- About us

- Company details

Since 1959, Tessitura Tele Metalliche Rossi (TTM Rossi) has been producing high-quality wire mesh and welded mesh in Italy, using materials such as stainless steel, special alloys, copper, bronze, brass, aluminium, iron, titanium, and synthetic wires. With over 60 years of experience and a strong focus on technology and innovation, TTM Rossi operates across 3 continents, serving diverse sectors including construction, structural reinforcement, air filtration and purification, mining, chemical-pharmaceutical, Oil & Gas, and industrial filtration.

Among its most advanced solutions is the FC Meltfilterband line, specifically designed for the filtration of molten materials like plastics. These filters, made from stainless steel and special alloys, guarantee consistent performance, long-lasting durability, and high reliability even under the most demanding operational conditions.

Thanks to its ability to customize products based on specific client requirements, TTM Rossi addresses complex challenges in the chemical, plastics, and petrochemical industries. All products are developed with a strong focus on sustainability, are compliant with UNI/EN standards, and reflect the company’s ISO 9001-certified commitment to quality.

TTM Rossi perfectly combines tradition and innovation, offering tailor-made filtration solutions that ensure operational efficiency while respecting the environment—an embodiment of Made in Italy excellence for the global market.

Year of establishment:

1959

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2024

Export turnover:

From 5 to 15 million Euro

Activities:

Weaving of textiles

Manufacture of fabricated metal products, except machinery and equipment

Manufacture of wire products

Manufacture of other fabricated metal products nec

- Contact Information

- Business Proposals

Company:

Tessitura Tele Metalliche Rossi s.r.l.

Web site:

Address:

VIA DELL'ARTIGIANATO 16

City:

VILLA GUARDIA VILLA GUARDIA (CO)

Zip Code:

22079

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

FACADES_WASTE TO ENERGY PLANT

Quadra mesh represents the foundational element of the MetalDesign collection dedicated to architecture

field. The warp and weft stainless steel wires intersect each other with regularity, creating a consistent square

mesh.

Functional, chromatically neutral, formally essential, transparent, elegant, rigorous:

these are the primary attributes that define Quadra 3x3.

Its structural rigidity allows for the creation of sharp geometric cuts and facilitates

its application to surfaces characterized by sharp edges.

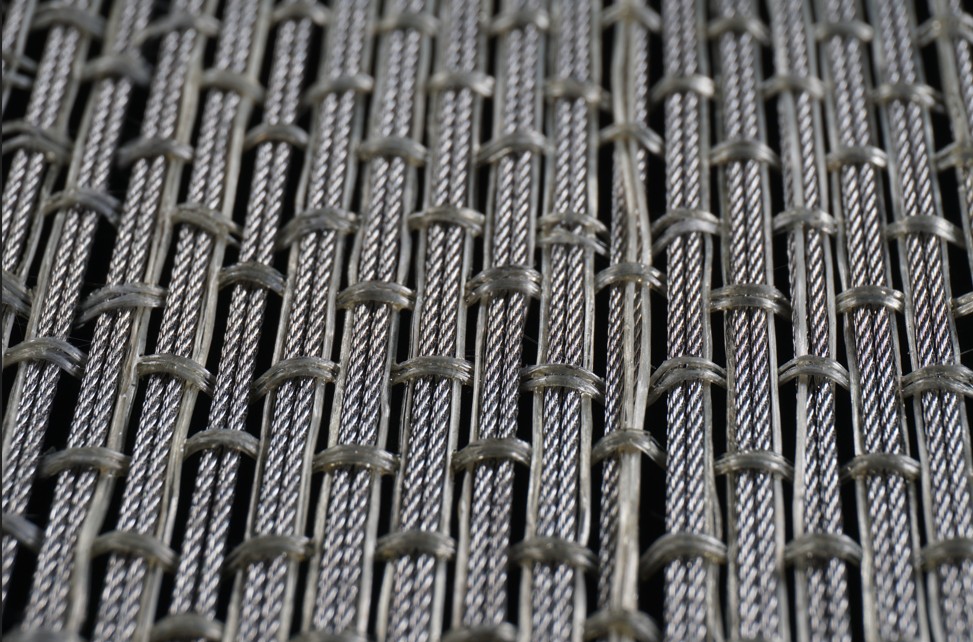

INDUSTRIAL FILTER

TTM Rossi is dedicated to delivering high-quality service through the production of precision metal meshes, while supporting its customers across a wide range of applications. The company operates with a strong focus on environmental responsibility and sustainable development, using raw materials that maintain their physical and mechanical properties, and are infinitely recyclable and environmentally friendly.

Thanks to a 100% Made in Italy production process and ISO 9001:2015 Quality Certification, TTM Rossi ensures full in-house control over every stage of manufacturing—from metal fabric weaving to the creation of custom panels, shaped parts, and discs.

TTM Rossi metal meshes are known for their performance, versatility, and reliability, serving multiple industrial sectors including:

- Mining

- Chemical and Pharmaceutical Industries

- Oil & Gas

- Industrial Filtration

- Automotive

- PPE Protection (Personal Protective Equipment)

- Household and Food Applications

Innovation, experience, and a highly skilled team are the foundation of TTM Rossi’s commitment to offering tailored solutions that meet the evolving needs of the global market. The company continuously invests in research and development to stay ahead in terms of technology, sustainability, and customer satisfaction.

