- About us

- Company details

TECHNOLOGICAL INNOVATION BASED ON EXPERIENCE

Acctive for over thirty years in the supply of systems and products for industrialised construction, B.S. Italia S.p.A. can draw on the vast pool of experience gained over time thanks to its local and international customers. A strategy – aimed at solving different problems and at optimising production processes through new ideas, specialisation, testing and direct experimentation on site – that allows the company to offer innovation and quality.

B.S. Italia S.p.A. also expanded its international business interests by establishing its presence in the Mercosur area through the opening of a subsidiary company named B.S. Italia do Brasil in the state of São Paulo, Brazil.

B.S. Italia‘s solutions for the connection, support, anchoring, lifting, and safety of precast concrete elements are based on the logic of improvement, simplification, industrialisation of production, total quality of the result, and speed of use. Components designed to guarantee the flexibility necessary to adapt perfectly to the needs of the architectural project, even within a serial production: millimetric adjustability, in some cases even on the three Cartesian axes, is an essential prerogative.

B.S. Italia products are equipped with intelligent safety devices, which favour error-proof use and, consequently, enhance safety on the building site. Particular attention is paid to solving problems arising from seismic actions, with the production of anti-seismic supports and connections. They are covered by international patent rights, protecting exclusivity, and have passed IQNet, ISO 9001, EN 1090 and CE quality certifications or comply with the most stringent international standards.

ctive for over thirty years in the supply of systems and products for industrialised construction, B.S. Italia S.p.A. can draw on the vast pool of experience gained over time thanks to its local and international customers. A strategy – aimed at solving different problems and at optimising production processes through new ideas, specialisation, testing and direct experimentation on site – that allows the company to offer innovation and quality.

B.S. Italia S.p.A. also expanded its international business interests by establishing its presence in the Mercosur area through the opening of a subsidiary company named B.S. Italia do Brasil in the state of São Paulo, Brazil.

B.S. Italia‘s solutions for the connection, support, anchoring, lifting, and safety of precast concrete elements are based on the logic of improvement, simplification, industrialisation of production, total quality of the result, and speed of use. Components designed to guarantee the flexibility necessary to adapt perfectly to the needs of the architectural project, even within a serial production: millimetric adjustability, in some cases even on the three Cartesian axes, is an essential prerogative.

B.S. Italia products are equipped with intelligent safety devices, which favour error-proof use and, consequently, enhance safety on the building site. Particular attention is paid to solving problems arising from seismic actions, with the production of anti-seismic supports and connections. They are covered by international patent rights, protecting exclusivity, and have passed IQNet, ISO 9001, EN 1090 and CE quality certifications or comply with the most stringent international standards.

Year of establishment:

1990

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2023

Export turnover:

From 750.000 to 2.5 million Euro

Activities:

