- About us

- Company details

WHO IS LOGINET?

Since 1997, Loginet Srl has been a leading reference in Italy in the field of industrial automation applied to the logistics of petroleum, chemical, and food products. The company was born from the combination of skills acquired over more than 30 years of experience and from the merger of historic automation companies, becoming a reliable technological partner for all businesses seeking safe, tailored and high-performance solutions.

Fluid Logistics is Loginet’s business unit specialized in developing automation systems for the supervision and management of the entire loading and unloading process of fluid, semi-fluid and dense products within depots and refineries. Our solutions also enable the automation of all handling operations involving tanker trucks, rail tankers and barges, ensuring operational continuity, centralized control and the highest safety standards.

The team guarantees top-quality work, with the expertise to follow each project through all phases: from preliminary consultancy to design, from implementation to post-sales support. All services can be provided individually or integrated into complete turnkey solutions designed to meet the specific needs of each client.

OUR APPROACH

The value of Loginet lies not only in the technology it develops but also in the consultative approach that guides every project. We work closely with our clients to fully understand their operational requirements, identify the most effective solutions, and build systems that combine high performance, safety, reliability, and economic efficiency.

Our technical team, continuously updated and trained, combines solid engineering skills with extensive operational experience, ensuring high-quality results and the ability to adapt to industry developments and regulations.

This spirit of innovation, together with deep technical expertise, makes Loginet – Fluid Logistics a solid and qualified partner for tackling the complex challenges of industrial fluid logistics and supporting major operators in the continuous improvement of their processes.

Year of establishment:

1997

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 0.5 and 2.5 million Euro

Reference year of turnover:

2024

Activities:

Repair, maintenance and installation of machinery and equipment

Warehousing, storage and support activities for transportation

Computer programming, consultancy and related activities

Other information technology and computer service activities nec

Logistics management consulting activities

- Videos

- Catalogue

No videos uploaded

No documents uploaded

- Contact Information

- Business Proposals

Company:

LOGINET S.R.L.

Web site:

Address:

VIALE MONZA 270

City:

Milano (MI)

Zip Code:

20128

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

Terminal Automation System NUOVO PETROL

Nuovo Petrol is a modular Terminal Automation System (TAS) designed for the supervision and full control of loading and unloading operations in depots and refineries handling petroleum and fluid products. The system streamlines tank storage management by providing a complete digital overview and guiding users —both operators and drivers — through the correct sequence of operational steps.

TAS Nuovo Petrol consists of multiple modules, which allow the implementation of a wide range of functionalities and controls. Modules can be selectively activated to address the specific requirements of each facility, ensuring a tailored solution for every operational scenario. Key modules include:

• Driver and vehicle identification

• Booking via totems and mobile app

• Load call and loading grid management

• Gate access control

• Weight control (tare and gross)

• Loading bay management, additive systems and tank level monitoring

• Integration with enterprise management systems (ERP)

• Business Intelligence and Data Mining

• Self pick-up point document handling

Benefits

Customization

The modular structure allows each aspect of the system to be customized, enabling the addition or removal of functionalities based on operational needs. This ensures that each client receives a solution perfectly adapted to their requirements and capable of evolving over time.

Flexibility

Nuovo Petrol is designed to integrate seamlessly with a wide range of existing and new devices, systems, and instrumentation. This guarantees the longevity of the investment, ensures smooth operation within existing infrastructure, and minimizes implementation time and costs.

Ease of Use

As a web-based application, the system can be accessed from any computer on the plant network. Updates and changes are applied centrally and automatically distributed to all connected devices, ensuring that users always operate on the latest software version. This reduces maintenance effort, minimizes downtime, and guarantees operational continuity.

Data Management

Using advanced Business Intelligence and Data Mining technologies, Nuovo Petrol continuously monitors and analyzes operational data. It provides real-time diagnostics, anomaly alerts, visualizations through interactive graphs, and detailed reports. All historical data is securely archived for future analysis, supporting informed decision-making and process optimization.

