- About us

- Company details

RF Systems designs and manufactures Radio Frequency machines for the textile and food industry, that speed up and enhance drying and thermal processes, cutting energy consumption and operating costs.

Year of establishment:

2018

Number of employees:

FROM 3 TO 9 EMPLOYEES

Annual turnover:

between 2.5 and 5 million Euro

Reference year of turnover:

2018

Export turnover:

From 2.5 to 5 million Euro

Activities:

Manufacture of machinery for food, beverage and tobacco processing

Manufacture of textile machinery

Manufacture of leather machinery

Manufacture of plastics and rubber machinery

Manufacture of all other various special-purpose machinery nec

- Contact Information

- Business Proposals

Company:

RF SYSTEMS S.R.L.

Web site:

Address:

VIA PEZZI 47/49

City:

SOLAGNA NOVE (VI)

Zip Code:

36055

Social media:

Tag:

No business proposals uploaded

- Map

Food Dryer

The drying process plays a decisive role in creating high-quality products. Radio Frequency dryers have been developed on purpose to remove the excess moisture content from many substrates in minutes, replacing slow and expensive conventional drying systems.

The RF technology is particularly suitable for the post-baking drying of baked products (biscuits, crackers, crispbread, etc..). Indeed, final moisture reduction and levelling is a difficult task to achieve in baking ovens: due to the crust formation during baking, moisture evaporation takes about 60% of the energy of the entire process and about 30% of the overall oven length.

Differently, Radio Frequency is selective towards water and ensures drying in minutes with no surface over-baking or excessive colouring.

Hundreds of RF post-baking dryers have been installed in industrial bakeries in the last 40 years, making it the most popular RF drying application in the food sector.

Radio Frequency Defroster

Conventional defrosting systems (still air thawing, forced air/blast thawing, water sprinkling, water immersion systems, etc..) are slow and often generate product waste due to the poor process control.

Differently, RF defrosting is an endogenous and instantaneous method that delivers the product ready for the next step in a few minutes: the product to be defrosted, either in blocks or IQF, is placed on the conveyor belt of the RF machine and is submitted to rapid dielectric heating that brings its temperature just below the melting point of water, with no drip loss or bacterial deterioration.

In this way, other than saving time and preserving quality, last-minute orders can be easily managed and product waste is completely avoided.

Furthermore, being a continuous and in-line process, multiple handling is eliminated, with huge savings in labour cost.

Radio Frequency Pasteurizers

The outstanding benefits of the RF technology can also be achieved in the disinfestation, sanitization and pasteurization of various food commodities, intermediates or finished products, either in bulk or packaged.

Food processors often rely on steam or other conventional heating systems (mostly based on hot air circulation or surface heat exchangers) for the microbial inactivation/stabilization processes: the heat transfer is generally slow and uneven, severely damaging the physical, sensorial and nutritional properties of the product.

Differently, the ability to penetrate deep inside the product mass and generate heat evenly and instantly is, at the same time, the main characteristic and the main benefit of RF heating. Practically, in RF pasteurizers the product is submitted to a rapid and gentle dielectric heat treatment for a few minutes, that leads to live cell destabilization and microbial inactivation. In this way, food substrates can be sanitized while preserving their physical, sensorial and nutritional properties.

RF machines are rather small in size and modular, so that additional production capacity can be easily added at any time. This makes convenient the integration of the RF technology into existing production lines.

Adjustable parameters in the PLC allows the operator to set the appropriate process recipe for each product.

Either batch or conveyorized model RF machines are available, depending on the product/process type and production capacity requirements. The machines and their ancillary equipment are designed and supplied according to the customers specific requirements.

Textile dryer

Accurate moisture control is essential to obtain a high-quality yarn. Our TD dryer ensures a high and consistent product quality thanks to the PLC that automatically adjusts the appropriate RF energy delivery during the drying process.

The process only takes a few minutes and provides excellent drying uniformity.

The process is carried out in-line with water evaporation rates from 20 Kg/h to 120 Kg/h, depending on the RF generator size, so to satisfy the requirements of any size dye-house.The equipment configuration is extremely flexible and additional modules can be added to cope with higher capacities. The machine is equipped with the X-Dry cooling system and the Hybrid version is available on request.

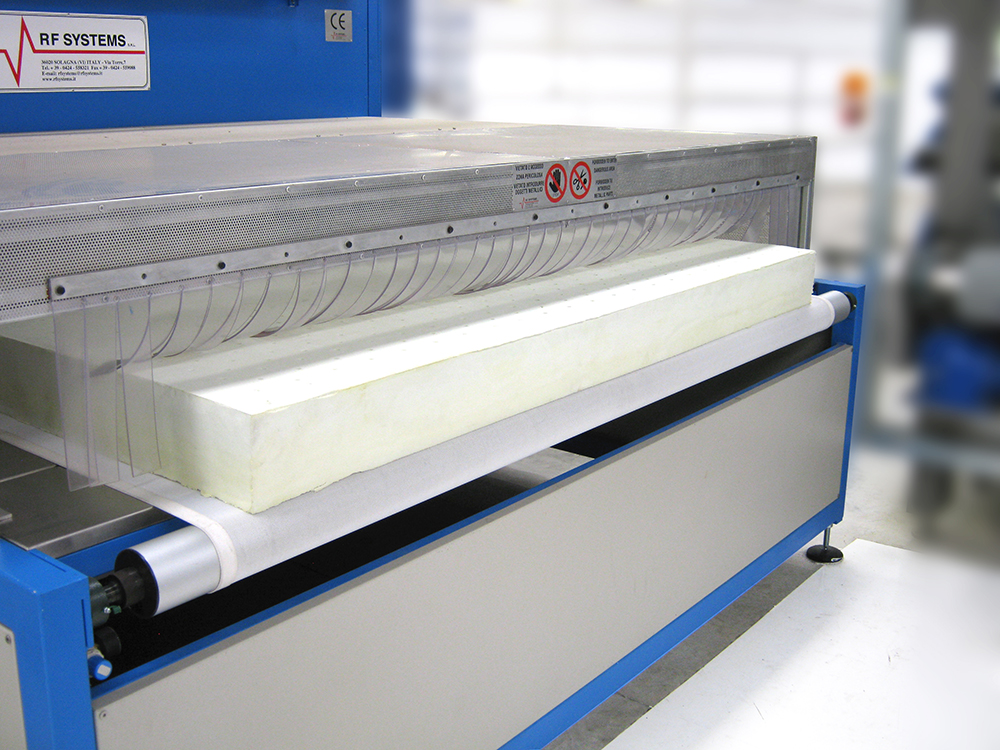

Dryers and vulcanizers for latex foam

The Radio Frequency technology is based on electromagnetic fields that generate heat within the product mass and allow rapid vulcanization in a few minutes. Being an endogenous process, no metal pins or expensive metal moulds are required: in fact, the product can be vulcanized in light and cheap plastic moulds, allowing for a more flexible design and easier product stripping.

The drying process can be carried out very quicky as well: the water evaporates in the surface as in the core at the same time (also in shaped items), leaving the product uniformly dried, without yellowing or wet spots.

The final outcome is a higher quality product at a lower cost, along with a huge increase in the production throughput.

All major latex foam producers worldwide are currently using RF Systems machines in their production facilities.