- About us

- Company details

LAIP is a modern Italian company based in Prato, the heart of the textile industry, which for 60 years has produced dyeing machines of a high technical and technological quality. Its production range includes autoclave for cones, tops and fiber, air water flow, soft flow and over flow.

These machines are designed to guarantee a high performance level during the whole dyeing process with the maximum respect for the environment. The accurate regulation of power and water supply, the automatization of the working process and the easy use of these machines contribute to a real reduction of prime costs.

Year of establishment:

1967

Number of employees:

FROM 20 TO 49 EMPLOYEES

Annual turnover:

between 5 and 15 million Euro

Reference year of turnover:

2019

Export turnover:

From 5 to 15 million Euro

Activities:

Manufacture of other general-purpose machinery

Manufacture of machinery for textile, apparel and leather production

Manufacture of textile machinery

- Videos

- Catalogue

SINGTEX, leader in functional fabrics, enthusiastic for BEAM Dyeing machines from LAIP

Complete 4.0 Production Line for Fiber and Tow Dyeing - LAIP

JET 250 HT dyeing machines for functional fabrics at Eurojersey, Italy - LAIP

Fabric Sample Dyeing Machine, Up to 20 meters - absolute Reproducibility │MINI JET by LAIP

Completly Automated Dyeing Lines for Fiber, Solutions in textile recycling and recovery process LAIP

- Contact Information

- Business Proposals

Company:

L.A.I.P. S.R.L.

Web site:

Address:

VIA S. PAOLO 405

City:

PRATO (PO)

Zip Code:

59100

E-commerce:

Social media:

Tag:

No business proposals uploaded

- Map

JET 250HT Fabric dyeing machine

The Jet that prevents machine downtime, while guaranteeing even and flawless dyeing.

No defect, claim or declassification of product. This is why Eurojersey has chosen the JET 250 HT for Sensitive Fabrics, the internationally acclaimed brand for activewear, streetwear and swimwear.

1. Avoids machine downtime while also guaranteeing uniform and flawless dyeing

2. Easy operation and maintenance

3. The low liquor ratio results in the saving of around 20% of water, with a significant environmental and economic impact, for a healthier end product and more eco-compatible process

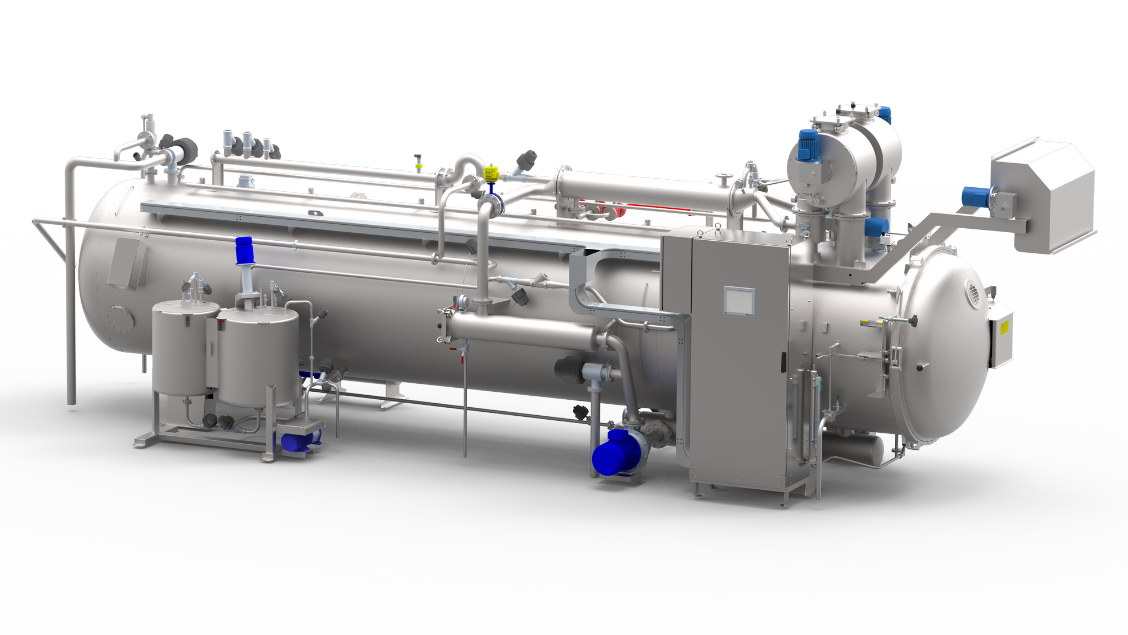

198HT Yarn dyeing machine

Vertical air cushion yarn dyeing machine in bobbins, tops, tows and loose fibers of natural and synthetic fibers.

