- About us

- Company details

ALBRIGI TECNOLOGIE – Italian engineering for advanced stainless steel systems. Over 35 years of industrial expertise.

For over thirty-five years, Albrigi Tecnologie has been designing and manufacturing stainless steel systems for the food, chemical, pharmaceutical, cosmetic, wine, oil, and biotech industries, with a strong focus on quality, process efficiency, and custom engineering.

Our extensive experience allows us to handle every phase of development, from the initial consultation to the final installation of fully integrated and ready-to-operate systems. We don’t just build tanks — we engineer complete, tailored solutions aligned with each customer’s process flow, product characteristics, and growth strategy.

- International scope, precision-driven mindset

Over the years, we have supported businesses of all sizes, from local producers to global manufacturers. Our systems are in operation across multiple continents, proving the consistency of our technical approach and the strength of our real-world know-how.

- Certified materials and meticulous design

We use only high-grade stainless steel, certified for food and pharmaceutical applications, and design systems that meet the most demanding international standards. Every project includes full traceability, complete documentation, and clear, user-friendly manuals. Our engineering team pays close attention to every detail to ensure reliability, low maintenance, and long service life.

- Smart innovation with practical value

We develop tailored technological solutions to streamline industrial processes: from intelligent sensors for fermentation control to thermal management tools and automation systems that reduce manual intervention and enhance traceability. Innovation for us means efficiency you can measure and trust, always with an eye on sustainability and the evolving digital landscape.

- A people-first approach

At Albrigi, people come before machines. Our designers, technicians, and skilled workers collaborate closely with customers, combining competence and care in every project. We believe that great results start with great communication — and we build accordingly.

- Choosing Albrigi Tecnologie means choosing a reliable and competent partner who understands your production needs — wherever you operate.

Year of establishment:

1989

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2001

Export turnover:

Not available

Activities:

Manufacture of fabricated metal products, except machinery and equipment

Manufacture of central heating radiators, steam generators and boilers

Manufacture of other tanks, reservoirs and containers of metal

Manufacture of other fabricated metal products nec

Manufacture of non-electric domestic appliances

Manufacture of machinery for food, beverage and tobacco processing

- Videos

- Catalogue

St. Jodern Kellerei Project: Space Optimization and Technological Innovation

Albrigi Tecnologie - Stainless Steel Tanks For Food, Chemistry And Pharmaceutical Industry

ANTARES Project for Domaines Sother – Innovation and Automation for a Cutting-Edge Winery

- Contact Information

- Business Proposals

Company:

ALBRIGI S.R.L.

Web site:

Address:

VIA TESSARE 6/A

City:

STALLAVENA GREZZANA (VR)

Zip Code:

37020

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

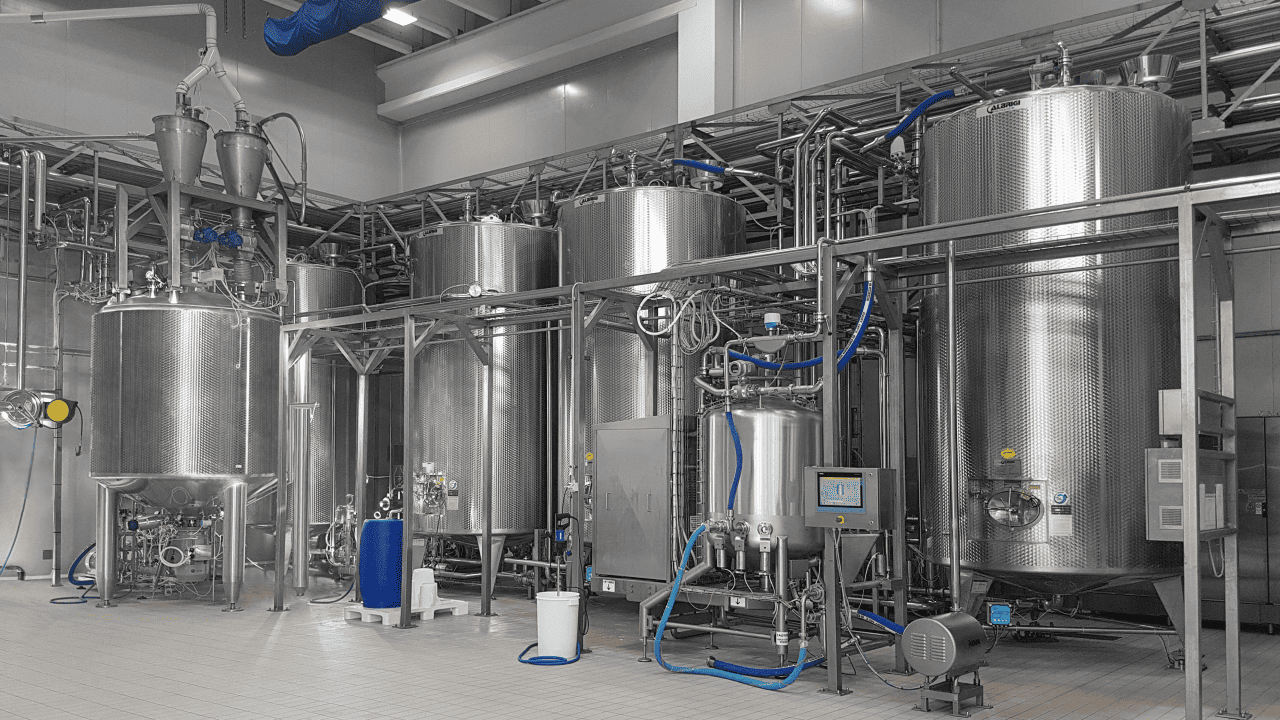

Stainless Steel Systems for Food Processing and Storage

In the food industry, where hygiene, safety, and traceability are non-negotiable, Albrigi Tecnologie specializes in the design and manufacturing of custom stainless steel systems for the processing and storage of liquid food products, including milk, fruit juices, syrups, vegetable oils, and food by-products.

Each system is engineered to facilitate effective and safe cleaning, with polished internal surfaces (High Clean Inside finish), hygienic connections, certified welds, and designs prepared for integration with CIP (Clean-In-Place) systems. Equipment is built to allow easy inspection and maintenance, ensuring operational reliability and long-term durability.

Albrigi’s product range includes process and storage tanks, mixers, fermenters, temperature-controlled vessels, and washing systems. Each unit is tailored to meet the specific product characteristics and production requirements of the customer.

All materials comply with current regulations governing materials and articles intended to come into contact with food, in line with both European and international standards for food safety.

The design philosophy combines compactness and functionality with technological solutions aimed at optimizing efficiency, reducing energy consumption, and enabling accurate monitoring and control of all production stages.

With a deep commitment to quality and attention to industrial design, Albrigi Tecnologie delivers high-performing, hygienically optimized systems that support the quality and integrity of food products—throughout every step of the processing cycle.

Web site

https://albrigi.com/en/alimentary

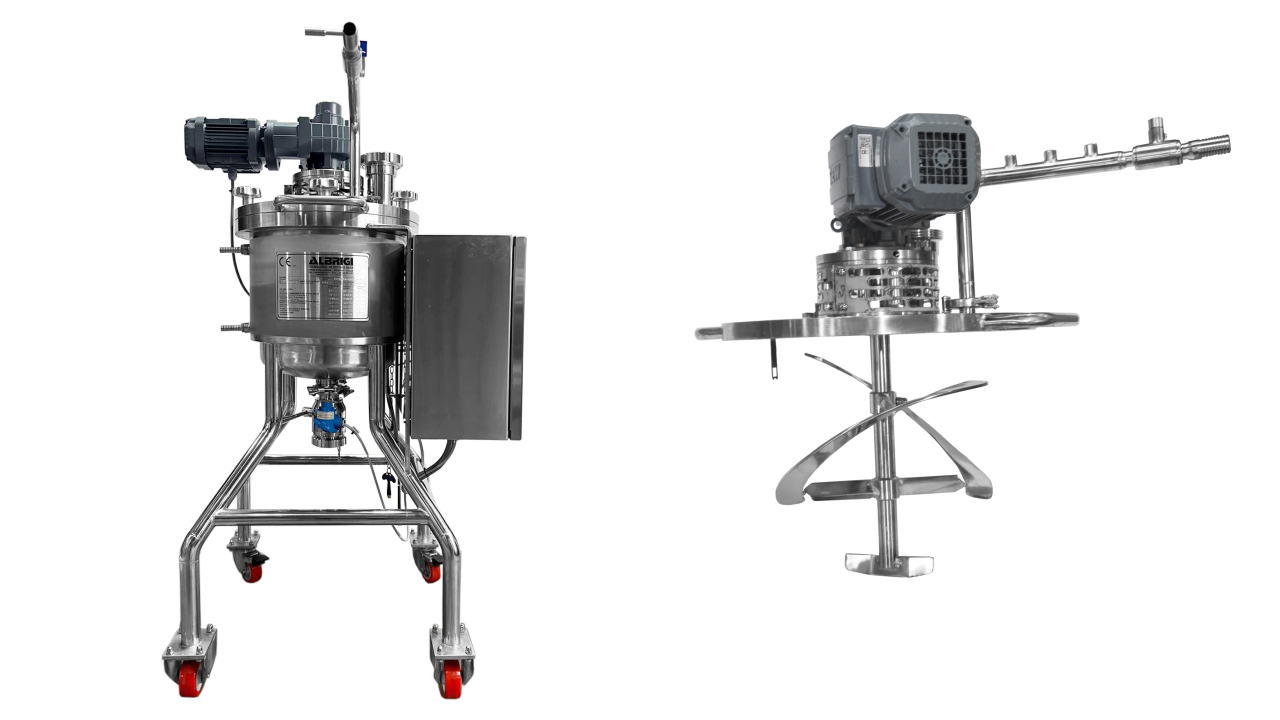

Stainless Steel Mixing Systems for Liquid and Semi-Liquid Products

Albrigi Tecnologie designs and manufactures stainless steel mixing systems engineered to guarantee efficiency, consistency, and process precision in handling liquid and semi-liquid products across the food, cosmetic, chemical, pharmaceutical, and biotech industries.