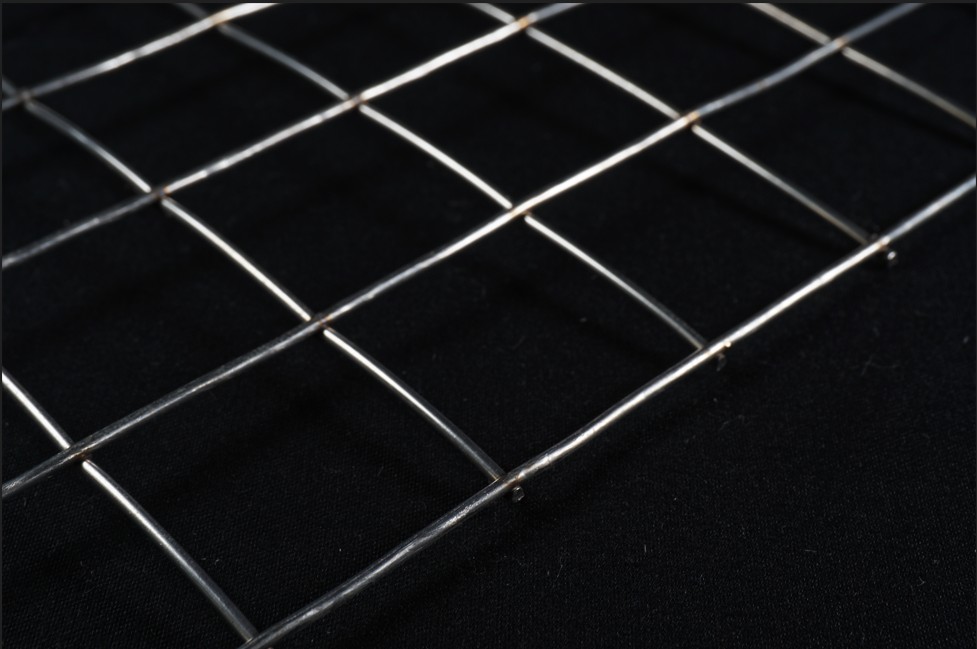

ELECTRO WELDED MESH

TTM Rossi electro-welded mesh represents a

high-quality solution for the construction industry,

surpassing common market standards.

Used as light, non-structural reinforcement, it

effectively prevents the formation of cracks in rapidhardening

concrete mixes, thin cement screeds, subfloorings,

and plasters (both vertical and horizontal),

improving resistance to thermal stresses. Their

versatility also makes them suitable for adhesive

laying on existing screeds or floors, increasing the

cohesion and flexibility of the adhesive-tile system.

HIGH-STRENGTH UNIDIRECTIONAL GALVANISED STEEL REINFORCEMENT FABRIC FOR STRUCTURAL STRENGTHENING

The unidirectional technical reinforcement fabric is made of high-strength galvanized filaments. Specifically

designed for use with inorganic matrices, it is applied in the structural consolidation of masonry works,

reinforced concrete elements, and prestressed reinforced concrete structures.

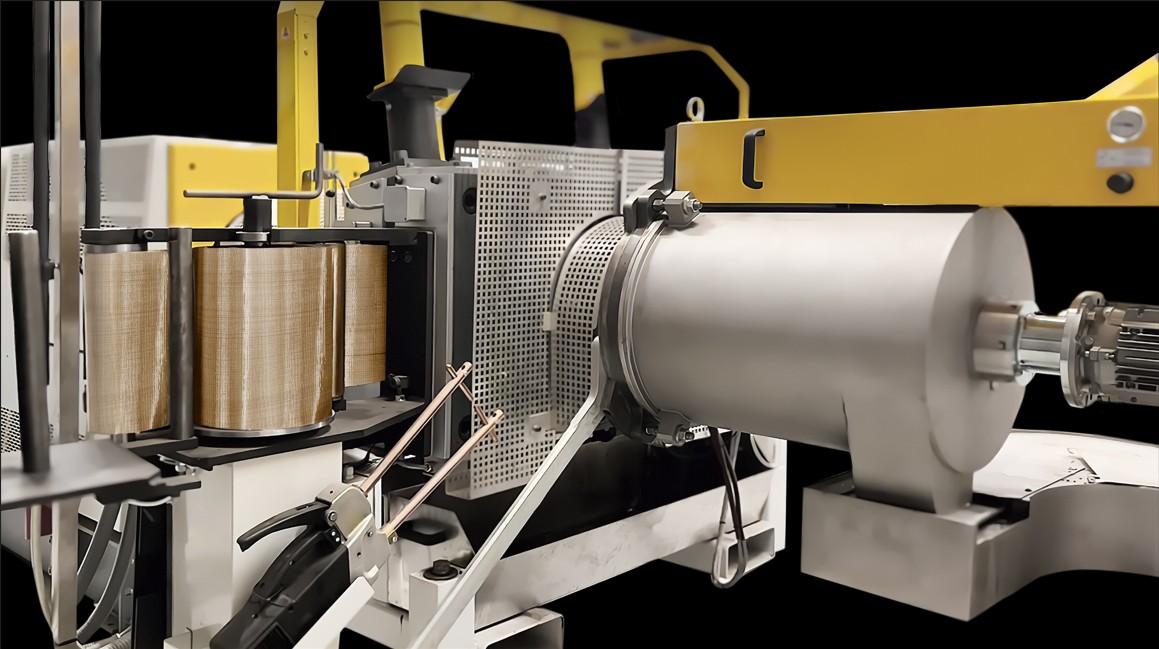

FC_MELT FILTER BAND_AUTOMATIC SCREENCHANGER

FC_MeltFilterBand: the optimal filter for automatic screen changers in plastic recycling

The FC_MeltFilterBand filter belt is the ideal solution for automatic screen changer systems, widely recommended by leading manufacturers in the industry. Specifically designed for plastic recycling, it ensures high performance, durability, and maximum filtration efficiency.

Reliability and innovation are the result of a highly qualified team, constantly engaged in research and development of advanced technologies to meet the ever-evolving needs of the recycling industry.

Web site

https://www.meltfilterband.com/