1. Reliability and the guarantee of optimal dyeing: homogeneous flow distribution and optimisation of operating phases for shorter process times

2. Flexible load capacity with constant liquor ratio. Can be fitted with different types of material carriers for yarn in bobbins, hanks, fiber, tow, tops.

3. Attention to consumption and respect for the environment

4. The high performance flanged tube bundle exchanger external to the machine ensures easy maintenance and internal inspection.

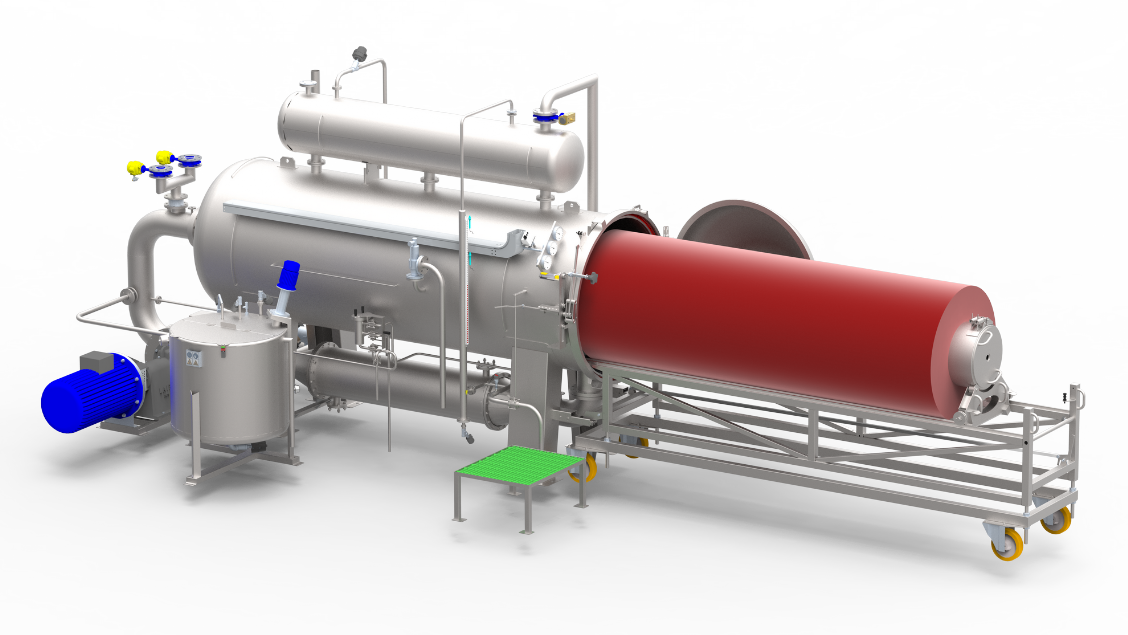

Complete 4.0 production line

Proud to have supplied “Garanti İplik”, one of Turkey’s most important cotton spinning plants, with the complete fiber dyeing line Automation 24 hours a day, 7 days a week, for the fully integrated and digitalised management of the industrial 4.0 cycle. Production and energy efficiency achieved thanks to the plant’s optimal performance.

Web site

https://laip.it/en/machines/198-ht/

NAUTILUS Fabric dyeing machine

Ideal machine for dyeing delicate fabrics with a horizontal conformation and excellent energy performance levels.

1. The only machine with a double belt: better circulation for exceptional dyeing

2. Flexible load capacity with constant liquor ratio: the liquor ratio is kept constant by the maximum fabric load for up to 40%. The specific drop folder enables correct fabric placement on the conveyor belt, for increased load capacity.

3. Low water consumption guaranteed by a maximum liquor ratio of 1:4. Less steam for lower power consumption, up to – 30% KW.

BEAM Fabric dyeing machine

Beam dyeing machine suitable for delicate knitted or woven fabrics.