Manufacture of fabricated metal products, except machinery and equipment

Specialised construction activities

Architectural and engineering activities and related technical consultancy

- Videos

- Catalogue

Safelift is a universal lifting system: easy and fast to use, extremely safe

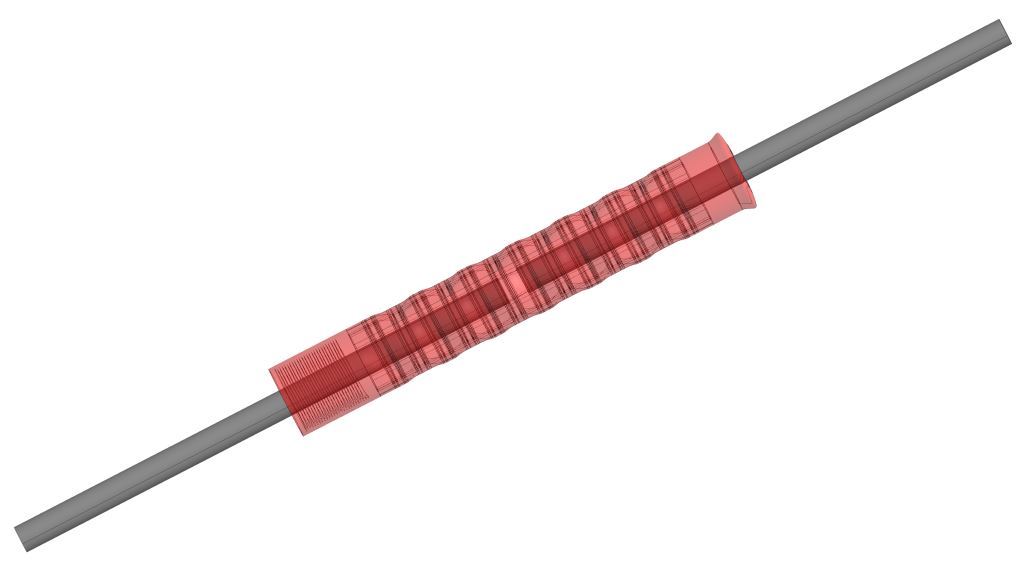

he RS Continuity Connection, a patented seismic-resistant system for connecting concrete structures, guarantees the direct transfer of forces between two reinforcement bars and achieves PERFECT EMULATION OF THE CAST-IN-PLACE STRUCTURES. This innovative result is achieved thanks to an innovative adjustable device (adjustment foot) placed dry between the concrete structures to be connected, which allows the precast structures to be set up without any provisional shoring or support work.

- Contact Information

- Business Proposals

Company:

B.S. ITALIA S.P.A.

Web site:

Address:

VIA STEZZANO 28

City:

ZANICA (BG)

Zip Code:

24050

E-commerce:

Tag:

No business proposals uploaded

- Map

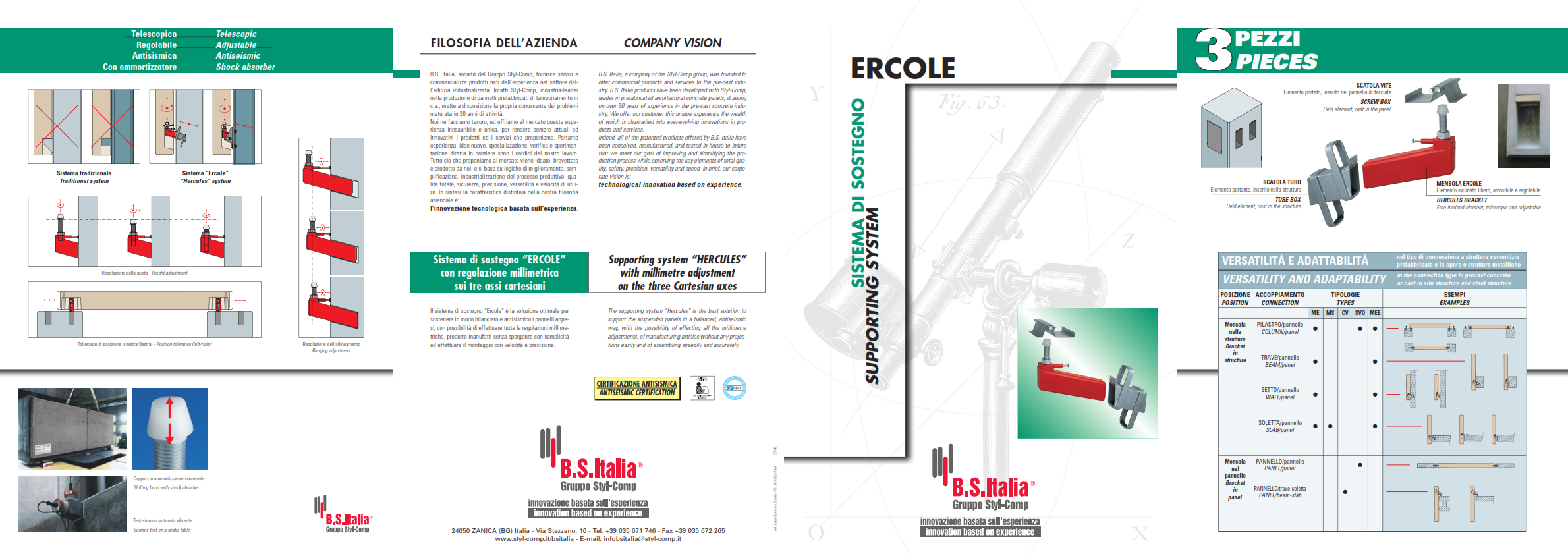

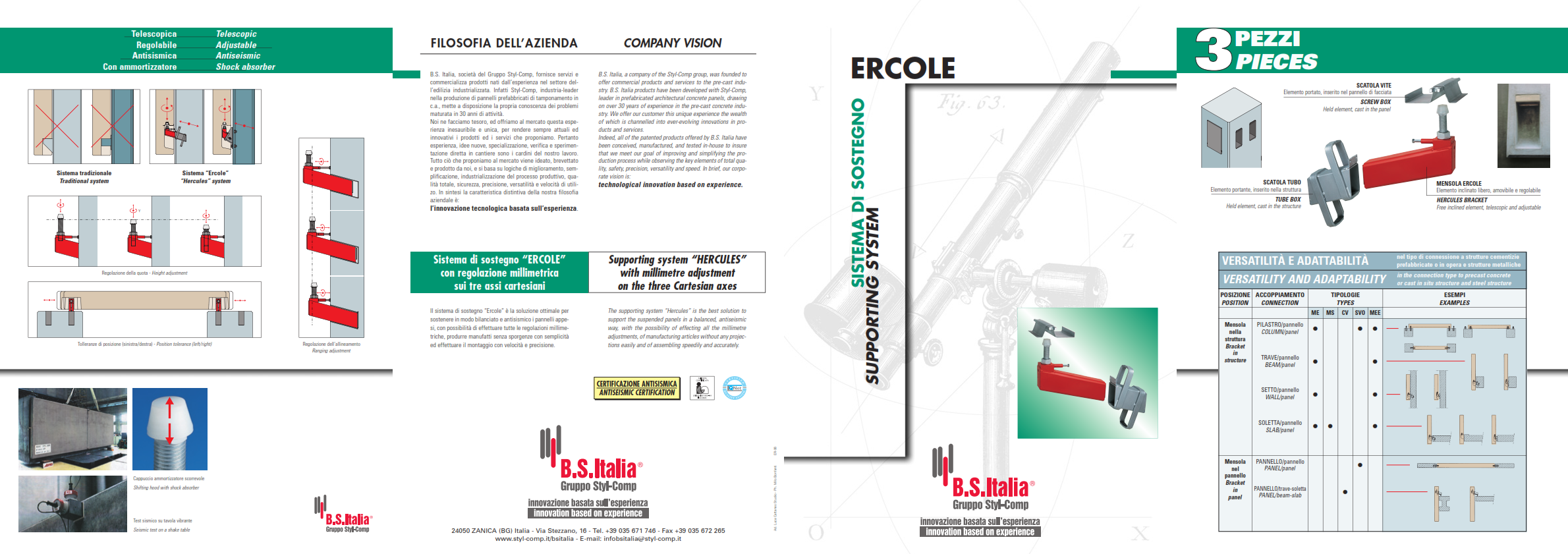

Supporting system , regolation on three cartesian axis

Ercole is the system to support panels in a balanced and anti-seismic way For precast concrete panels. It is available in embedded version, for precast concrete solutions, and flush mounted version, for steel or concrete structures. It allows both millimeter adjustments along the three Cartesian axes and the manufacturing of concrete items without projections.

Adjustable:Bracket for supporting precast concrete panels it lets you adjust to millimetre along the three Carthesian axes.

