- About us

- Company details

GNA SRL is a company specialized in the production of working and packaging systems for products of food and no-food industry.

Each machine or plant is made of high-grade materials and is the result of research committed to achieve the state-of-the-art technological level.

The experience gained through several years of direct cooperation with our customers has taught us the importance of promptly meeting our customer needs and of offering them , by means of structural analysis, project development, business consultancy, pre and post-sales service, versatile solutions to satisfy all their requirements.

Established in 1987 in Bologna, the heart of the packaging valley, GNA Srl began its activity as a subcontractor of big manufacturers of packaging solutions (IMA - GD-Coesia Group) but very soon developed machines with its own brand.

The company is today specialized in the production of packaging systems for products of food and no-food industry, its main core business is the development of solutions for packaging fresh and fresh-cut produce.

With its strong presence on both domestic and international markets and with its know-how, the company can count on a wide range of machines.

Year of establishment:

1987

Number of employees:

FROM 10 TO 19 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2022

Export turnover:

Not available

Activities:

Manufacture of packing and wrapping machinery

Rental and leasing of other various machinery, equipment and tangible goods nec

- Contact Information

- Business Proposals

Company:

GNA SRL

Web site:

Address:

VIA PROGRESSO 15

City:

OZZANO DELL'EMILIA (BO)

Zip Code:

40064

Social media:

Tag:

No business proposals uploaded

- Map

Horizontal Flow Pack Packaging Machine Mod. Squalo

The horizontal electronic SQUALO packaging machine is one of the most powerful flow pack machines of GNA srl range.

It is made of AISI 304 stainless steel and aluminium and has rounded corners to prevent product build-ups and allow easier machine cleaning. It is fit for being used in many sectors such as fruit & vegetable, bread-making, dairy, confectionery, sausage meats, pasta, etc.

Thanks to its high versatility, flexibility and reliability, it can pack any type of solid product, whether food or not and reaches a max speed of 150 cycles/min.

Squalo is extremely modular and may be customized by means of a two-volume structure that permits to separate the mechanical-electrical area from the work control area by installing overhanging units.

Two brushless motors and the Touch Screen panel guide the operator throughout the main operations that entail preparing and storing data, to operate the machine.

Main Technical Data:

Speed (cycles per minute): min 70 – max 150

Film width: max 800 mm

Bag length: min 50 - max 500 mm

Product width: min 70 - max 300 mm

Clearance between jaws: from 160 to 210 mm

Electrical consumption: 3 KW

Compressed air consumption: 15 NL/min

Horizontal Flow Pack Packaging Machine Mod. AV550 -

AV550 is a packaging machine fitted with a lower film reel, therefore the product is already in the film when entering the machine. This feature together with the machine ability to work with variable pitch, allows to pack challenging products like cabbage, cauliflower, broccoli, iceberg, salad heads or produces in stalks like celery, fennel, leek, even contemporarily; bakery products, sausage meat. This machine is able to flow pack and shrink cm 20x30, cm 30x40, cm 30x50 carton boxes as well. A sophisticated, but at the same time easy-to-use electronics, controls all the machine functions and the accessories as well: sealing jaws for special applications, kit for shrink film, modified atmosphere option. By means of a “beam” photocell the machine easily detects wide leaves products or products in bunches, like banana. The feeding system consists of a conveyor belt, already included in the standard machine. AV550 can process different type of plastic films, like polypropylene, laminated one-side or both-sides heat sealable, shrink film.

Main technical data:

Speed (cycles per minute): max 60 - 70

Film width: max 1100 mm

Product width: min 120 – max 300 mm

Product length: min 120 - max 800 mm

Clearance between jaws: min 30 – max 200 mm

Electrical consumption: 3,5 KW

Compressed air consumption: 270 NL/min

Vertical packaging machine VFFS Mod. Robinia for continuous motion

Robinia is the innovative and high-performance continuous motion VFFS machine by GNA srl, suitable for packaging both dry and wet products in bags of different sizes and shapes.

Designed to deliver bags up to 350 mm wide with a maximum packaging speed 100 Rpm, it is build with an open frame design and guarantees excellent sanitization even in difficult environments. The new electronic platform allows Robinia to operate in 'box motion' mode with higher sealing times and pressure, so to obtain the same performance as a machine with rotary jaws, when speed becomes an essential asset.

The multi-protocol operator panel with 10" screen, fully integrated inside the machine, grants to satisfy all the functional needs, such as remote connection of the machine to external systems, for diagnostic and remote assistance purposes, and connection to MES (Manufacturing Execution System) for the production’s management and control. All the documentation (wiring diagrams, use and maintenance manual and exploded views) can also be consulted from the operator panel.

