of the line is able to handle different sizes in glass or plastic jars self-supporting.

Small sizes from 5 ml to 100 ml. This automatic line easily manages the filling in containers of different sizes with minority dosages.

Customized solution according to customer requirements. The line has been designed and manufactured according to customer needs. Specifically: - immersion dosing with peristaltic pump - weight balance with waste product system - operator station in front of touch screen for positioning caps - capping with easy format change - Front and back labelling machine - unloading with pusher in conveyor belt Specially designed to be adapted to the customer’s laboratory size

- Contact Information

- Business Proposals

Company:

CM3 ENGINEERING S.R.L.

Web site:

Address:

VIA PRA' BORDONI 46

City:

ZANE' (VI)

Zip Code:

36010

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

SEMI-AUTOMATIC FILLING, THERMOSEALING AND CAPPING LINE FOR CANNED FOODSTUFFS

Dosing monoblock with thermosealing and capping monoblock with stainless steel base and protections in polycarbonate with access doors to the line and security checks via electrical microns.

Electric panel with operator interface via touch screen panel and dedicated program where you can save the production recipes and adjust the operation of the machine.

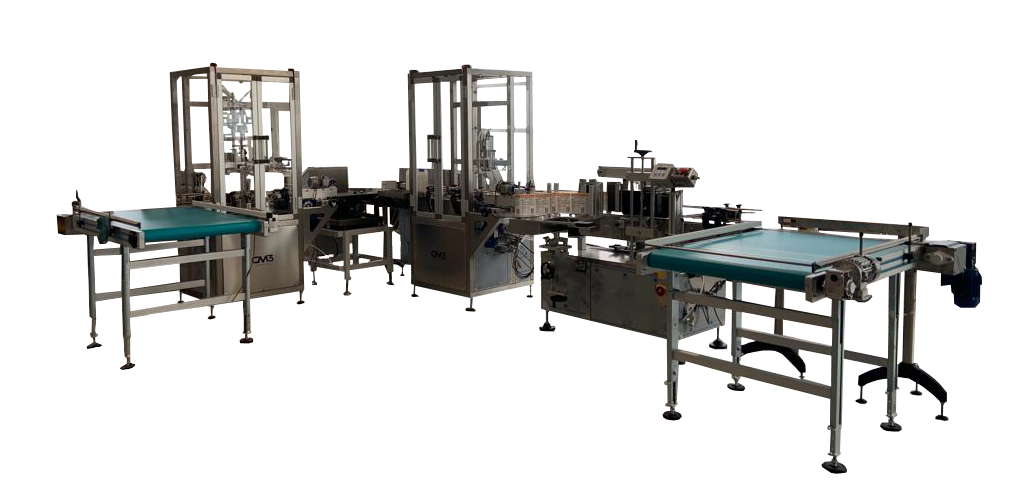

AUTOMATIC EASY LINE

The CM3 Engineering EASY line represents the ideal solution for the dosing and capping automation process where the customer's need is to have a lean, versatile and small-sized plant to start or improve the production process of one or more products.

The machine is equipped with a control panel with relative dedicated touch screen through which it is possible to start the machine, set the processing recipes and adjust its speed. The system can also be sold with the predisposition to be connected with the company management program in order to let them communicate.

The small size of the EASY line optimizes production spaces and for this reason it represents the ideal solution for small workshops, start-ups or product niches for which an hourly output of up to 1500 pieces per hour. It can also represent for the customer the next step to a previous bench solution supplied by us from which it is possible to recover both the doser and the capping head and implement them in an automatic system.

Automatic line for cosmetic sector

Built entirely of stainless steel, the line has been designed specifically to ensure the production of different types of products in multiple formats. The plus of this line is represented by the fast and practical format change and the washing system integrated in the dedicated program that allows a practical and suitable cleaning at the end of the working cycle.

Upgradeable at any time with the addition of additional dosing groups as well as automatic loading of the caps and positioning of the same via pick & place can be supplied with the integration of linear labeling machine to one, two or three heads.

Technical specifications:

Products: Liquids, semi-dense or dense for cosmetic application

Production: about 700 pcs/h depending on the loading speed of the caps by the operator

Packaging: glass jar, plastic or pet - self-supporting -

Caps: twist off/ pressure / screw

Serving size: 30 ml. to 5,000 ml.

Customized line for chemical industry with immersion dosing, weight balance and labelling machine

A customized solution made on specific request of the customer, suitable for treating foaming chemicals with immersion dosing.

The adapted dosing with peristaltic pump allows the passage of the product without coming into contact with steel parts. Weight balance with waste system produced after weighing and capping machine with descending head.

Construction quality of all 316 stainless steel components.

Double head labeller and batch printing expiration.

Ideal solution for hourly production up to 1,500 pcs

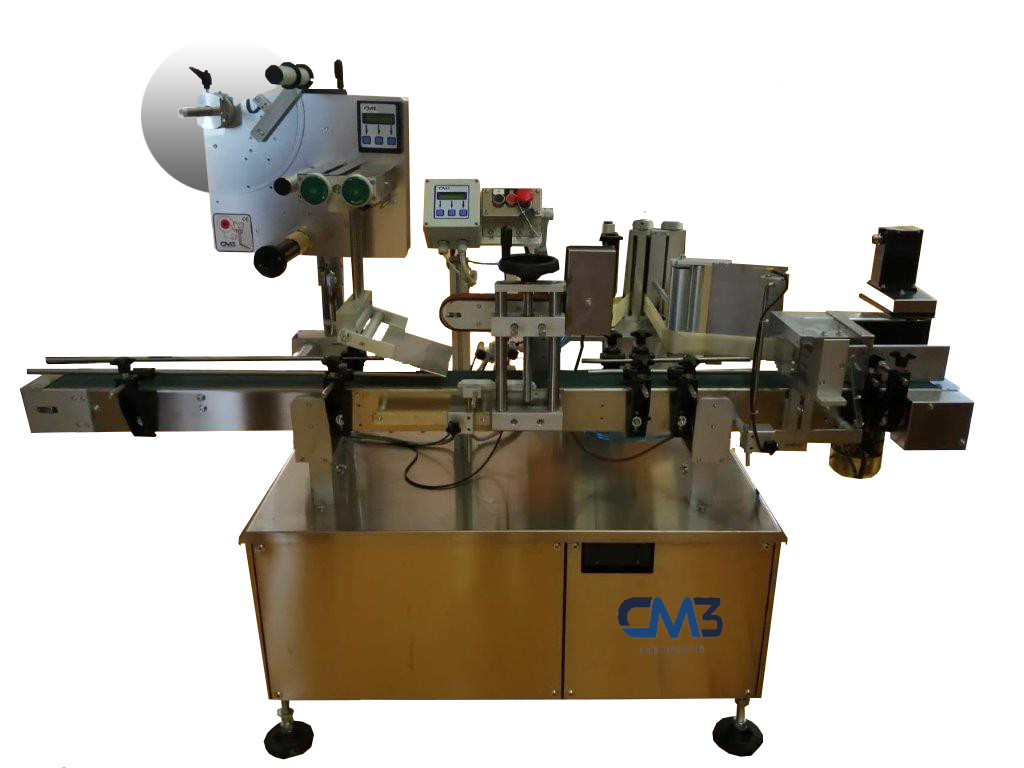

Linear labellers for productions up to 2.500 pcs

Our labellers can be sold individually or inserted in packaging lines of existing or our realization.

They can be supplied to one, two or three heads and integrated with printing systems for the expiration batch.