1. Superlative technical performance and optimisation of production times. Centrifugal circulation pump with liquor inversion or a high efficiency single-direction centrifuge. Speed adjustment by means of inverter, for optimal dyeing liquor flow adjustment. Differential pressure or consistent flow rate. Technology developed to reduce dyeing times.

2. Attention to consumption and respect for the environment

3. Reliability and the guarantee of optimal dyeing

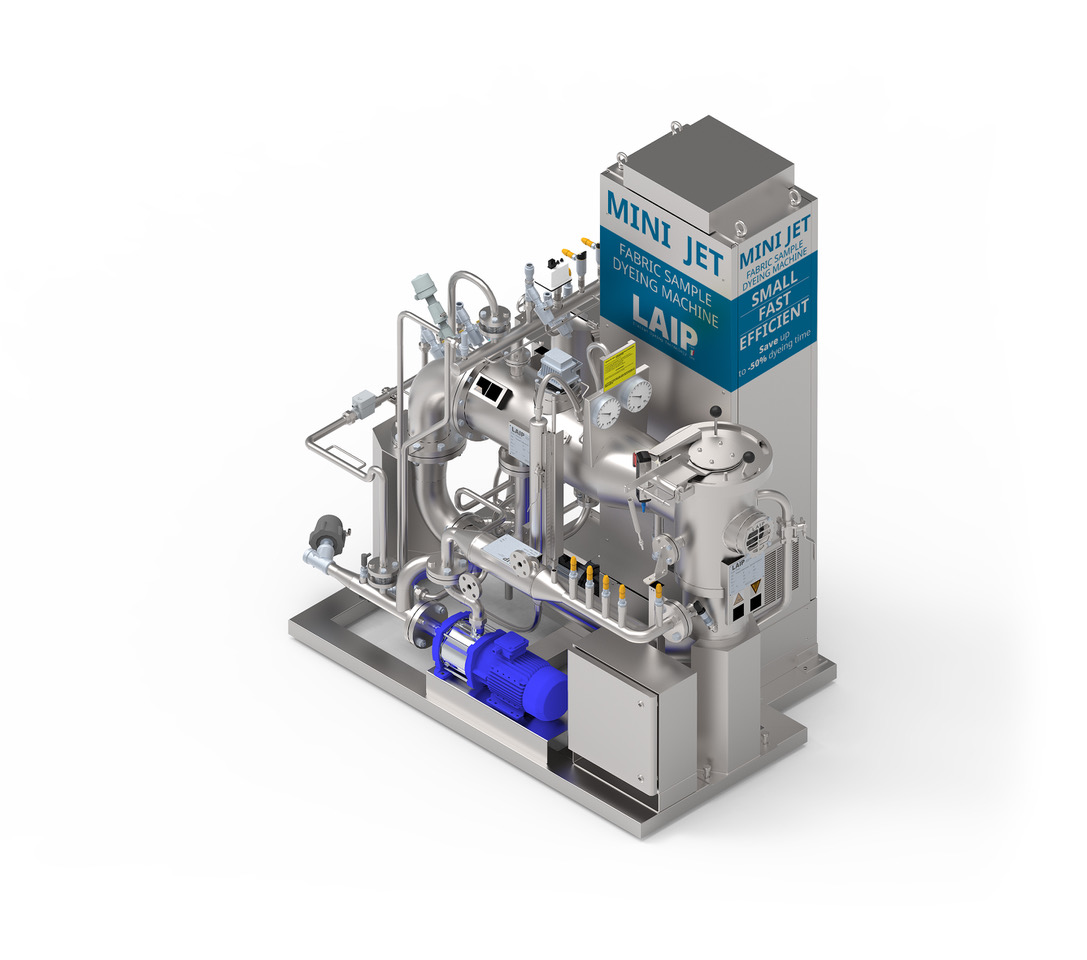

Mini Jet - Repeatability on production machines, perfect for dyeing individual fabric samples up to 20 meters.

1.MINI JET allows internal dyeing of small fabric lengths, from 5 to 20 meters per color, making it ideal for testing garments and developing samples without relying on external dyeing.

2. Thanks to the high fabric circulation speed, MINI JET enables multiple dye tests in a single day, increasing productivity and reducing dyeing time by up to 50%.

3. Professional results and perfect reproducibility: dyeing quality is on par with production machines. Reproducibility is guaranteed, ensuring consistency between lab tests and full-scale production.