Each system is tailored to the specific characteristics of the product and production cycle—whether for static or dynamic mixing, homogenization, dissolution, or keeping substances in suspension. The configuration is determined based on viscosity, thermal sensitivity, and the desired processing results.

A wide array of mixing solutions is available, including inclined paddles, marine propellers, anchor agitators, coaxial mixers, emulsifiers, and combined systems—offering the best match for every technical requirement. All tanks can be equipped with instrumentation for temperature monitoring, variable-speed drives, integrated CIP connections, and customizable automation systems.

Internal surfaces are finished to High Clean Inside standards, ensuring hygienic design and easy maintenance. The compact layout, inspection-friendly construction, and mechanical reliability make these systems ideal for both industrial-scale production and pilot batches.

Materials used in manufacturing fully comply with current regulations for food contact and sensitive product applications, guaranteeing long-term safety and durability. Each system is the result of close collaboration with the customer's technical team, ensuring functional, high-performance solutions designed to deliver outstanding mixing quality.

Web site

https://tinyurl.com/44t9ubmk

Chemical Processing Systems – Safe and Custom Stainless Steel Solutions

Albrigi Tecnologie designs and manufactures advanced stainless steel systems for the chemical industry, combining engineered safety, chemical resistance, and customized performance. Each solution is developed in close cooperation with the client to ensure precise alignment with the required processes and the nature of the substances handled.

Our range includes tanks and reactors for storage, mixing, reaction, and transfer of liquid and semi-liquid chemicals—including aggressive, volatile, or thermally sensitive materials. Equipment can be configured with agitators, thermal jackets, sensors, certified valves, automation systems, and active or passive safety devices.

Every component is selected to guarantee long-term mechanical and chemical resistance. Internal surfaces are optimized for cleaning and contamination prevention, while all systems comply with relevant international standards. On request, we provide full traceability, technical dossiers, structural calculations, and certifications such as PED, ASME, and ATEX.

With over 35 years of expertise and installations worldwide, Albrigi is a trusted partner for chemical manufacturers of all sizes—offering modular, robust, and seamlessly integrable solutions. More than a supplier, we engineer confidence into every process.

Web site

https://albrigi.com/en/chemical

Wine Tanks and Cellar Systems – Tailor-Made Stainless Steel Solutions

Located in one of Europe’s most prestigious wine-producing regions, Albrigi Tecnologie has built outstanding expertise in designing and manufacturing stainless steel wine tanks and integrated cellar systems—solutions that now support wineries of all sizes across the globe.

Our product range covers every stage of the winemaking process: grape intake, fermentation, racking, storage, and aging. Each tank is custom-built and can be configured with cooling jackets, conical bottoms, discharge ports, floating or fixed lids, temperature and level sensors, mixing systems, and automation modules.

Surfaces in contact with wine are finished for maximum hygiene and easy cleaning, while advanced welding and sealing ensure long-term durability. Tanks are fully compliant with international food-contact material regulations.

Albrigi also offers a unique range of aesthetic customizations, including satin-polished, mirror-polished, and color-treated exteriors—designed with the food industry in mind and ideal for wineries that invest in enotourism, branding, or high-visibility cellar spaces.

Complete winery systems can be developed on request, including crushing lines, pipework, walkways, automation platforms, and software. Every project is engineered in close collaboration with the client to ensure a modular, scalable and high-performance solution—equally suited for boutique cellars or industrial-scale operations.

Web site

https://albrigi.com/en/wine

Stainless Steel Bioreactors – Precision Systems for Controlled Fermentation and Cell Culture

Stainless Steel Bioreactors – Precision Systems for Controlled Fermentation and Cell Culture

Albrigi Tecnologie designs and manufactures stainless steel bioreactors that offer reliable and highly customizable solutions for fermentation and cell culture processes in pharmaceutical, biotech, food, and environmental sectors.

Each system is engineered to ensure precise control over critical parameters such as temperature, pH, oxygenation, agitation, and pressure. Depending on the application, units can be equipped with thermal jackets, aseptic valves, digital sensors, magnetic or mechanical agitators, and automation modules for real-time monitoring and adjustment.

Design focuses on process homogeneity, ease of cleaning, and minimizing contamination risk. All materials used comply with current regulations concerning materials and articles intended to come into contact with food or sensitive substances, ensuring safety and long-term durability.

Albrigi bioreactors are tailored to specific applications, from the production of enzymes, bacteria, and probiotics to animal or plant cell culture. Available also for pilot plants and R&D, these systems are versatile, scalable, and supported by full technical documentation, structural calculations, and certifications such as PED and ASME.

Web site

https://tinyurl.com/4awbyuvb