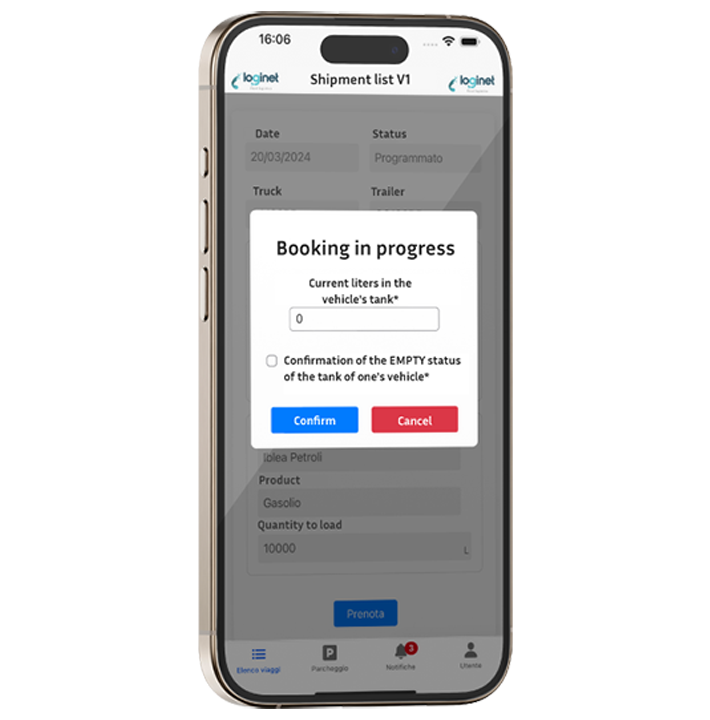

Mobile App FLUID

FLUID (Fast Loading Utility for Intelligent Distribution) is the mobile application developed by Loginet that empowers drivers to book tanker loading operations directly via smartphone, making the process simple, fast, and safe — all without leaving the truck upon arrival at the storage facility.

The app is cross platform (available for both iOS and Android) and integrates with the terminal automation architecture of Nuovo Petrol TAS.

FLUID offers the following features:

• Mobile load booking — Drivers can request and manage load bookings directly from the app as soon as they approach the facility.

• Real time updates — FLUID shows all scheduled shipments, updated parking availability, and loading call notifications.

• Trip overview — The app displays all trips assigned to the driver for the current day, giving a comprehensive view of daily activities.

• Direct navigation link — A built in link to navigation (e.g. Google Maps) guides drivers directly to the facility location.

• Instant notifications — Push notifications (and optionally SMS) alert drivers about call-to-load instructions and any updates.

Benefits

Faster, more efficient operations — The app streamlines the booking process, drastically reducing waiting times and optimizing the flow of tanker loading operations.

Improved safety — By enabling remote booking from inside the vehicle, FLUID reduces the need for drivers to exit the tanker truck in operational areas — minimizing accident risks and ensuring safer working conditions.

User friendly & intuitive — With an accessible interface designed for ease of use, drivers can handle bookings and check information with just a few taps, avoiding complex procedures or multiple systems.

Seamless integration with Nuovo Petrol TAS — FLUID is built to work in combination with the Nuovo Petrol automation system, ensuring smooth coordination of bookings, loading calls, gate control, and all depot operations managed by TAS.