Versatile: Bracket for supporting precast concrete panels it comes in many versions and can be applied to any load bearing structure, whether precast or cast-in-place, vertical, horizontal or cantilevered, in reinforced concrete or metal, of any size or thickness. In fact, the ERCOLE Bracket for supporting precast concrete panels can be set at right-angles or be parallel to the panel it has to support, can be aligned or otherwise, adjacent to or apart from the structure.

Cost-effective of Bracket for supporting precast concrete panels the low cost of this system can be appreciated at all stages in the production process;

design: the system Bracket for supporting precast concrete panels comes in a wide range of pre-calculated certified variants, ready to be used, and so no design calculations are necessary;

production: no projecting parts makes it easy to move columns and precast concrete panels;

transport: the absence of protrusions simplifies the transport of columns and precast concrete panels ;

installation: the dry assembly of the parts for supporting precast concrete panels makes for fast insertion in the structure, without the need for welding or bolting, meaning fewer skilled workers are required

Supporting system , regolation on three cartesian axis

Ercole is the system to support panels in a balanced and anti-seismic way For precast concrete panels. It is available in embedded version, for precast concrete solutions, and flush mounted version, for steel or concrete structures. It allows both millimeter adjustments along the three Cartesian axes and the manufacturing of concrete items without projections.

Adjustable:Bracket for supporting precast concrete panels it lets you adjust to millimetre along the three Carthesian axes.

Versatile: Bracket for supporting precast concrete panels it comes in many versions and can be applied to any load bearing structure, whether precast or cast-in-place, vertical, horizontal or cantilevered, in reinforced concrete or metal, of any size or thickness. In fact, the ERCOLE Bracket for supporting precast concrete panels can be set at right-angles or be parallel to the panel it has to support, can be aligned or otherwise, adjacent to or apart from the structure.

Cost-effective of Bracket for supporting precast concrete panels the low cost of this system can be appreciated at all stages in the production process;

design: the system Bracket for supporting precast concrete panels comes in a wide range of pre-calculated certified variants, ready to be used, and so no design calculations are necessary;

production: no projecting parts makes it easy to move columns and precast concrete panels;

transport: the absence of protrusions simplifies the transport of columns and precast concrete panels ;

installation: the dry assembly of the parts for supporting precast concrete panels makes for fast insertion in the structure, without the need for welding or bolting, meaning fewer skilled workers are required

Seismic connecton system

The innovation of the new B.S. Italia CONTINUITY CONNECTION SYSTEM with seismic-resistant INJECTION SLEEVE for prefabricated concrete connections overcomes all the limitations inherent in connections between concrete structures today, making it possible to achieve the fundamental objectives of good structural design and allowing for PERFECT EMULATION OF CAST-IN-PLACE STRUCTURES for continity connection.

Developed for connecting prefabricated columns and foundations, between two portions of prefabricated columns, between walls and columns or between columns and beams, it is able to create a mutual interlocking bond between the parts, restoring the structural continuity of the reinforcement bars without requiring them to overlap, introducing new and interesting innovations of continuity connection into the world of prefabrication. By exploiting the concept of adherence (by means of a cement matrix) between the reinforcement bars and the SLEEVE, thus guaranteeing the occurrence of a situation of perfect continuity between concrete products, typical of in-situ concrete structures, representing an ideal solution from the point of view of seismic performances in reason of the continuity connection . On the one hand, the SLEEVES make the use of the system more agile and immediate, speeding up and favouring the precision of assembly, while on the other hand they allow engineering optimisation of the behaviour of the metal inserts inside the concrete structures. Filling the sleeve by injection to make a perfect continuity connection , as well as the space between the precast elements , is then completed on site by wet sealing using B.S. Grout, a high-strength, doubly expansive mortar (during setting and hardening) created in cooperation between Mapei and B.S.Italia and specifically designed to give the RS continuity connection high performance.