Special Features

4 Servo Motors

Vertical Sealing via warm air

Film pulling via integrated suction system

Fully integrated Multi-Protocol Operator Panel, 10” screen

New electronic system

Vertical Box Motion Mode ensuring high speed

MES (Manufacturing Execution System) connection

Remote connection for diagnostic and service

Stainless steel AISI 304 frame

Main technical data:

Speed (cycles per minute): 100 rpm

Film width: Max 750 mm

Bag length: min 350 max 500 (mm)

Bag width: 350 mm

Electrical consumption: 4 KW

Compressed air consumption: 120 NL/min

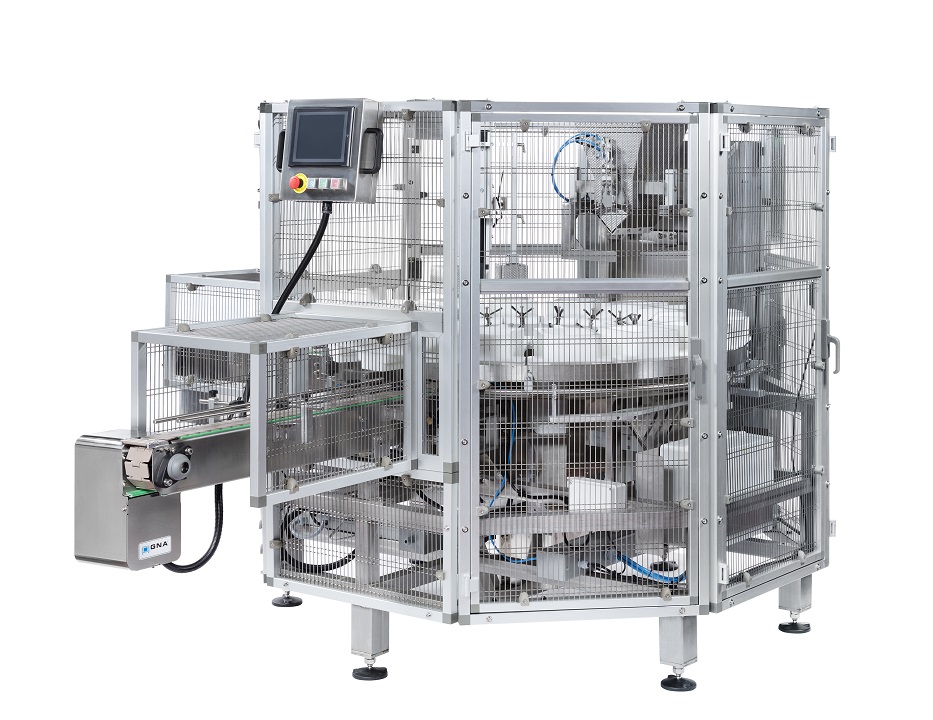

Filling Carousel Mod. V80-S

Thanks to its innovative technical features, which highlight accuracy and efficiency, the Tray Filler mod. V80/S represents the perfect solution for filling trays of various sizes and shapes (round, rectangular, square). The tray filler V80/S, is designed with octagonal frame, which permits to fully customize the positioning of the optional belts.

AISI 304 stainless steel is the only component of the structure, the panels and boards of the machine. It allows a high sanitization and cleaning standard. According to the different needs, several accessories are available to be added to the V80/S basic model.

Brushless engines allow high performances:

- High speed

- Accuracy, by the rotational movement of the aluminum disc and pressing through a double-pusher.

Technical features

• 80 ppm (mechanical speed, machine empty without any product), the real speed depends on the product type and on the weigher drops.

• N° 1 tray format included.

• 16 filling stations with quick buckets change by means of a fixed knob.

• Disc handling by means of brushless motor coupled with cycloidal reduction gear mod. Sumitomo F4C-D SERIES.

• Circular protection guide fixed to the disc frame, suitable to contain the product during rotation.

• Touch screen interface, 8”size LCD. Easy interaction of main controls and simple errors and alerts management.

• Timing hopper for reduction of product drop time.

• Aluminum disk, treated and assembled according to the current regulation on food safety.

• Double pressing device handled by brushless motors.

• Optional infeed/outfeed belts for trays transport: several belts configurations possible depending on product flow.

• Protective covers of stainless steel net with aluminium edges.

Main technical data:

Speed (cycles per minute): max 80

Tray height: min 40 - max 110 mm

Electrical consumption: 3 KW

Compressed air consumption: 200 NL/min

Boxes Filming Machine Mod. Wrap Box 600

Wrap-box 600 is a machine able to put covers of micro or macro perforated film on carton or wooden boxes using hot glue; changing the cutting device (which is an option to the standard machine), our wrap box can also be used to apply covers of film, extruded net + film, paper + cotton net. In this way you will obtain a wrapped box that perfectly protects the product contained in it by means of the cover glued onto the long sides of the box.

The film reel is placed in the upper frame of the machine and unwinds itself in the same running direction of the boxes (that is narrow side). This allows the application of pre-printed films or pre-printed net + films by means of the print registration option.

The control panel run by PLC visualizes all programmable functions, parameters and formats according to boxes sizes cm 20x30, 30x40, 30x50, 40x60.

Format changeover is managed automatically by PLC; the different width, height and glue positioning changes are entered into the size together with film length, avoiding any manual adjustment.

Main technical data:

Speed (cycles per minute): Up to 28/30

Film width: max 650 mm

Box length: max 600 mm

Box width: max 400 mm

Box height: max 220 mm

Clearance for the use as roller track: max 300 mm

Electrical consumption: 4.5 KW

Compressed air consumption: 100 NL/min