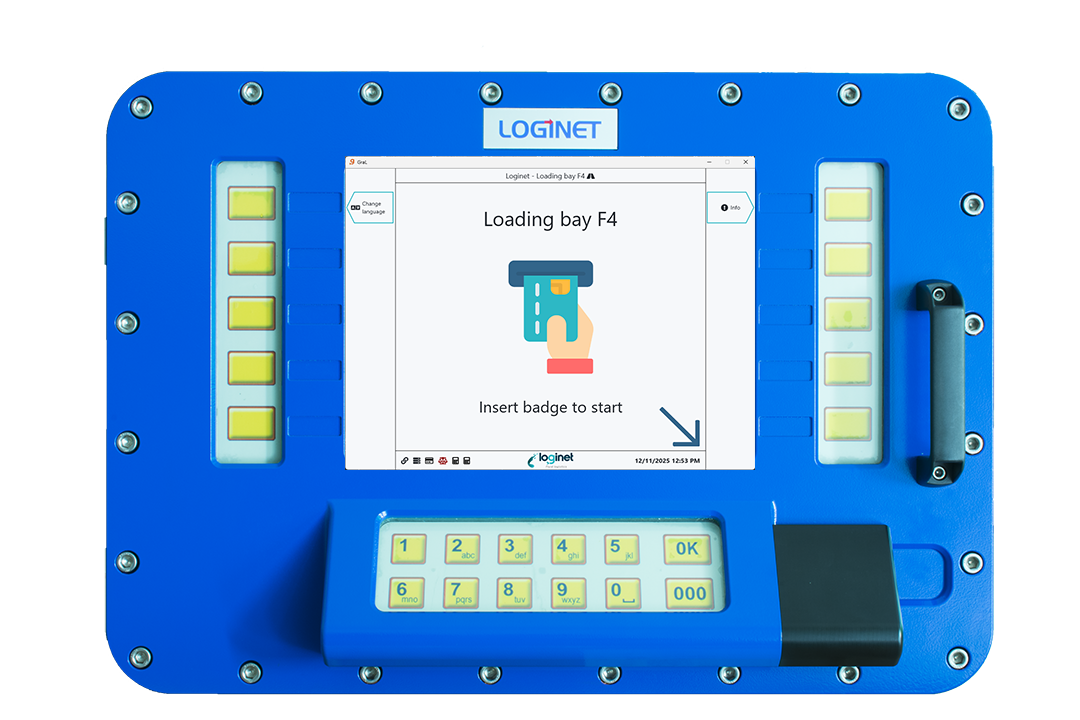

Loading Bay Terminal GraL

GraL is the bay terminal that constitutes the single interface between the driver, bay instrumentation, and Terminal Automation System (TAS). The driver will be able to control all bay loading operations through its large colour display and capacitive functional numeric keypad.

In fact, GraL delivers a modern, reliable, and adaptable solution for automating loading bays, combining flexibility, comprehensive control, and user-friendly operation to optimize safety, efficiency, and process transparency.

Its technical features are:

• Simultaneous control of up to 6 loading arms

• Management of additives, denaturation, and blending

• I/O management for automatic control of field devices, including overload protection, grounding systems, and vapor recovery arms

• Intuitive graphical interface for easy operation

• Customizable dispensing logic and control sequences

• Hardware self-diagnostics and alarm calibration

• Meter calibration and precision adjustment capabilities

Adaptability

GraL is highly flexible and configurable, making it extremely adaptable to different operational environments. It can function as an integrated module within the Nuovo Petrol TAS, connect seamlessly with third-party systems, or operate independently to manage stand-alone loading bays.

Wide Compatibility

The system is compatible with multiple flow computers simultaneously, even if supplied by different manufacturers. This allows depots to centralize control of all fluid dispensing operations efficiently, regardless of the hardware installed.

Operational Efficiency

GraL provides operators with an intuitive graphical interface that delivers clear, complete, and immediate guidance. Drivers have timely visibility of all necessary information, enabling precise and safe execution of operations. The system enhances operational efficiency, simplifies loading and unloading processes, increases control over activities, and ensures complete recording of events, alarms, and errors.

Badge Reader IBIS LT2

IBIS LT2 is a proximity badge reader that combines simplicity, reliability, and advanced functionality. It provides an easy-to-use solution for managing access and driver identification in tank storage facilities, supporting multiple operational points such as loading bays, weighing stations, and access gates.

Benefits

Versatility

IBIS LT2 is highly versatile, allowing driver identification across loading and unloading bays, weighing stations, and facility gates.

Seamless Integration

The terminal enables smooth and regulated access by controlling external devices, including barriers, turnstiles, and traffic lights, through its software interface.

Contactless and Secure

Equipped with a contactless badge reading system, IBIS LT2 enhances security while remaining simple to operate. Its standard serial interface allows integration with remote systems for centralized management.

Reliable Identification

When connected directly to the Nuovo Petrol System, the badge reader instantly verifies a driver’s authorizations for loading, unloading, or access, ensuring quick, accurate, and secure identification.

Direct Dashboard

Directional Dashboard is a software solution designed to provide comprehensive statistical analysis of all field data collected across fluid logistics operations. With an intuitive interface and secure, multi-platform access, the system enables fast, accurate and user-friendly data interpretation for informed decision-making.

The Directional Dashboard processes all key operational data, including delivered product quantities, number of completed loads, error occurrences, additive levels and tank inventory status. This information is transformed into clear, actionable insights through advanced analytical tools.

Benefits

Ease of Use

Featuring an interactive GUI, the Directional Dashboard allows users to quickly interpret operational information. The interface includes Synoptic pages that provide real-time visibility of multiple facilities, making monitoring immediate and intuitive.

Multi-Platform Accessibility

As a fully multi-platform solution, the dashboard is accessible from tablets and smartphones, enabling users to consult analyses anytime and anywhere. This enhances real-time decision-making and ensures continuous operational awareness.

Security

Data acquisition is managed through secure communication protocols and authentication systems, safeguarding sensitive information and ensuring that only authorized users can access the platform.

Process Automation

Automated data transformation and normalization reduce manual workload and minimize the risk of human error. This allows users to focus on strategic evaluations rather than data handling activities.